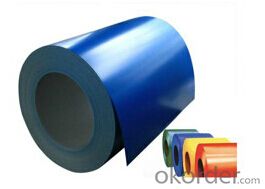

Top Quality Prepainted Steel Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Surface Treatment:Galvanized /Galvalume

Technique:Color Coated

Standard:JIS, GB, ASTM

Steel Grade:Dx51d+Z, SGCC

Product:Prepainted Steel Coil

Color:as Ral or Customer′s Request

Export Markets:Global

Additional Info.

Packing:Standard Export Packing

Origin:China

Production Capacity:10000mts Per Month

Product Description

Prepainted steel coil

Specifications

1.Standard: ASTM,GB,JIS

2.Grade : DX51D+Z

3.Thickness: 0.18-1.5mm

4.Width:914-1250mm

5.Top paint:20mil,Black paint:7mil

6. Technical/Surface treatment: color coated/galvanized/galvalume

7..Useage: widely used in construction,home,appliance,decoration,wear resistant steel,etc.

Advantages:

1. more than 10 years experiences in steel b2usiness

2. good quality

3. competitive price

4. meet your needs via reprocessing

5. excellent service

6. short delivery time

Product :

Packing:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day

- Q: How are steel coils inspected for uniformity using statistical analysis?

- Steel coils are inspected for uniformity using statistical analysis by randomly selecting a sample of coils and measuring specific characteristics such as thickness, width, and weight. These measurements are then analyzed using statistical methods, such as mean, standard deviation, and control charts, to determine if the coils meet the desired uniformity criteria. This approach allows for efficient and reliable assessment of the overall quality and consistency of steel coils.

- Q: What is the minimum thickness of a steel coil?

- The specific grade and type of steel being used, along with the manufacturing process, can cause the minimum thickness of a steel coil to vary. Generally, a steel coil is typically about 0.001 inches (0.0254 millimeters) thick. It is worth mentioning that this value is a general rule and may change depending on the industry's or application's specific requirements and standards.

- Q: Can steel coils be coated with organic materials?

- Yes, steel coils can be coated with organic materials. Organic coatings such as paints, polymers, or other protective substances can be applied to steel coils to enhance their appearance, provide corrosion resistance, or offer other desired properties.

- Q: How are steel coils used in the production of construction materials?

- Steel coils are commonly used in the production of construction materials due to their strength, durability, and versatility. These coils are typically made from high-quality steel and are formed into a continuous, cylindrical shape. In the production of construction materials, steel coils are used in various ways. One primary application is in the manufacturing of steel beams, which are essential components in the construction of buildings, bridges, and other structures. Steel coils are processed and shaped into the desired size and dimension, allowing them to be easily formed into beams that can withstand heavy loads and provide structural support. Another important use of steel coils in construction materials is in the production of roofing materials. These coils are often transformed into corrugated sheets, which are widely used as roofing panels. The durability and weather resistance of steel make it an ideal choice for protecting buildings from the elements, including rain, snow, and strong winds. Additionally, these steel coils can be coated with protective layers to enhance their longevity and prevent corrosion. Steel coils are also employed in the production of construction materials such as pipes, tubes, and poles. These coils are formed into the desired shape and size, allowing for the creation of strong and reliable components for infrastructure projects. Whether it is for underground pipelines, structural support systems, or utility poles, steel coils provide the necessary strength and durability required for these construction materials. Furthermore, steel coils play a crucial role in the production of construction materials used in the fabrication of various fixtures and fittings. From door frames and window frames to reinforcement bars and wire mesh, steel coils are processed and shaped to meet specific requirements. This versatility allows for the creation of a wide range of construction materials that are essential for the completion of buildings and infrastructure projects. In conclusion, steel coils are extensively used in the production of construction materials due to their strength, durability, and versatility. From steel beams and roofing materials to pipes and fixtures, these coils are transformed into various shapes and sizes to meet the specific needs of construction projects. The use of steel coils ensures that construction materials are strong, reliable, and capable of withstanding the demands of the built environment.

- Q: I want to make a lap steel guitar in my wood tech class. can anyone give me a link to a video or site that has steps on how to build one.

- Steel guitars have cables attached to foot pedals to change the sound. I don't know how this would work with the top resting on your lap.

- Q: What are the common coil loading and unloading techniques?

- Some common coil loading and unloading techniques include using overhead cranes or forklifts to lift and move the coils, using coil cars or transfer tables to transport coils within a facility, utilizing coil hooks or C-hooks to securely hold and transport coils, and employing coil tilters or turnstiles to rotate or position coils for loading or unloading.

- Q: So, I'm doing this project for my chemistry class and I need to explain the raw materials in which paper slips are made of. I'm not really sure if galvanized steel is. If not, can someone PLEASE tell me what raw materials are metal paper clips made of???

- As a specially coated type of steel, galvanized metal enjoys a great reputation as being an ideal building product to use for any type of structure that is expected to stand for many years. Here are some basics about how galvanized steel is created, as well as how it can be used in various building projects. Galvanized metal is simply steel in some form that has received a thin coating of zinc oxide. The purpose of the zinc is to protect the steel from elements that normally would lead to oxidation, corrosion and the eventual weakening of the steel. In this sense, the zinc coating acts as what is called a sacrificial anode. In other words, the zinc will protect the steel from corrosion by acting as a barrier between the steel and the corrosive agent, at least until the zinc coating has been completely oxidized. Galvanized metal can be made into supports, girders and even into sheets of metal that can be used in all sorts of construction and building projects.

- Q: What are the applications of steel coils in the aerospace industry?

- The aerospace industry relies heavily on steel coils for various purposes. One important application is in the manufacturing of aircraft structures. Steel coils are commonly used to fabricate wing spars, fuselage frames, and landing gear, as they possess high strength and durability necessary to withstand heavy loads and extreme conditions. Another significant use of steel coils in the aerospace industry is in the production of engine components, specifically turbine blades. These blades experience high temperatures and rotational forces, making it crucial to utilize steel coils due to their excellent heat resistance and mechanical properties. This ensures the reliability and performance of aircraft engines. Steel coils also find utilization in the production of fasteners and connectors necessary for securely joining different parts of an aircraft. Bolts, nuts, and rivets made from steel coils are essential for maintaining the structural integrity and safety of the aircraft. These fasteners need to possess high tensile strength and corrosion resistance. Furthermore, steel coils are employed in the production of fuel tanks and hydraulic systems. The weldability and formability of steel allow for the efficient fabrication of these complex structures. Steel coils can be shaped into various sizes and configurations, providing flexibility in designing fuel tanks and hydraulic components that meet specific requirements. In conclusion, steel coils are indispensable in the aerospace industry. Their use in aircraft structures, engine components, fasteners, and fuel tanks highlights their versatility and reliability. The exceptional strength, durability, heat resistance, and formability of steel make it the preferred material for various aerospace applications, ultimately ensuring the safety and performance of aircraft.

- Q: What are the common methods of welding steel coils?

- The common methods of welding steel coils include arc welding, resistance welding, and laser welding.

- Q: Its big and expensive and i don't know if it would have a logical purpose but its sharp as hell and awesome. Anyways, its made from surgical steel and all i have found on the internet is that its probably 316L (w/e that means). I have another knife made from 440 stainless steel and as far as i know that is pretty much the hardest stainless metal. So why would the more expensive one be made from surgical steel?

- Surgical Steel Knives

Send your message to us

Top Quality Prepainted Steel Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords