Steel Flat Bar Supply 440C Stainless Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Flat Bar Supply 440C Stainless Flat Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Flat Bar Supply 440C Stainless Flat Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar Supply 440C Stainless Flat Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Commodity: Mild Steel Flat Bar

Standard: GB;JIS

Material: Q195-235;SS400

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Chemical composition of Q235

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 |

B |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045 |

≤0.3 |

Packaging & Delivery of Hot Rolled Flat Bar Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

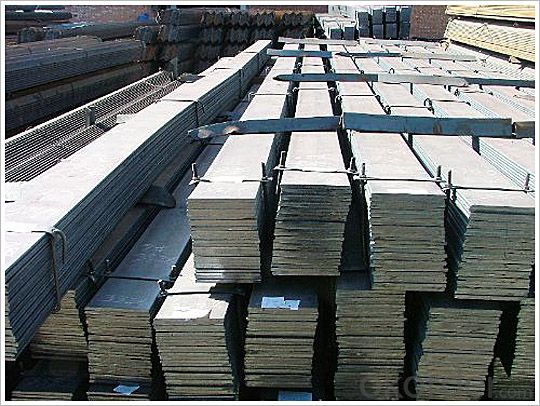

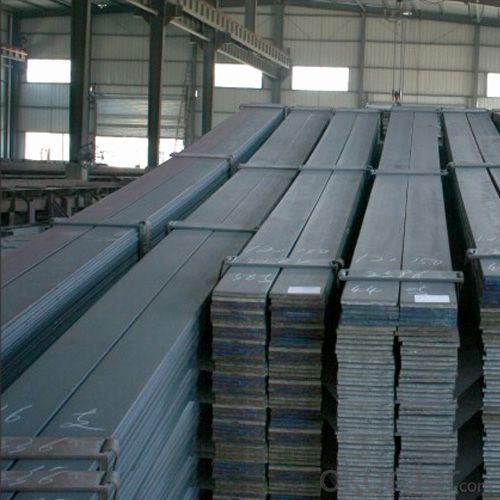

Images:

- Q: Are steel flat bars commonly used in the furniture industry?

- Steel flat bars are widely utilized in the furniture industry due to their versatility and durability, which renders them an excellent option for constructing diverse furniture pieces. Commonly employed as structural supports or legs for tables, chairs, and other furniture items, these bars offer stability and strength, ensuring the furniture's ability to endure weight and frequent use. Moreover, furniture manufacturers and designers favor steel flat bars due to their ease of welding, drilling, and shaping to meet specific design specifications.

- Q: Are steel flat bars suitable for the construction of cultural or arts venues?

- Yes, steel flat bars are suitable for the construction of cultural or arts venues. Steel is a versatile and durable material that can be used in a variety of architectural applications. It offers several advantages that make it an ideal choice for cultural or arts venues. Firstly, steel flat bars provide excellent structural support. They have high tensile strength and can withstand heavy loads, making them suitable for constructing large and complex structures such as theaters, concert halls, or art galleries. Steel's strength-to-weight ratio is also advantageous, allowing for the creation of spacious and open designs without compromising on stability. Additionally, steel flat bars offer design flexibility. They can be easily shaped, bent, or welded to create intricate and artistic structures. This allows architects and designers to incorporate unique and visually appealing elements into their designs, enhancing the aesthetic appeal of cultural or arts venues. Moreover, steel is a sustainable building material. It is highly recyclable, and its production process consumes less energy compared to other construction materials. This makes steel flat bars an environmentally friendly choice, aligning with the growing emphasis on sustainable construction practices. Furthermore, steel's durability ensures that cultural or arts venues constructed with steel flat bars will have a long lifespan. Steel is resistant to corrosion, fire, and pests, reducing maintenance and repair costs over time. This durability makes it a reliable choice for venues that are expected to withstand heavy foot traffic and frequent usage. In conclusion, steel flat bars are indeed suitable for the construction of cultural or arts venues. Their strength, design flexibility, sustainability, and durability make them a popular choice among architects and developers. By utilizing steel, cultural or arts venues can be built to withstand the demands of artistic performances and exhibitions while also providing aesthetically pleasing and sustainable spaces for the public to enjoy.

- Q: Can steel flat bars be used for fencing or gates?

- Certainly! Fencing or gating purposes can indeed make use of steel flat bars. These bars possess qualities such as strength, durability, and resistance to corrosion, rendering them ideal for outdoor applications. By welding or bolting them together, a robust fence or gate structure can be formed. Moreover, steel flat bars can be conveniently tailored and molded to meet specific design specifications. Irrespective of whether it is intended for residential, commercial, or industrial usage, steel flat bars offer a dependable and enduring solution for fencing or gating requirements.

- Q: Are steel flat bars suitable for bridges?

- Certainly! Bridges can be constructed using steel flat bars because they possess qualities that make them ideal for this purpose. Steel is a commonly preferred material in bridge construction because it offers a high strength-to-weight ratio, durability, and the ability to withstand heavy loads. Steel flat bars, specifically, provide numerous advantages for the construction of bridges. They offer excellent support and stability, particularly when utilized as structural components or reinforcement in concrete bridge decks. Additionally, steel flat bars can be easily fabricated, cut, and welded to meet the specific design requirements of a bridge. This makes them a versatile choice for bridge construction. Moreover, steel flat bars have a lengthy lifespan and require minimal maintenance, which is crucial for ensuring the bridge's longevity and safety. All in all, steel flat bars are a suitable and extensively used material in bridge construction due to their strength, durability, versatility, and ease of maintenance.

- Q: Can steel flat bars be used for manufacturing kitchen equipment or appliances?

- Kitchen equipment or appliances can indeed be manufactured using steel flat bars. Steel is widely used in the manufacturing industry due to its versatility and durability. It possesses excellent strength and resistance to corrosion, which makes it suitable for kitchen equipment exposed to moisture and high temperatures. By shaping, welding, and forming steel flat bars, various components and structures can be created, making them perfect for constructing kitchen appliances like cabinets, countertops, shelving, and even utensils. Furthermore, steel is easy to clean and maintain, making it a practical option for kitchen equipment that requires high hygiene standards. In conclusion, steel flat bars are a dependable and popular choice for manufacturing kitchen equipment and appliances due to their strength, durability, and versatility.

- Q: Can steel flat bars be used in the manufacturing of machinery parts?

- Yes, steel flat bars can be used in the manufacturing of machinery parts. They are commonly utilized for their strength, durability, and versatility, making them suitable for various applications in machinery manufacturing processes.

- Q: What are the weight and load-bearing capacities of different steel flat bar sizes?

- The weight and load-bearing capacities of steel flat bars can vary depending on their size. Generally, the larger the size of the flat bar, the higher its weight and load-bearing capacity. Here are some common steel flat bar sizes and their approximate weight and load-bearing capacities: 1. 1/8 inch thick steel flat bar: This is a relatively thin flat bar and is typically used for lighter applications. Its weight and load-bearing capacity can range from around 0.42 pounds per foot and 200 pounds per foot respectively. 2. 1/4 inch thick steel flat bar: This size is slightly thicker and can handle heavier loads. It typically weighs around 0.85 pounds per foot and has a load-bearing capacity of approximately 400 pounds per foot. 3. 3/8 inch thick steel flat bar: This size is even thicker and can support even greater loads. Its weight and load-bearing capacity can range from around 1.27 pounds per foot and 600 pounds per foot respectively. 4. 1/2 inch thick steel flat bar: This is a significantly thicker flat bar and is commonly used for heavy-duty applications. It weighs approximately 1.7 pounds per foot and has a load-bearing capacity of around 800 pounds per foot. 5. 1 inch thick steel flat bar: This is a very thick flat bar suitable for extremely heavy loads. It typically weighs around 3.4 pounds per foot and has a load-bearing capacity of approximately 1600 pounds per foot. It is important to note that these weight and load-bearing capacities are approximate values and can vary based on the specific grade and quality of the steel used. Additionally, other factors such as the length and support conditions of the flat bar should also be taken into consideration when determining its maximum load-bearing capacity. It is recommended to consult professional engineers or reference load tables provided by steel manufacturers for accurate and specific information on weight and load-bearing capacities of steel flat bars.

- Q: What industries commonly use steel flat bars?

- Steel flat bars are commonly used in a wide range of industries due to their versatile nature and durability. Some of the industries that commonly use steel flat bars include construction, manufacturing, automotive, infrastructure, and engineering. In the construction industry, steel flat bars are used for various purposes such as support beams, frames, braces, and structural components in buildings and bridges. They provide strength and stability to structures, making them ideal for withstanding heavy loads and pressure. Manufacturing industries also rely on steel flat bars for fabricating machinery, equipment, and tools. Due to their malleability, steel flat bars can be easily shaped and machined to meet specific requirements, making them suitable for various manufacturing processes. The automotive industry utilizes steel flat bars in the production of vehicles, especially in the chassis and body frames. Steel flat bars provide the necessary strength and rigidity to withstand the stresses and strains experienced by automobiles, ensuring safety and durability. Infrastructure projects such as highways, railways, and airports also extensively use steel flat bars. These bars are used in the construction of beams, columns, and other structural elements, providing the necessary strength to support heavy loads and withstand environmental conditions. Engineering industries also heavily rely on steel flat bars for a wide range of applications. These bars are commonly used in the fabrication of machinery, equipment, and components that require strength, resilience, and versatility. They are also used in the construction of support structures, frames, and braces required in various engineering projects. In summary, the industries that commonly use steel flat bars include construction, manufacturing, automotive, infrastructure, and engineering. Their versatility, strength, and durability make them indispensable in these industries for various applications and projects.

- Q: What are the different types of corners available for steel flat bars?

- Steel flat bars typically have two types of corners: square corners and rounded corners. 1. Square corners, which are the most common type, have a 90-degree angle. They give a clean and sharp look and are often chosen when a precise and angular appearance is desired. They are also easy to fit and join with other materials, making them versatile for various uses. 2. On the other hand, some steel flat bars come with rounded corners. These corners have a smooth curve instead of a sharp angle, resulting in a more streamlined and visually pleasing look. Rounded corners are often preferred for safety reasons as they eliminate potential sharp edges that could cause injuries. They are commonly used in architectural and decorative applications where a softer and more visually appealing design is desired. When selecting the appropriate type of corner for your steel flat bars, consider the specific requirements of your project. Factors such as the intended application, safety considerations, design preferences, and ease of installation should be taken into account.

- Q: What is the bending capacity of a steel flat bar?

- The ability of a steel flat bar to withstand bending forces without breaking or permanently deforming is known as its bending capacity. Several factors, including the steel's dimensions, thickness, composition, the applied load, and the type of bending being performed, influence the bending capacity. Steel flat bars generally have a high bending capacity due to their inherent strength and durability. To determine the specific bending capacity of a steel flat bar, engineers can calculate the maximum bending moment it can withstand before failure occurs. This calculation involves using engineering formulas and principles like the moment of inertia and the steel's yield strength. It should be noted that the bending capacity of a steel flat bar can vary depending on its grade or alloy. Different grades of steel have distinct mechanical properties, such as tensile strength and yield strength, which directly affect their bending capacity. Therefore, considering the specific grade and composition of the steel flat bar is crucial when assessing its bending capacity. Furthermore, the shape and dimensions of the steel flat bar also significantly impact its bending capacity. Wider and thicker flat bars generally have higher bending capacities compared to narrower and thinner ones. This is because the increased cross-sectional area provides more resistance against bending forces. In conclusion, the bending capacity of a steel flat bar is influenced by factors like the grade of steel, dimensions, and applied load. To accurately determine the bending capacity, consulting engineering references or professionals who can perform calculations based on the specific properties of the steel flat bar is recommended.

Send your message to us

Steel Flat Bar Supply 440C Stainless Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords