Bulb Flat Steel A,B,D,E,AH32 for Shipbuilding Bulb Flats

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Bulb Flat Steel A,B,D,E,AH32 for Shipbuilding Bulb Flats at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Bulb Flat Steel A,B,D,E,AH32 for Shipbuilding Bulb Flats are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Bulb Flat Steel A,B,D,E,AH32 for Shipbuilding Bulb Flats in Coils are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1.DIN1.2311 flat steel China

2.16-900*185-2300*3000-5800MM or as your requests

3.HRC=28--34

4.Top 10 supplier in Guangdong CN

Round | Diameter | Length | |

20mm-600mm | 2000mm-5800mm | ||

Steel plate | Thickness | Width | Length |

20-400mm | 185-2200mm | 3000mm-5800mm | |

Chinese | American | German | Swedish | Japanese |

GB | AISI | DIN | ASSAB | JIS |

3Cr2Mo | P20 | 1.2311 | 618 | PDS-3 |

Degree of hardness and the metallography structure are even, the cutting value and the polishing performance are outstanding, can be harden by flame, plates hardly chrome and nitriding. This mould steel can apply to general requirements of the size of the plastic mould and can be operated by electric corrosion.

We are direct die steel manufacturer, we can supply kinds of die steel bars with the competitive price and high-quality service, we incerely provide high quality and favorite price, we are looking forward to establish the mutual beneficial and long- term relation with free to contact us for future information!

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

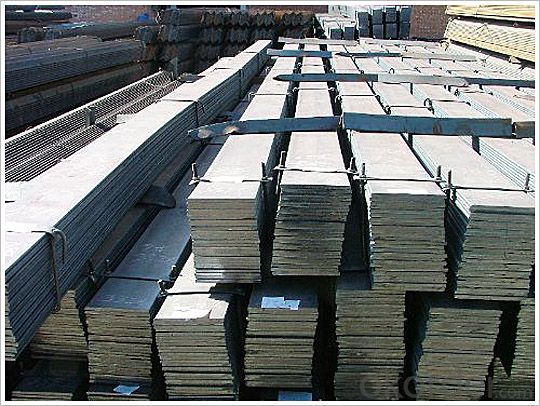

Images:

- Q: Can steel flat bars be polished or buffed?

- Indeed, it is possible to polish or buff steel flat bars. Polishing or buffing entails utilizing abrasive materials to eliminate any flaws or marks present on the steel's surface. This technique aids in augmenting the aesthetic appeal of the steel flat bars, bestowing upon them a sleek and glossy appearance. Moreover, polishing or buffing also contributes to enhancing the steel's resistance against corrosion by eradicating any impurities or oxidation on its surface.

- Q: Do steel flat bars have a specific tolerance range?

- Yes, steel flat bars have a specific tolerance range. The tolerance range for steel flat bars is typically specified by industry standards or customer requirements to ensure consistent dimensions and quality.

- Q: What is the maximum thickness-to-width ratio for a steel flat bar?

- Several factors, including the specific steel grade, intended usage, and industry standards, influence the maximum thickness-to-width ratio for a steel flat bar. Generally, the maximum ratio is typically 1:10, meaning that the thickness of the flat bar should not surpass 10 times its width. If this ratio is surpassed, it can result in potential problems such as compromised structural integrity, heightened susceptibility to bending or warping, and challenges in fabrication or handling. Therefore, it is crucial to consider the specific application and refer to relevant industry guidelines or standards to determine the appropriate thickness-to-width ratio for a steel flat bar in a given scenario.

- Q: What are the different grades of steel used in flat bars?

- Flat bars commonly use several grades of steel, each with unique properties and applications. Some of the most frequently used grades are: 1. Mild Steel (or low carbon steel): This grade is widely utilized in flat bars due to its low carbon content, making it easy to work with and weldable. It finds applications in construction, automotive, and general fabrication. 2. Carbon Steel: With a higher carbon content (usually ranging from 0.30% to 2.0%), carbon steel offers increased strength and hardness compared to mild steel. It is suitable for applications requiring higher load-bearing capabilities, such as machinery parts and structural components. 3. Alloy Steel: This type of steel contains additional elements like manganese, silicon, nickel, chromium, or molybdenum, which enhance mechanical properties such as strength, hardness, and corrosion resistance. Alloy steel flat bars are commonly used in manufacturing tools, gears, and machine parts. 4. Stainless Steel: Stainless steel is corrosion-resistant and contains a minimum of 10.5% chromium. It excels in environments prone to rust, staining, and corrosion, making it ideal for applications in food processing, pharmaceuticals, and marine industries. Stainless steel flat bars come in various grades, with 304 and 316 being the most common. 5. Tool Steel: Designed to exhibit exceptional hardness, toughness, and wear resistance, tool steel is specialized for manufacturing cutting tools, molds, and dies. Tool steel flat bars are available in grades like A2, D2, and O1, each offering specific properties for different applications. These examples represent only a few of the many specialized grades available for flat bars, including heat-resistant steel, wear-resistant steel, and high-strength steel. The choice of grade depends on specific application requirements, such as strength, corrosion resistance, hardness, and other properties.

- Q: Can steel flat bars be used for making window frames or door frames?

- Window frames or door frames can indeed be made using steel flat bars. Steel flat bars possess remarkable strength, durability, and exceptional structural properties, rendering them an optimal selection for frame construction. They furnish windows or doors with stability and support, guaranteeing their enduring functionality. Moreover, steel flat bars can be effortlessly welded, cut, and molded to accommodate precise measurements and designs, presenting opportunities for customization and adaptability in frame assembly. All in all, steel flat bars represent a dependable and pragmatic material for fabricating window frames or door frames.

- Q: Are steel flat bars available in customized lengths?

- Yes, steel flat bars are available in customized lengths. Steel suppliers and manufacturers typically offer a range of standard lengths for flat bars, but they also have the capability to cut and customize the bars to specific lengths as per customer requirements. This flexibility allows customers to order steel flat bars in the exact lengths they need for their specific projects or applications, ensuring a perfect fit and minimizing waste. Whether it's a small DIY project or a large-scale construction project, customers can typically work with steel suppliers to obtain customized lengths of steel flat bars to suit their needs.

- Q: What are steel flat bars?

- Steel flat bars are long and rectangular pieces of steel that have a flat surface and straight edges. They are commonly used in construction, manufacturing, and fabrication industries for various applications such as supports, braces, framework, and reinforcement due to their strength and versatility.

- Q: What is the thickness tolerance for steel flat bars?

- The thickness tolerance for steel flat bars varies depending on the specific manufacturing standards and requirements. Generally, the tolerance can range from +/- 0.005 to +/- 0.030 inches, but it is important to consult the specific standard or specification for accurate information.

- Q: Are steel flat bars suitable for making storage racks?

- Yes, steel flat bars are suitable for making storage racks. Steel flat bars are known for their strength, durability, and versatility, making them an ideal choice for constructing storage racks. They have a high load-bearing capacity, allowing them to safely hold and support heavy objects. Additionally, steel flat bars are resistant to bending and warping, ensuring the longevity of the storage racks. They are also easy to work with and can be welded or bolted together to create custom-sized racks that meet specific storage needs. Overall, steel flat bars provide a reliable and sturdy framework for storage racks, making them a popular choice in various industries and settings.

- Q: How do steel flat bars contribute to the overall sustainability of infrastructure projects?

- Steel flat bars contribute to the overall sustainability of infrastructure projects in several ways. Firstly, they are durable and long-lasting, which means they require minimal maintenance and replacement over time, reducing the need for additional resources. Secondly, steel is a highly recyclable material, so at the end of its lifespan, flat bars can be recycled and reused in other projects, reducing waste and conserving natural resources. Additionally, steel flat bars have a high strength-to-weight ratio, meaning they can support heavy loads while requiring less material, which helps to reduce the overall carbon footprint of infrastructure projects.

Send your message to us

Bulb Flat Steel A,B,D,E,AH32 for Shipbuilding Bulb Flats

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords