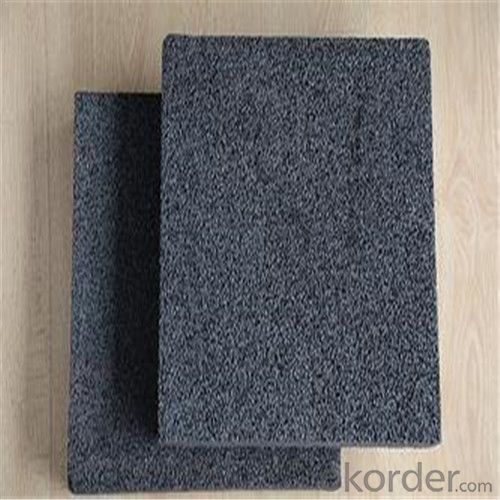

Ceramic Filter Plate - Thermal Silicon Carbide Ceramic Foam Filter 2024

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 g/m²

- Supply Capability:

- 1000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Silicon Carbide Ceramic Foam Filter for Foundry Industry

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | ||

| Material: | PU foam (polyurethane foam) | Size: | Customized | Mesh: | 10 ppi to 60 ppi |

| Property 1: | Mend structure of crystalloid | Property 2: | Reduce foreign matter | Property 3: | Stable chemical property |

| Property 4: | Stable purifying efficiency | polyurethane foam filter: | polyurethane foam |

Packaging & Delivery

| Packaging Details: | standard seaworthy/airworthy export packing |

| Delivery Detail: | 3 weeks |

Specifications

Silicon Carbide Ceramic Foam Filter work at more than 1500 Degree Celsius, filter moten iron and copper in related casting.

Silicon Carbide Ceramic Foam Filter

Ceramic Foam Filter is the third generation filter, compared with traditional filtering materials(ceramic honeycomb filter, extruded filter), our Ceramic Foam Filter have the advantages as below:

Silicon Carbide Ceramic Foam Filter Technical specification

Type Items | KFF-1 | |

Material | SiC | |

Working Temperature | 1500°C | |

Physical Properties | Porosity% | 80~90 |

Compression | ≥0.9Mpa | |

Volume Density | ≤0.6g/cm3 | |

Thermal Shock Resistance | 1100°C--Room Temperature ≥6 times | |

Main Chemical Content | Al2O3 | ≤30% |

SiC | ≥60% | |

SiO2 | ≤10% | |

ZrO2 | - | |

Others | 0~1% | |

Dimension | Round Shape | Φ30~Φ300mm |

Square Shape | 30~320mm | |

Thickness | 11~50mm | |

Pore Size | ppi | 8~40ppi |

mm | 0.1~15mm | |

Others about US:

- Q: The ceramic filter suddenly did not smoke, and later he was all right. What's the reason?

- The size of ceramic filter is generally on both sides of the vacuum tank, such as 50 square meters with 5 square meters of ceramic filter / ring ceramic filter plate combination (possible), there are 10 discs, the ceramic plate left a vacuum tank on the left of the 5 disc for filtration, vacuum filtration tank for the ceramic plate on the right right of the 5 disc. If a vacuum system temporarily fails, it may cause poor suction, no suction, and a normal operation at the other end.

- Q: Is the filter plate of the ceramic filter afraid of freezing?

- The ceramic filter plate by table and the distribution of a large number of porous capillary ceramic filter, when working in the water slurry channel is used so the microporous ceramic filter plate internal residual has a lot of water, such as low temperature, the inside of the frozen water volume will swell, causing damage to the ceramic the inside of the microporous filter plate structure.

- Q: What are the poor filtration effects of vacuum disc filters?

- The concentration can change the properties of the suspension, because the viscosity is no longer constant when the concentration of the suspension reaches a certain value, and belongs to the properties of non Newtonian fluid. For the suspension of fine particles, the filter cake resistance of low concentration slurry is higher than that of high concentration slurry, so the filter performance can be improved by increasing concentration. If the concentrate concentration is high and the general treatment capacity is high, the running overflow can be used to increase the concentrate content. The concentrate concentration is too high to influence the agitation, and the high productivity can be achieved by adjusting the overflow position.

- Q: What are the materials that make up the ceramic mold?

- From the development trend of rice, the development of ceramic membrane preparation technology mainly in the following 2 aspects: one is the porous membrane research, to further improve the already commercialized inorganic ultrafiltration and microfiltration membrane, nanofiltration membrane with molecular sieve, the development function of gas separation membrane and pervaporation membrane: two in dense membrane research solid electrolyte membrane, ultra-thin metal and its alloy film and ion conduction ability is research hotspot. The commercial porous membranes are mainly ultrafiltration and microfiltration membranes, and their preparation methods are mainly particle sintering and sol-gel. The former is mainly used for making microporous filter membranes, and commercial A1203 films are prepared by particle sintering method.

- Q: The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- As everyone knows, ceramic filter medium is a ceramic filter plate, microporous ceramic filter plate with a lot of distribution from the outside to the inside capillary effect, its mechanism is based on the capillary effect of microporous ceramic filter, filtration, the filtrate (generally refers to water) through these pores under the action of the vacuum suction pump, filter cake is trapped on the surface of the ceramic filter plate.

- Q: What is the working pressure of the ceramic filter?

- Generally speaking, there are two kinds of working pressure of ceramic filter: vacuum pressure and reverse flushing pressure.

- Q: Microporous ceramic filter plate cleaning

- In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- The filtration accuracy is the maximum particle size that the membrane can pass through.

- Q: Does the ceramic factory use hydrochloric acid?

- In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect

Send your message to us

Ceramic Filter Plate - Thermal Silicon Carbide Ceramic Foam Filter 2024

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 g/m²

- Supply Capability:

- 1000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches