Thin Aluminum Sheets - 10 mm Aluminium Sheet for Industrial/Construction/Decorative

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

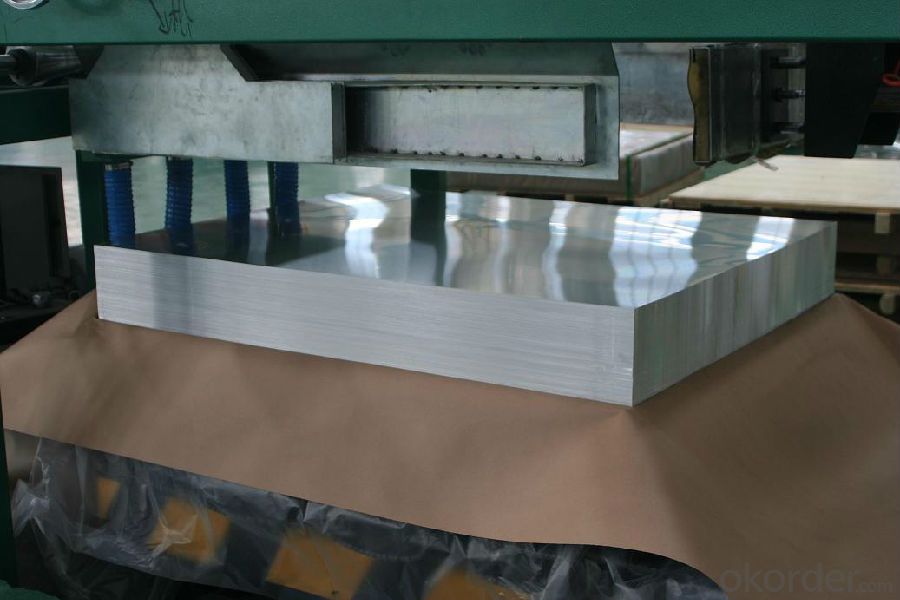

10 mm Aluminium Sheet for Industrial/ Construction/ Decorative

l Product Details

1.Alloy: 1060, 1050, 3003, 5052, 5754, 5083, 5A06, 5A02, 5A03, 5082, etc

2.Temper: O, H14, H24, H16, H18

3.Thickness:0.2-200mm

4.Width:20-2400mm

| Aluminium sheet | |||||

Packing: Export plywood pallets or box. The bundle weight not exceed 2MT. Loading: by 1x20GP can load about 18MT | |||||

| Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

| Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

| Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

| MOQ | 2.5 tons | ||||

| Payment term: | T/T, L/C | ||||

| Kind attention: Specifications can be customized as the customer’s requirements. | |||||

l Packaging & Delivery

Packaging detail: Covering with brown paper and plastic bag then packed with wooden plywood then directly loading into container for transshipment. For the thickness which is more than 1.50mm, one paper interleave into two sheets.

Delivery detail: within 30days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium sheet has always been one of the most popular products in CNBM. With advanced technic skills and equipment, CNBM has produced high quality aluminium sheets that meet international standard.

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Explain the impact of aluminum sheets on the thermal insulation of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can significantly reduce the thermal insulation of a building. They allow heat to transfer easily through them, which can lead to increased heat loss in winter and heat gain in summer. This can result in higher energy consumption for heating and cooling, making the building less energy-efficient. However, when used in combination with proper insulation materials and techniques, aluminum sheets can still be part of an effective building envelope, provided their thermal bridging effects are mitigated.</p>

- Q: as for heating coil and aluminum sheet, which one is better for heating?

- Both of them have advantage. It depends on the new product type it’s applied. Heating coil: it’s applied in some products with high temperature and large heat release, such as oven and other types.

- Q: How do aluminum sheets perform in terms of weldability?

- The weldability of aluminum sheets is generally good because of their low melting point and excellent thermal conductivity. Various techniques, such as TIG welding, MIG welding, or spot welding, can be used to weld aluminum sheets. However, there are a few factors that can affect the weldability of aluminum sheets. First, it is necessary to ensure that the surface of the aluminum sheet is clean and free from contaminants like oil, grease, or oxide layers. These contaminants can have a negative impact on the weld quality. Therefore, it is crucial to clean and prepare the surfaces to be welded properly. Second, aluminum sheets have a high thermal conductivity, which means that heat dissipates quickly. This can make it difficult to control the temperature during the welding process. To ensure a successful weld, it is important to have a skilled and experienced welder who can adjust the welding parameters accordingly. Lastly, aluminum sheets have a high coefficient of thermal expansion, which can result in distortion or warping during welding. To minimize these issues, techniques such as tack welding or clamping may be used to hold the sheets in position. In conclusion, aluminum sheets generally have good weldability due to their low melting point and excellent thermal conductivity. However, achieving high-quality welds and avoiding potential issues like contamination, distortion, or warping requires proper surface preparation, skilled welding techniques, and careful temperature control.

- Q: This question asks about the various grades of aluminum sheets and the impact of these grades on their pricing.

- <p>Aluminum sheets are categorized into different grades based on their composition and properties. The most common grades include 1000 series (99% pure aluminum), 3000 series (aluminum-manganese alloys), 5000 series (aluminum-magnesium alloys), and 6000 series (aluminum-magnesium-silicate alloys). Each grade has unique characteristics affecting their applications, such as corrosion resistance, strength, and formability. The price of aluminum sheets varies with the grade due to differences in purity, alloying elements, production complexity, and market demand. Purity and the addition of alloying elements can increase the cost, while the availability and demand in the market also influence pricing. For instance, 1000 series sheets are generally cheaper due to their high purity and lack of alloying, while 6000 series sheets, known for their strength and durability, command a higher price.</p>

- Q: What will reflect light more- aluminum foil or white paper?

- Indestructible okorder /

- Q: Are aluminum sheets suitable for heat sinks?

- Yes, aluminum sheets are suitable for heat sinks. Aluminum has excellent thermal conductivity, which allows it to efficiently transfer heat away from the source. It is also lightweight, cost-effective, and easily manufacturable, making it a popular choice for heat sink applications.

- Q: Are aluminum sheets suitable for medical applications?

- Yes, aluminum sheets are suitable for medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for medical equipment and devices. It is commonly used in the production of medical instruments, diagnostic imaging systems, and surgical trays. Additionally, aluminum sheets can be sterilized easily, further enhancing their suitability for medical applications.

- Q: Is it possible to install aluminum sheets on an existing roof structure?

- <p>Yes, aluminum sheets can be installed on existing roofs. This process typically involves removing the old roofing material and ensuring the roof structure is sound. Aluminum sheets are lightweight, durable, and resistant to corrosion, making them a popular choice for roof installations. They can be installed over a solid substrate, such as plywood or metal decking, and often require a proper underlayment to ensure watertightness. It's important to follow manufacturer guidelines and local building codes when installing aluminum sheets on an existing roof. Professional installation is recommended to ensure the roof's integrity and longevity.</p>

- Q: A 0.2412 gram sample of aluminum ore was dissolved in a dilute mineral acid. The solution was treated with an excess of sodium oxalate. The resultant aluminum oxalate precipitate was filtered, washed and redissolved in mineral acid, then titrated with 42.12 mL of 0.1098 N KMnO4. Calculate the percent of aluminum in the sample.

- errgwet

- Q: How do aluminum sheets compare to copper sheets in terms of conductivity?

- When it comes to conductivity, aluminum sheets and copper sheets have their differences. Copper is known for its exceptional ability to conduct electricity and is considered one of the most conductive metals available. Its high electrical conductivity allows electricity to flow through it with minimal resistance. On the other hand, aluminum, while still a good conductor of electricity, is not as conductive as copper. In fact, aluminum has about 61% of the conductivity that copper possesses. As a result, if high conductivity is a top priority, copper sheets would be the preferred option. However, if cost-effectiveness and lightweight properties are more important, aluminum sheets can still offer adequate conductivity for many applications. Ultimately, the decision between aluminum and copper sheets relies on the specific project requirements and the balance between conductivity, cost, and other factors.

Send your message to us

Thin Aluminum Sheets - 10 mm Aluminium Sheet for Industrial/Construction/Decorative

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords