Three Ram BOP of High Quality with API 16A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Three Ram BOP Description

The ram preventer is designed and produced according to API 16A standard with different size of blind rams, pipe rams and shear rams. In order to saving time of replacement gate valve, variable ram designing put into use.

High-grade ram rubber core and side flange sealing can meet the extreme circumstances, such as high and low temperature or acidic conditions.

The housing of BOP is made of low alloy steel forgings or castings. Chemical composition, mechanical properties and forming process conform to the requirements of standards.

2. Main Features of Three Ram BOP

Ram preventers supplied by us are classified as two kinds of structure, Cameron and Shaffer type. The Cameron type preventer changes ram by hydraulic way, which is safe, reliable, and easy to replace the ram.

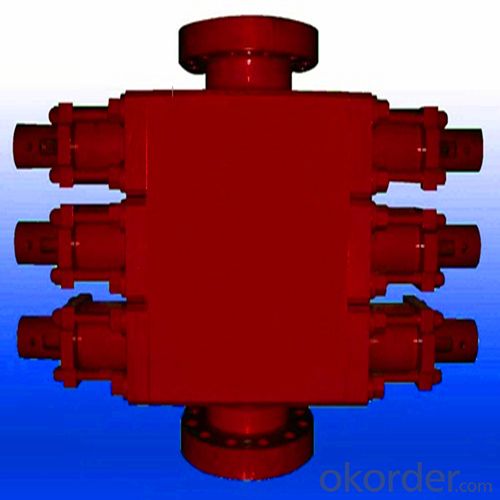

3. Three Ram BOP Images

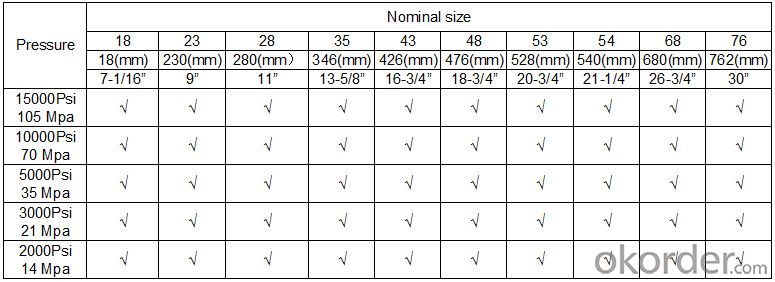

4. Three Ram BOP Specification

5. FAQ of Three Ram BOP

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing Oilfield products in China, mainly offering various of oilfild products consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: A diabetic patient undergone CABG having aortic valve problem.Cardiologist suggested valve replacement

- Can be cured by valve replacement... alternatively, if you can't/won't go through open heart surgery then you may be able to get valvuloplasty. A balloon is used to stretch the valve open. This does not last nearly as long as replacement, but avoids surgery. A third alternative would be to contact one of the percutaneous valve REPLACEMENT centers (Mayo, Cleveland Clinic, Columbia). This is an experimental procedure which replaces the valve using catheters instead of surgery. Advice offered here is not meant to be a replacement for proper evaluation and examination by a qualified medical professional and should not be construed as such.

- Q: It started leaking slowly so I opened the release valve for about 20 secs than closed it back to see if that would help, but now it leaks even more. So I had to shut off the water that's coming into the water heater and know I can't use the hot water in my house. Can someone help me please!!!!

- You have to replace the water pessure valve. If you can remove the old one, Take it with you to any plumbers merchants, and get another one, but make sure it is marked with the same pressure as the one you removed. All water heater makes, have different pressures. Good luck.

- Q: hi im 13 years old and i am having my tricuspid valve repaired or replaced the doctors do know what they are going to do yet.what is the success rate of the operation ?and whats the survival rate of the operation ?all other info would be appreciatedthanksalex

- The okorder /

- Q: I was told on Tuesday that i have mitral valve prolapse and that i inherited it and that i will be fine. Well i take toporol xl 50 mg because the mitral valve prolapse makes my heart beat fast. For the past week i have noticed that my chest/lungs get tight, kind of like i have congestion in my chest, it comes and goes and sometimes its really bad and sometimes i can tolerate it. Is this normal for someone with the mitral valve condition. My cardiologist didn't go into details about the symptoms and i'm wondering if i should go see another doctor. I do have a sniffly nose and was wondering if this could be symptoms of a cold or something else. Any one out their with my condition having the same problems??? If so what is it???

- Haven't had it done before but: It's a pretty involved procedure. Patient is put under general anesthesia and is usually on the cardiopulmonary bypass machine (heart-lung machine) since you can't really replace a heart valve if the heart is beating. mortality for full valve replacement according to wiki is 6-8 percent, prob less than 5% for young healthy patients. Recently, many people have been doing the procedure laparoscopically. Patients are put into the surgical ICU for typically 1-2 days after the surgery. You can be discharged about a week after. Obviously there's risks, this is a very involved and definitely not a simple procedure. However, the cardiothoracic surgeons do these procedures every day for their entire lives-they're very skilled and qualified. good luck!

- Q: I have a 97 Neon. The Canister Purge Valve circuit gives a code 31 stating that it has a problem. I've replaced the valve, which didn't make the code go away. I removed the battery for a few hours, and the code went away. I drove for about 2 weeks and the code came back on. If it's not the valve, where do I look next?

- Could you describe this canister purge valve? Not sure what you are talking about here. Is it part of the emissions, part of the radiator, or what. I am just guessing it's part of the emissions. In which case, I need to know if it has a smog pump. Could be the pump, could be a clogged up cat, could be a bad EGR valve. Need some more info to help beyond this point. Good luck.

- Q: the blow off valve has a hose that goes to the intake. Do you need that hose.

- if you want it to operate properly the yes you will need it. The valves are also adustable but you need a tech manual to and special tool to do it propperly dont just guess at its setting rather know it. I assume the picture i looked at was your engine. Unless you like taking chaces i would recomend you put your timing belt cover back in place. If anything should get in there between your t-belt and gears or pullys the belt could be damaged and if it does get damaged you could damage the valves in the event of t-belt failure. I know people like to see the belt and gears moving and if that is what you are wanting i would suggest installing one of the clear t-belt covers that are available. unfortunatly i do not know who makes them. if you cant find out go to a car show and talk to gear heads that have them on there cars.

- Q: I think they need to be taught how to count. Honesty... Half-Life, Half-Life 2, Half-Life 2: Episode One, Half-Life 2: Episode Two... Where the hell is 3 already?

- I even have an 18 month old that maintains to be on the bottle. She basically makes use of it at nap bedtime inspite of the undeniable fact that. and that i'm interior the skill of weining her off of it thoroughly. I had issues getting my daughter to initially take to a sippy cup too. basically save attempting... perchance permit him p.c.. out a cup on the save. that could get him excited approximately it. My dad and mom are people who have been given my daughter to take a sippy cup. My mom had me deliver my daughter over with basically a cup, no bottles. She used the thought that as quickly as she's thirsty she'll take it. and he or she did. She suggested it took a pair of tries, and a pair cries for her bottle and a tantrum or 2, yet my mom persevered. as quickly as she have been given residing house I did the comparable and (nonetheless a tantrum or 2, yet..) it worked. Bedtimes are yet another tale inspite of the undeniable fact that... nonetheless engaged on that. I even have 2 greater concepts... First attempt applying the sippy cups that have the versatile rubber nipples/tops. Nibby sells some at walmart. they're greater reminiscent of bottles than the hard plastic ones and could make the transaction smoother. and 2d. .. additionally at walmart, they sell nipples for bottles, that reproduction ingesting from a sippy cup. it could help to apply those for a short at the same time as.

- Q: I was told my 1995 chevy needs an idle air control valve. I know my idle is getting rougher so I may need this. What is the function of this valve and what would happen if I don't get it? Will a new valve smooth my idle? Anyone know if this valve is hard to install or not?

- Iac Valve Function

- Q: I been playing the trombone for 6 years, do you think i could learn to play the baritone easily,which baritone is easier,3 valve or 4 valve.

- Some baritones have 3 valves, but the others have 4. The 3 valved ones are baritones and then the 4 valved ones are euphoniums.

- Q: Hello. I am interested in purchasing a Hydroclean Fill Valve for my toilet. Are these good fill valves? Thanks!

- who cares, a toilet fill valve only costs a few bucks. as long as it opens and closes it's a good valve. if it only lasts for a year then it's a piece of junk and you should try another brand. it's not a major decision

Send your message to us

Three Ram BOP of High Quality with API 16A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords