Terra Bronze Aluminum Coil Embossed Treading Plates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of Embossed Aluminium Sheets Treading Plates

Alloy: 1050, 1060, 1100, 3003, 3005, 3105, 5052, etc

Thickness: 0.2mm~20mm

Temper: H14, 18, 24, 26, 32

Width: 10mm- 1500mm

2. Application of Embossed Aluminium Sheets Treading Plates

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Embossed Aluminium Sheets Treading Plates

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

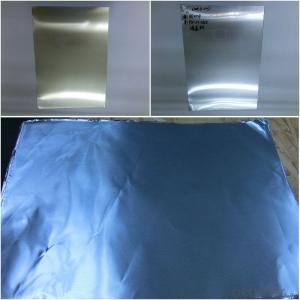

5. Image of Embossed Aluminium Sheets Treading Plates

6. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q: Are there any specific guidelines for handling and storing aluminum coils in warehouses?

- Yes, there are specific guidelines for handling and storing aluminum coils in warehouses. These guidelines aim to ensure the safety of workers and the integrity of the coils. Here are some key points to consider: 1. Handling: When moving aluminum coils, it is important to use appropriate lifting equipment such as cranes or forklifts with proper attachments to prevent damage. Avoid dragging or dropping the coils, as this can cause deformation or scratching. 2. Storage location: Choose a well-ventilated, dry, and clean area for storing aluminum coils. The storage area should be away from direct sunlight, heat sources, and any chemicals that could react with aluminum. Maintaining a consistent temperature and humidity level is crucial to prevent corrosion or other damage. 3. Stacking: When stacking aluminum coils, use suitable dunnage material such as wooden blocks or rubber mats between each coil to prevent direct contact. This helps to avoid scratches, dents, or other physical damage. Additionally, avoid excessive stacking height to prevent coil deformation or collapse. 4. Handling precautions: Always wear appropriate personal protective equipment (PPE) such as gloves and safety shoes when handling aluminum coils. This protects against potential injuries from sharp edges or falling objects. 5. Labeling: Clearly label each coil with important information such as weight, dimensions, alloy type, and any special handling instructions. This ensures proper identification and helps prevent mishandling or confusion. 6. Regular inspections: Conduct regular inspections of stored aluminum coils to check for any signs of damage or corrosion. If any issues are identified, take appropriate action promptly to prevent further damage. 7. Security measures: Implement security measures to prevent unauthorized access to the storage area. This helps protect the coils from theft or vandalism. It is important to note that specific guidelines may vary depending on the type and size of the aluminum coils, as well as local regulations and industry standards. It is recommended to consult the manufacturer's instructions or seek professional advice to ensure compliance with the appropriate handling and storage guidelines.

- Q: How do aluminum coils contribute to indoor air quality?

- Aluminum coils play a crucial role in maintaining and improving indoor air quality in various ways. Firstly, aluminum coils are commonly used in HVAC systems, which are responsible for heating, ventilation, and air conditioning in buildings. These coils help in the efficient transfer of heat and cooling, ensuring a comfortable indoor environment. By effectively regulating the temperature and humidity, aluminum coils help prevent the growth of mold, mildew, and other harmful microorganisms that thrive in damp and warm conditions. This, in turn, prevents the release of airborne spores and allergens that can negatively impact indoor air quality. Moreover, aluminum coils are highly resistant to corrosion and do not easily accumulate dirt, dust, or debris. This feature is crucial as dirty coils can lead to reduced airflow and inefficient cooling or heating, resulting in poor air quality. By utilizing aluminum coils, HVAC systems can maintain optimal performance, ensuring proper air circulation and filtration. This helps in removing pollutants, such as dust, pollen, pet dander, and volatile organic compounds (VOCs) from the indoor air, thus contributing to a healthier and cleaner environment. Another important aspect is that aluminum is a recyclable material, making it an environmentally friendly choice. By opting for aluminum coils in HVAC systems, we contribute to the reduction of waste and the conservation of natural resources. This aligns with sustainable practices and supports efforts to minimize the environmental impact of our indoor air conditioning systems. In summary, aluminum coils significantly contribute to indoor air quality by promoting efficient temperature and humidity control, preventing the growth of harmful microorganisms, facilitating proper air circulation, and enabling effective filtration. Additionally, their durability and recyclability make them an excellent choice for maintaining a healthy and sustainable indoor environment.

- Q: Can aluminum coils be painted or printed on?

- Indeed, aluminum coils possess the capability to undergo painting or printing processes. Aluminum, being a versatile material, can be coated or painted to achieve a wide range of finishes and colors. Prior to painting or printing, the surface of aluminum coils can be readied through a pre-treatment process involving cleaning, etching, and the application of a primer. This pre-treatment ensures that the surface is prepared adequately. The painting of aluminum coils involves the application of a coating system that typically comprises a primer, a color coat, and a protective topcoat. Various methods, such as spraying, roll coating, or coil coating, can be employed to apply the paint. Coil coating, specifically, is a commonly utilized method wherein the paint is applied to the coil prior to shaping it into the desired form. This method guarantees a uniform and consistent finish. On the other hand, printing on aluminum coils is also feasible using techniques like screen printing, digital printing, or lithography. These techniques enable the printing of intricate designs, patterns, or even photographs onto the surface of the aluminum coil. One must consider that the selection of the paint or printing method may depend on specific requirements such as durability, weather resistance, or aesthetic preferences. Additionally, ensuring a successful and long-lasting paint or print finish on aluminum coils necessitates proper surface preparation, appropriate coating selection, and adherence to recommended application guidelines.

- Q: Just wondering if an aluminum and Fluoride bond can be created by boiling fluoridated water in aluminum cookware?

- i would say yes because ions are released from most things when heated

- Q: What is the maximum temperature aluminum coils can withstand?

- The maximum temperature that aluminum coils can withstand typically ranges from 300 to 500 degrees Fahrenheit, depending on the specific alloy and application.

- Q: How do aluminum coils contribute to sustainable manufacturing practices?

- The numerous environmental and economic benefits of aluminum coils make them crucial for promoting sustainable manufacturing practices. To start, aluminum is an incredibly recyclable material, with almost 75% of all aluminum ever produced still in use today. This means that aluminum coils can be recycled and reused multiple times without losing their quality or performance. Unlike producing new aluminum, recycling aluminum requires only a fraction of the energy, resulting in significant energy savings and reduced greenhouse gas emissions. Furthermore, the lightweight nature of aluminum coils contributes to energy efficiency in transportation and reduces fuel consumption during shipping. This characteristic allows for more efficient use of resources, as less material is needed to achieve the same strength and durability compared to other metals. Consequently, this not only reduces the overall weight of products but also lowers the energy required for their fabrication and transportation. Moreover, the excellent corrosion resistance of aluminum coils extends their lifespan and reduces the need for frequent replacement. This factor not only saves resources but also reduces waste generation and associated environmental impacts. Additionally, aluminum coils are non-toxic and do not release harmful substances into the environment, making them a safe and sustainable choice for various manufacturing applications. In terms of economic benefits, aluminum coils contribute to sustainable manufacturing practices by offering cost savings throughout their lifecycle. The recyclability of aluminum reduces the need for raw material extraction, thereby lowering operational costs and dependence on virgin resources. Additionally, the lightweight nature of aluminum coils allows for more efficient use of energy and resources, resulting in reduced manufacturing and transportation costs. In conclusion, aluminum coils are essential for promoting sustainable manufacturing practices due to their recyclability, lightweight nature, corrosion resistance, non-toxicity, and cost-saving benefits. By integrating aluminum coils into manufacturing processes, companies can reduce their environmental footprint, conserve resources, promote energy efficiency, and contribute to a more sustainable and greener future.

- Q: Is it possible to utilize aluminum coils in the manufacturing process of solar panels?

- <p>Yes, aluminum coils can be used in the production of solar panels. Aluminum is a common material used in solar panel frames due to its lightweight, high strength, and excellent heat dissipation properties. It also offers good resistance to corrosion, which is crucial for outdoor applications. Aluminum coils are often chosen for their ease of manufacturing and cost-effectiveness, making them a suitable choice for constructing the frame or support structure of solar panels.</p>

- Q: Are aluminum coils resistant to oil and grease?

- Yes, aluminum coils are generally resistant to oil and grease.

- Q: I'm asking about the aluminum tabs on soda cans. I've heard mixed things.

- Yes, if you are willing to drive and deliver the aluminum tabs to a recycling site, you can probably be reimbursed for the tabs. However, if you'd rather just donate them to a great cause, you can send them to Shriner's Hospitals, or someone you know locally who is involved with Shriner's. I'm sure they would gladly deliver them when they visit with thier sick child for treatment at these free hosiptals! If you don't know of anyone who uses the Shriner's Hospital services, please email me back and I'll make arrangements for your pop-tabs to get to the Shriner's Hospital in Philadelphia, PA every 3 months or so. My child visits them every 3 months!!!!

- Q: Are aluminum coils suitable for outdoor applications?

- Yes, aluminum coils are suitable for outdoor applications. Aluminum is known for its excellent corrosion resistance, making it a popular choice for outdoor use. It is not prone to rust or deterioration when exposed to moisture, sunlight, or harsh weather conditions. Additionally, aluminum coils are lightweight, durable, and have a high strength-to-weight ratio, making them ideal for various outdoor applications such as roofing, gutters, air conditioning systems, and outdoor furniture. Moreover, aluminum is a highly recyclable material, making it an environmentally-friendly choice for outdoor projects. Overall, aluminum coils are a reliable and practical option for outdoor applications.

Send your message to us

Terra Bronze Aluminum Coil Embossed Treading Plates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords