Tool Steel D6 Steel Plate, Forging Flat Steel 1.2436 Flat Bar, Forged Tool Steel D6 Steel Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 26 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

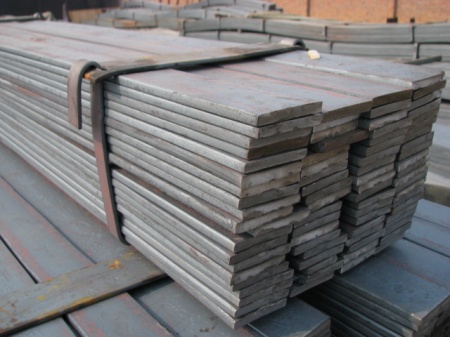

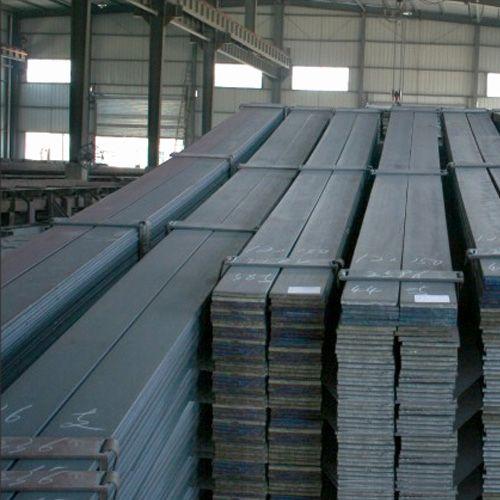

Tool Steel D6 Steel Plate,1.2436 Flat Bar, Forged D6 Steel Bars

Delivery stock within 7 days

ISO9001&BV factory

Flexible MOQ

Tool Steel D6 Steel Plate, Forging Flat Steel 1.2436 Flat Bar, Forged Steel D6 Steel Bars

JC Cold work tool steel products

Specifications

Tool Steel D6 Steel Plate, Forging Flat Steel 1.2436 Flat Bar, Forged Steel D6 Steel Bars

Prompt delivery stock within 7days

MTC DIN10204 3.1/3.2

ISO9001 certified

Flexible MOQ

Equivalent grades

| GB | DIN | AISI |

| Cr12W | 1.2436 | D6 |

Chemical Composition

| C | Si | Mn | Cr | P | S | W |

| 2.06-2.36 | 0.10-0.40 | 0.15-0.45 | 11.0-12.0 | ≤0.03 | ≤0.03 | 0.60-0.80 |

Available sizes

| AISI D6 round steel bar dia 60-800mm | |||||||||

| ASI D6 flat steel bar 25-400mm*200-800mm |

Surface condition

| Black surface/ Grinded/ Machined |

Hardness

| Annealed HB255MAX |

Characteristics

Tool Steel D6/ 1.2436 has: Dry hardening,have upper hot intensity and rigidity, under middle pemperature; |

Applications

| Forged Tool Steel D6, Rolled Tool Steel D6 is used in cutting and drawing tools of high wear resistance, rolls with high dimensional stability, deep drawing tools, tools of wire, bar and tube production, cold shear blades for thin sheets |

Heat treatment

| Annealing temperature: 860-880°C Constant temperature cooling Annealing hardness: ≤255 HB Quenching temperature: 950-1000°C Cooling in air or in oil if large parts. Tempering hardness: ≥60HRC |

16:40:34

- Q: Can steel flat bars be used for making HVAC systems or components?

- Yes, steel flat bars can be used for making HVAC systems or components. Steel is a common material used in the HVAC industry due to its strength, durability, and resistance to corrosion. Steel flat bars can be fabricated and shaped to create various components such as support brackets, frames, or ductwork for HVAC systems.

- Q: Are steel flat bars suitable for creating industrial equipment or machinery?

- Yes, steel flat bars are suitable for creating industrial equipment or machinery. Steel flat bars are known for their strength, durability, and resistance to wear and tear, making them an ideal choice for heavy-duty applications in various industries. They can be easily fabricated, welded, and manipulated to create different components, structures, or frameworks required in industrial equipment or machinery. Additionally, steel flat bars offer excellent load-bearing capabilities and can withstand high levels of stress, making them reliable for supporting heavy loads or providing structural stability. Overall, steel flat bars are widely used in the manufacturing of industrial equipment or machinery due to their favorable mechanical properties and ability to withstand harsh working conditions.

- Q: How do steel flat bars contribute to the overall safety of structures?

- Steel flat bars contribute to the overall safety of structures in several ways. Firstly, steel is an incredibly strong and durable material, making it suitable for withstanding heavy loads and resisting bending or warping. This strength and resilience of steel flat bars provide stability and structural integrity to buildings, bridges, and other structures. They help distribute the weight evenly and prevent excessive deflection, ensuring that structures remain safe and secure. Additionally, steel flat bars are commonly used in construction to reinforce concrete structures. By embedding steel bars within the concrete, a composite material is created that is stronger and more resistant to cracking and breaking under pressure. This reinforcement not only enhances the structural integrity of the building but also increases its resistance to natural disasters such as earthquakes or high winds. Moreover, steel flat bars are often utilized in framing systems, such as in the construction of walls, roofs, and floors. These bars act as load-bearing members by providing support and distributing the weight of the structure. This helps to prevent the collapse of the building and ensures its stability and safety, especially in areas prone to seismic activity or extreme weather conditions. Furthermore, steel flat bars offer fire resistance, which is crucial for the safety of structures. Steel is non-combustible and does not contribute to the spread of fire. It maintains its structural strength even at high temperatures, allowing occupants to evacuate safely and providing firefighters with a stable structure to work from during rescue operations. Lastly, steel flat bars are highly resistant to corrosion, which increases the lifespan of structures. Corrosion weakens the structural integrity of materials, potentially compromising the safety of the building. Steel's resistance to corrosion reduces the risk of structural failure due to rust and deterioration, ensuring the long-term safety of the structure. In conclusion, steel flat bars contribute significantly to the overall safety of structures by providing strength, stability, reinforcement, fire resistance, and corrosion resistance. Their use in construction helps prevent collapse, withstand heavy loads, resist natural disasters, and ensure the safety of occupants.

- Q: Can steel flat bars be used for shelving or storage systems?

- Yes, steel flat bars can be used for shelving or storage systems. Steel flat bars are strong and durable, making them a suitable choice for supporting heavy loads on shelves or in storage units. They can be easily cut and welded to create custom shelving configurations and can withstand the weight of various items. Additionally, steel flat bars have a sleek and modern appearance, making them a popular choice for industrial or contemporary storage systems.

- Q: Are steel flat bars commonly used in the renewable energy sector?

- Yes, steel flat bars are commonly used in the renewable energy sector. They are often used for various applications such as structural support, framing, and mounting systems for solar panels and wind turbines. Steel flat bars are valued for their strength, durability, and versatility, making them an ideal choice for renewable energy infrastructure projects.

- Q: Can steel flat bars be used for making automotive frames or chassis?

- Steel flat bars are suitable for the construction of automotive frames and chassis. This is because steel is known for its strength and durability, making it a popular choice for such applications. These flat bars, which have a rectangular shape, can be used as structural components in the construction process. They can be connected by welding or bolting to achieve the desired shape and size, offering excellent load-bearing capabilities and stability. Moreover, steel flat bars have good resistance to impact and fatigue, allowing them to withstand different driving conditions and stresses. In addition to their performance benefits, steel is easily accessible and cost-effective, making it a practical option for automotive manufacturers.

- Q: What are the benefits of using steel flat bars in architectural projects?

- There are several benefits of using steel flat bars in architectural projects. Firstly, steel flat bars offer high tensile strength and exceptional durability, making them suitable for supporting heavy loads and withstanding harsh weather conditions. Secondly, their versatility allows for various applications such as framing, support structures, and decorative elements. Additionally, steel flat bars are malleable, making it easier to shape and customize according to specific project requirements. Moreover, steel's corrosion resistance minimizes the need for regular maintenance and ensures long-term performance. Lastly, steel is a sustainable and environmentally friendly material, as it can be recycled indefinitely without losing its properties, reducing the overall environmental impact of architectural projects.

- Q: Can steel flat bars be used in the construction of staircases or handrails?

- Certainly, staircases or handrails in construction can definitely utilize steel flat bars. Steel is a material highly regarded for its durability and versatility within the construction industry. It boasts a remarkable strength-to-weight ratio, making it perfect for supporting heavy loads and ensuring structural stability. The shaping and welding of steel flat bars enable the creation of essential components required for staircases and handrails. They serve as stringers, the primary structural supports for staircases, or as balusters, the vertical posts supporting the handrail. Moreover, steel flat bars can also act as the handrail itself, providing a secure grip for users. Moreover, steel flat bars can be easily tailored to meet specific design requirements. They can be cut to desired lengths, drilled to accommodate hardware attachments, and finished with various coatings to enhance aesthetics and safeguard against corrosion. This flexibility makes steel flat bars an excellent choice for constructing staircases and handrails that align with any architectural style or design preference. Overall, steel flat bars are a dependable and long-lasting option for constructing staircases and handrails. Their strength, stability, and versatility have made them a popular choice for both residential and commercial projects.

- Q: Can steel flat bars be bent without breaking?

- Steel flat bars can indeed be bent without breaking. However, the ability of steel to withstand bending without breaking depends on several factors, including the thickness and grade of the steel, as well as the bending technique employed. Commonly, steel flat bars are bent using either cold bending or hot bending methods. Cold bending is typically employed for thin and malleable steel bars and is performed at room temperature. On the other hand, hot bending may be necessary for thicker or harder steel bars. This technique involves heating the steel to a high temperature and bending it while it is still hot. By carefully controlling the bending process and ensuring that the steel does not surpass its elastic limit, it becomes possible to bend steel flat bars without causing them to fracture.

- Q: Can steel flat bars be used in the manufacturing of agricultural machinery?

- Yes, steel flat bars can be used in the manufacturing of agricultural machinery. Steel flat bars offer high strength and durability, making them suitable for various components and structures in agricultural machinery such as frames, brackets, and supports. They can withstand heavy loads, provide stability, and withstand harsh environmental conditions commonly encountered in agricultural operations. Additionally, steel flat bars can be easily fabricated, welded, and machined to meet specific design requirements, making them a versatile choice for manufacturing agricultural machinery.

Send your message to us

Tool Steel D6 Steel Plate, Forging Flat Steel 1.2436 Flat Bar, Forged Tool Steel D6 Steel Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 26 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords