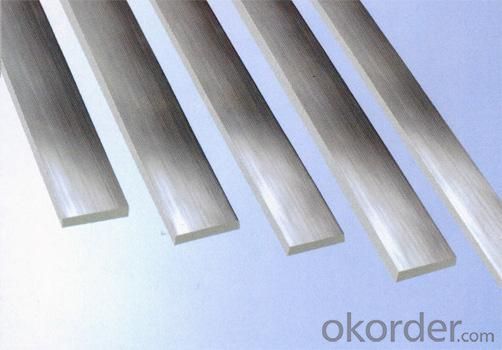

Spring stainless steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering spring stainless steel flat bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Spring stainless steel flat bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel flat bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Spring Steel can be divided into two types. One is carbon spring steel, and other one is alloy spring steel.

Alloy spring steel is based on carbon spring steel, by adding one or more alloying elements to improve the mechanical properties, hardenability and other properties to meet the requirement for manufacturing all kinds of spring steel.

Specification of Spring Steel:

-Material: 70Si2CrA

-Production: Hot rolled or cold rolled

-Standard: GB/T·5218-1999

-Type: Spring Steel

-Alloy or no: Alloy

Mechanical Properties:

-Annealing Condition:

1, Tensile Strength: σb/MPa:≤835

2, Elongation: δ/%:≥8

-Quencher condition:

1, Tensile strength: σb/MPa:785~1175

2, Elongation: -

Usage/Applications of Spring Steel:

For manufacturing all kinds of flat spring or round spring with small sections, clockwork spring,

Packaging & Delivery of Spring Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail:

1, Delivery time: 30~45 working days after receive buyer’s T.T. or L/C.

2, Delivery status should be written in the contract. (Heat treatment or no)

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L. 100% payment before shipment.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L. 100% payment before shipment.

3, Negotiable.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Can steel flat bars be used in the construction of industrial structures?

- Yes, steel flat bars can be used in the construction of industrial structures. Steel flat bars are versatile and strong, making them suitable for a wide range of applications in industrial construction. They are commonly used in the construction of beams, columns, frames, and supports. Steel flat bars offer excellent structural integrity and are able to withstand heavy loads and high-stress conditions. Additionally, they are durable, corrosion-resistant, and require minimal maintenance. The versatility and strength of steel flat bars make them an ideal choice for the construction of industrial structures.

- Q: What are the different methods of surface coloring for steel flat bars?

- There are several different methods of surface coloring for steel flat bars, each with its own unique advantages and applications. Some of the most commonly used methods include: 1. Hot-dip galvanizing: This process involves immersing the steel flat bar into a bath of molten zinc, which creates a protective layer on the surface. Galvanizing provides excellent corrosion resistance and is often used in outdoor or high-moisture environments. 2. Powder coating: Powder coating involves applying a dry powder paint to the surface of the steel flat bar, which is then cured using heat. This method offers a wide range of color options, excellent durability, and resistance to chipping, scratching, and fading. 3. Electroplating: Electroplating is a process where a thin layer of metal, such as chrome or nickel, is deposited onto the steel flat bar's surface using an electric current. This method can enhance the appearance of the steel while also providing corrosion resistance. 4. Paint coating: The traditional method of applying paint directly to the surface of the steel flat bar is still widely used. It allows for a wide variety of colors and finishes, but the durability and corrosion resistance may not be as high as other methods. 5. Chemical coloring: This method involves using chemicals to create a controlled oxidation process on the steel flat bar's surface, resulting in various colors and shades. Chemical coloring can provide an attractive appearance while also increasing corrosion resistance. 6. Anodizing: Anodizing is primarily used for aluminum, but it can also be applied to steel flat bars. It involves creating an oxide layer on the surface through an electrochemical process, resulting in enhanced corrosion resistance and the ability to add color through dyes. Each of these methods has its own set of advantages and considerations, such as cost, environmental impact, durability, and aesthetic appeal. The choice of surface coloring method will depend on the specific requirements of the application, including the desired appearance, level of corrosion resistance, and budget constraints.

- Q: How are steel flat bars measured and specified?

- Steel flat bars are typically measured and specified by their width, thickness, and length. The width refers to the measurement across the bar's broadest side, while the thickness indicates the measurement of the bar's narrowest side. The length specifies the overall size of the bar. These measurements are important for accurately determining the dimensions and specifications of steel flat bars, allowing for proper selection and use in various applications.

- Q: What are the different types of surface defects in steel flat bars?

- There are several different types of surface defects that can occur in steel flat bars. Some of the most common include: 1. Scale: Scale refers to an oxide layer that forms on the surface of the steel during the manufacturing process. It can appear as a flaky or rough substance and can affect the appearance and smoothness of the flat bar. 2. Rust: Rust is a common surface defect in steel flat bars, especially if they have been exposed to moisture or corrosive environments. It appears as a reddish-brown coating on the surface of the steel and can weaken its structural integrity. 3. Pitting: Pitting occurs when small cavities or depressions form on the surface of the flat bar. This defect is typically caused by corrosion or chemical reactions and can lead to reduced strength and durability. 4. Surface cracks: Surface cracks are fractures that appear on the outer layer of the steel flat bar. They can occur due to various factors such as manufacturing defects, improper handling, or excessive stress. Surface cracks can compromise the strength and safety of the flat bar. 5. Lamination: Lamination defects involve the separation of layers or the presence of voids within the steel flat bar. This defect can occur during the manufacturing process or as a result of improper heat treatment. Laminations can weaken the structural integrity of the flat bar and make it more susceptible to failure. 6. Inclusions: Inclusions are foreign particles or impurities that become trapped within the steel during the manufacturing process. They can appear as dark or irregular spots on the surface of the flat bar and can affect its mechanical properties and performance. It is important to identify and address these surface defects in steel flat bars to ensure the quality, reliability, and safety of the final product. Regular inspections, proper handling, and appropriate surface treatment can help prevent and mitigate these defects.

- Q: Can steel flat bars be used in the construction of buildings?

- Yes, steel flat bars can be used in the construction of buildings. Steel flat bars are commonly used in construction due to their strength, durability, and versatility. They provide structural support and are often used for framing, reinforcement, and support systems in buildings. Steel flat bars can be easily cut, welded, and shaped to meet the specific requirements of a construction project. Additionally, they are resistant to corrosion, fire, and pests, making them an ideal choice for long-lasting and sturdy building construction.

- Q: Can steel flat bars be used for making staircases or ramps?

- Yes, steel flat bars can be used for making staircases or ramps. Steel flat bars are commonly used in construction due to their strength and durability. They can provide a sturdy and stable framework for staircases and ramps, ensuring safety and structural integrity.

- Q: How are steel flat bars measured?

- Steel flat bars are typically measured by their width and thickness. The width refers to the horizontal dimension of the bar, while the thickness refers to the vertical dimension. Both measurements are usually expressed in millimeters or inches. For example, a steel flat bar might be specified as 50 mm wide and 5 mm thick. These measurements help to determine the overall size and shape of the bar, allowing it to be accurately used in construction, manufacturing, or other applications.

- Q: What is the cost of a steel flat bar?

- The cost of a steel flat bar can vary depending on various factors such as the size, grade, and quantity needed. It is best to check with local suppliers or online retailers to get an accurate price. Prices can range from a few dollars to several hundred dollars per bar.

- Q: Can steel flat bars be used in the construction of pipelines?

- Yes, steel flat bars can be used in the construction of pipelines. They are commonly utilized for various applications in pipeline construction, such as providing support, reinforcement, and structural integrity. Steel flat bars offer high strength, durability, and resistance to corrosion, making them suitable for withstanding the demands of pipeline environments.

- Q: Are steel flat bars resistant to impact?

- Generally speaking, steel flat bars possess resistance to impact. Steel, renowned for its remarkable tensile strength and durability, can endure substantial force and impact without deformation or fracture. Notably, steel flat bars find wide application in construction, manufacturing, and fabrication, particularly in scenarios necessitating impact resistance. Nevertheless, it is imperative to acknowledge that the impact resistance of steel flat bars may fluctuate based on variables like steel grade, bar thickness, and particular usage conditions.

Send your message to us

Spring stainless steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords