Painted Aluminum Sheets 5x10 - Aluminium Alloy and Sheet for Building Industrial

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Alloy and Aluminium Sheet for Building Industrial Description:

Aluminium Alloy and Aluminium Sheet for Building Industrial is mainly used in billboards, building exterior decoration, bus body, high rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves and so on.

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc

2.Main Features of Aluminium Alloy and Aluminium Sheet for Building Industrial :

PVC or paper inter to protect the surface

Totally free from defects like white rust, oil patches

High Quality

Competitive Price

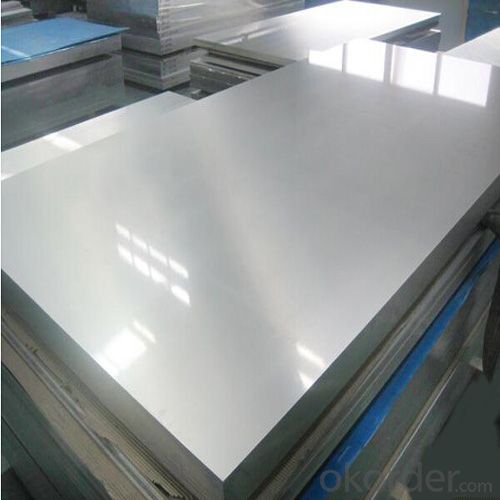

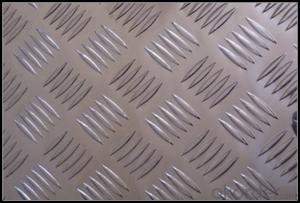

3.Aluminium Alloy and Aluminium Sheet for Building Industrial Images:

4. Aluminium Alloy and Aluminium Sheet for Building Industrial Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: i went on the apple education site cuz i was gonna order an aluminum today, and it isnt there anymore!!!! i was on it like 2 hours ago and it was...wtf!!! anyone know whuts up?

- Yes...All Aluminium Macbooks are now turned to Macbook Pros. So might want to try the Mid 2009 white macbook or you have to go with 13 Macbook Pro... vist www.parithi for details..

- Q: Can aluminum sheets be polished?

- Yes, aluminum sheets can be polished. Aluminum is a relatively soft metal, which makes it easier to polish compared to harder metals like stainless steel. Polishing aluminum sheets involves using abrasive materials such as sandpaper or polishing compounds to remove any imperfections, scratches, or oxidation on the surface. The process typically involves several stages of polishing with different grits of sandpaper or polishing compounds, gradually achieving a smoother and more reflective surface. Polished aluminum sheets are commonly used in various applications, including automotive parts, architectural elements, and decorative items, as the polishing process enhances the metal's appearance and provides a lustrous and reflective finish.

- Q: aluminum is 2.82x10^-8 ohm-m

- Aluminum with the same resistance as 50 meters of copper. (Resistance) = (Resistivity)(Length/Area) So if the resistivity changes by (2.82/1.72), then the length changes by (1.72/2.82). So the length of aluminum would be 50m(1.72/2.82) Length of aluminum would be 30.5 meters

- Q: Can aluminum sheets be anodized in different finishes?

- Different finishes can be achieved when anodizing aluminum sheets. Anodizing, an electrochemical process, enhances the natural oxide layer on aluminum, increasing its thickness and durability. It is possible to customize this process to achieve clear, colored, or textured surfaces. The finish type relies on factors such as alloy composition, anodizing technique, and desired appearance. Due to their corrosion resistance, aesthetic appeal, and ability to maintain color over time, anodized aluminum sheets find extensive use in architecture, automotive, and electronics industries.

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum sheets as a roofing material.

- <p>Aluminum sheets for roofing offer several advantages, including durability, resistance to rust and corrosion, lightweight nature, and energy efficiency due to reflective properties. They are also easy to install and maintain, and can be recycled, making them environmentally friendly. However, there are some disadvantages such as being more expensive than some other roofing materials, potential for denting if not properly installed, and noise issues during heavy rain or hail due to their lightweight nature. Additionally, they may require more frequent replacement compared to some other materials.</p>

- Q: Does anyone know why Mercury -(Thimerosal) is used in Flu Vaccinations and where Mercuryisnot used Aluminium in other vaccines ? While these are known to be toxic metals, can these cause headaches, severe hot burning heads and or Sinusitus ?

- It costs several cents more to manufacture 10 single dose vials that do not require mercury, than one multi-dose vial that does require mercury. Your health is worth just a few cents to these people. Aluminum is used in non-live virus vaccines in order to cause inflammation in the body, which produces a stronger immune response to the vaccine.

- Q: What specific requirements or considerations are necessary when using aluminum sheets in marine environments?

- <p>In marine environments, aluminum sheets must meet specific requirements to ensure durability and resistance to corrosion. These include using high-grade aluminum alloys, such as 5083 or 5086, known for their excellent resistance to saltwater corrosion. Protective coatings like anodizing or applying marine-grade paints can further enhance corrosion resistance. Additionally, the aluminum sheets should be designed to withstand the harsh conditions of marine environments, including high humidity, UV radiation, and mechanical stress. Regular maintenance and inspection are also crucial to prevent corrosion and ensure the longevity of aluminum structures in marine settings.</p>

- Q: Are the aluminum sheets suitable for manufacturing aircraft interiors?

- Yes, aluminum sheets are highly suitable for manufacturing aircraft interiors. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, making it ideal for aviation applications. It is resistant to corrosion, easy to fabricate, and can be easily formed into various shapes and sizes required for aircraft interiors. Additionally, aluminum sheets can be treated with coatings or finishes to meet specific design and functional requirements.

- Q: Can aluminum sheet be used for electrical conductivity applications?

- Yes, aluminum sheet can be used for electrical conductivity applications. Aluminum has good electrical conductivity properties, making it suitable for various electrical applications such as wiring, connectors, and conductive components.

- Q: I bought a house with aluminum wiring. Its about 1600 square feet. I have not had any problems with the electric but I read all these story's about how terrible aluminum wiring is.. is it worth the cost to replace? Most houses on my street have it also.. they have had no problems.. house was built in 79.How much would it cost to replace? would walls have to come down to do it?

- Aluminum wiring has caused many house fires and deaths. It is dangerous to keep using this type of wiring as it gets loose in the connections and loose electrical connections causes heat. Enough heat to melt the insulation within your walls. I have seen it. All it takes is heat and one smoldering board and your house is gone. Replace it for the safety of your family and your investment.

Send your message to us

Painted Aluminum Sheets 5x10 - Aluminium Alloy and Sheet for Building Industrial

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords