Torch Applied Concrete Roof Modified Bitumen SBS Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick DetailsType:

Waterproof Membrane, Waterproof membrane Place of Origin: China (Mainland)

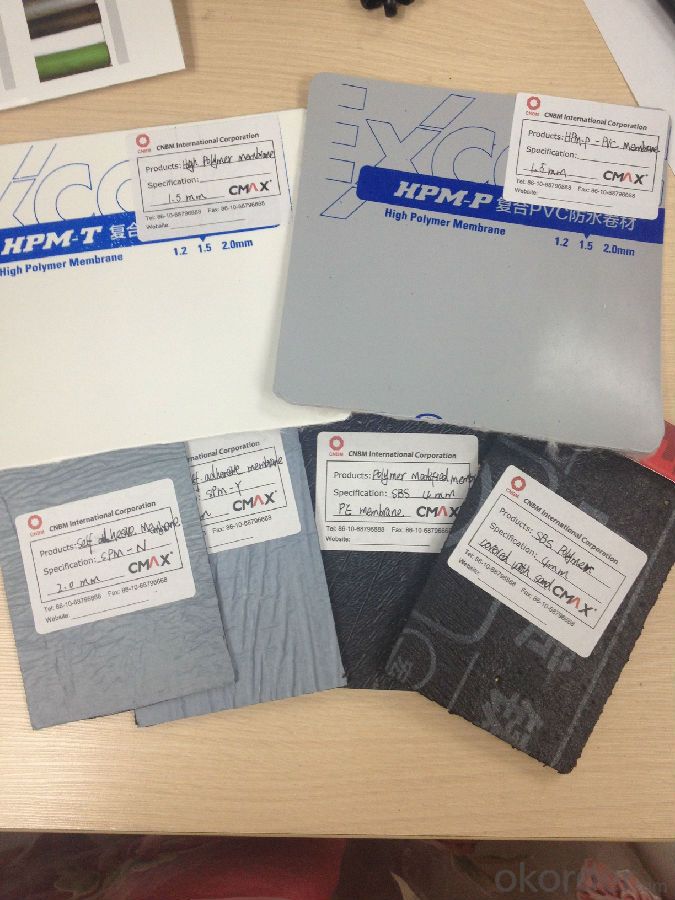

Surface film: PE, SAND, SCHIST,aluminum Thickness: 2.0mm~5.0mm Length: 10.0m

Width: 1.0m Usage: waterproofing for roof, understand,etc

Packaging & DeliveryPackaging Details:

10 sq.m./roll export package or as requirment

Delivery Detail: 15 days after receipt of deposit.

Specifications3mm SBS modified bitumen waterproof membrane

1) 2--5mm

2) Base:PY/G

3) Surface:PE / S / M / Al

Application:

1. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. start application till it is dry.< span="">

2. Application Method:

Heating the bottom surface of membrane and the roof deck surface by flam spray gun or other suitable appliances till the asphalt start to melt(not flowing), then spread. Using roller to compact the membrane so that it can firmly adhere to the base surface. The overlap on the long side should be 100mm and the short side should be 150mm.

·

SBS / APP asphalt waterproof membrane, bituminous waterproof membrane

1. Membranes should be stored under dry and ventilated conditions.

2. Different types of membranes must be piled separately.

3. Under usual condition, storage period is one year since production date.

4. Membrane roll should be put vertically during transportation. It should be kept away

from sunshine and rainwater.

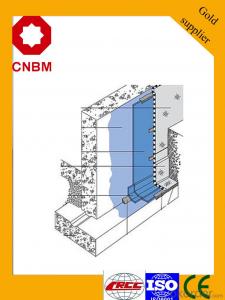

Installation Sketch point

Clean the substrate using broom or high pressure dusty cleaner.

Apply primer

Heat the membrane bottom using a high temperature flame gun.

Push forward while the primer and membrane oil melted

Use a roller to push hard the membrane surface to ensure it stick firmly

1.Base processing: the base surface musts be clean,solid,level,dry;no grit,rift and loosing dust. For a large recess, fill it with cement mortar and then level it. Remove the protrusion and clean dust If working on base slab or lateral face,water lowering should be done.

2.Painting primer before laying the membrane, clean the dust on the surface of concrete base with dust catcher or dust-blower; then paint entirely with treatment agent of DY primer for waterproofing(for purpose of dust consolidation and high adhesive effect).

Why choose us?

1,Honest supplier to the worldwide buyers

2,Factory, direct supplier, competitive price

3,Know how to control the costing with 30 years experience

4,Warm and friendly service and guide

5,China National Standard GB/18242-2008

6,3 shifts workers for 24hrs production, high capacity

7,Small and big orders are welcome from the worldwide

8, 24 hours service for you

FAQ

1,Q:Are you a factory or trading company?

A:We are a factory

2,Q:Where is your factory located?How can i visit there?

A:Our factory is located in Zhengzhou City,Henan Province,China,about 2 hours plane from Shanghai,Guangzhou ect.We can pick you up at the airport.All our clients,from home or abroad,are warmly welcome to visit us!

3,Q:How can i get some samples?

A:We are honored to offer you Free samples.

4:Q:How does your factory do regarding quality control?

A:Quality is priority.King Waterproof Material people always attach great importance to quality controlling from the every beginning to the very end.Our factory has gain ISO9001:2008,ISO4001:2000 ,CEC And LANxess Testing

- Q: Can a waterproofing membrane be used on precast steel surfaces?

- Indeed, precast steel surfaces can benefit from the utilization of a waterproofing membrane. These membranes are specifically engineered to serve as a safeguard against water infiltration, making them suitable for various surfaces, including precast steel. By acting as a waterproof shield, the membrane effectively blocks water from penetrating the surface and causing any potential harm. It is imperative to ensure that the surface is adequately primed and sanitized prior to applying the membrane to ensure optimal adhesion and efficacy. Furthermore, seeking advice from a qualified waterproofing contractor is highly recommended in order to identify the most suitable membrane type and application technique for the specific precast steel surface.

- Q: Is a waterproofing membrane resistant to cracking or shrinking?

- Yes, a waterproofing membrane is designed to be resistant to cracking and shrinking, providing a durable and long-lasting solution for preventing water penetration.

- Q: Can a waterproofing membrane be recycled or disposed of in an environmentally friendly manner?

- Indeed, a waterproofing membrane has the potential to be recycled or disposed of in an environmentally conscious manner. Numerous waterproofing membranes are crafted from recyclable materials like polyethylene or polypropylene, which can be repurposed into new products. The act of recycling these membranes not only diminishes waste, but it also conserves resources and lessens the environmental impact associated with manufacturing fresh materials. In order to recycle a waterproofing membrane, it is crucial to consult local recycling facilities or waste management centers to determine if they accept this specific type of material. Some facilities might have specific guidelines or procedures for recycling membranes, thus adhering to their instructions is of utmost importance. In instances where recycling is not feasible, it is still possible to dispose of the waterproofing membrane in an environmentally friendly manner. Numerous waste management facilities allocate designated areas for construction and demolition waste, providing a proper means of disposing the membrane. These facilities employ methods that minimize the environmental impact of the waste, such as containment and controlled disposal techniques. It is of utmost importance to refrain from tossing the membrane in regular trash or illegally dumping it, as this could harm the environment and contribute to pollution. Proper disposal ensures that any potential pollutants or contaminants within the membrane are appropriately managed, thereby preventing harm to ecosystems and human health. In conclusion, by actively engaging in the recycling or environmentally friendly disposal of a waterproofing membrane, we can contribute to a future that is more sustainable and cleaner.

- Q: How does a waterproofing membrane prevent water penetration?

- A waterproofing membrane prevents water penetration by creating a physical barrier that is impermeable to water. This membrane is usually made of a durable material such as rubber, PVC, or bitumen, which is applied to the surface to be waterproofed. The membrane effectively seals the surface, preventing water from seeping through cracks, joints, or pores. Additionally, the membrane may have additives that enhance its waterproofing properties and ensure long-term protection against water ingress.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oil spills?

- Yes, a waterproofing membrane is generally resistant to hydrocarbons or oil spills.

- Q: Does a waterproofing membrane have any impact on the thermal performance of a structure?

- Yes, a waterproofing membrane can have an impact on the thermal performance of a structure. A waterproofing membrane is typically used in buildings to prevent water infiltration, which can cause damage to the structure over time. By creating a barrier against moisture, the membrane helps to maintain the integrity of the building envelope and protect against potential leaks or water damage. In terms of thermal performance, a waterproofing membrane can help to improve insulation by reducing the amount of heat transfer through the building envelope. By preventing moisture from entering the structure, the membrane also helps to prevent the formation of condensation, which can lead to mold growth and further damage to the building materials. Furthermore, some waterproofing membranes are designed with additional insulation properties, such as foam or reflective coatings, which can further enhance the thermal performance of a structure. These membranes help to reduce thermal bridging and improve energy efficiency by minimizing heat loss or gain through the building envelope. It is important to note that the impact of a waterproofing membrane on the thermal performance of a structure can vary depending on the specific type of membrane, its installation, and the overall design of the building. It is advisable to consult with a professional architect or engineer to determine the most suitable waterproofing solution that meets both the water resistance and thermal performance requirements for a particular structure.

- Q: Can a waterproofing membrane be used on tile surfaces?

- Yes, a waterproofing membrane can be used on tile surfaces. It helps to provide an additional layer of protection against water damage and helps to prevent water penetration through the tile surface and grout lines.

- Q: Can a waterproofing membrane be used on tunnels with vehicular traffic?

- Yes, a waterproofing membrane can be used on tunnels with vehicular traffic. Waterproofing membranes are designed to provide a barrier against water infiltration, protecting the structure from potential damage caused by moisture. In tunnels with vehicular traffic, water can seep through the concrete and cause corrosion, deterioration, and even compromise the structural integrity of the tunnel. By applying a waterproofing membrane, it creates a protective layer that prevents water from penetrating the tunnel walls, roof, and floor. This helps to extend the lifespan of the tunnel and ensures the safety of vehicles passing through. However, it is essential to select a waterproofing membrane specifically designed for heavy traffic conditions to withstand the constant load and wear. Additionally, proper installation and regular maintenance are crucial to ensure the effectiveness and longevity of the waterproofing system in tunnels with vehicular traffic.

- Q: Can a waterproofing membrane be used for roofing applications?

- Yes, a waterproofing membrane can be used for roofing applications. Waterproofing membranes are specially designed to provide a barrier against water penetration and are commonly used in various construction projects, including roofs. These membranes are typically made from materials such as synthetic rubber, thermoplastics, or modified bitumen, which are known for their durability and ability to resist water damage. Installing a waterproofing membrane on the roof can help protect the building from water leaks and moisture infiltration, which can lead to structural damage, mold growth, and other issues. The membrane is typically applied on the roof surface, providing a seamless and watertight layer that prevents water from seeping through the roof. Waterproofing membranes for roofing applications come in various types, such as sheet membranes, liquid or spray-applied membranes, or self-adhering membranes. Each type has its own advantages and suitability depending on the specific roofing requirements and construction conditions. In summary, a waterproofing membrane can indeed be used for roofing applications and is an effective solution to ensure a watertight and durable roof system.

- Q: Can a waterproofing membrane be used in commercial buildings?

- Yes, a waterproofing membrane can be used in commercial buildings. It is commonly used as a protective barrier to prevent water infiltration in various areas such as basements, roofs, and foundations. The membrane acts as a reliable solution to ensure the longevity and structural integrity of commercial buildings, protecting them from potential water damage and leaks.

Send your message to us

Torch Applied Concrete Roof Modified Bitumen SBS Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords