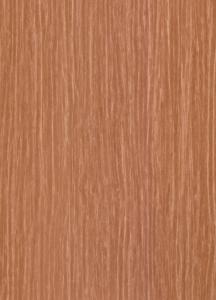

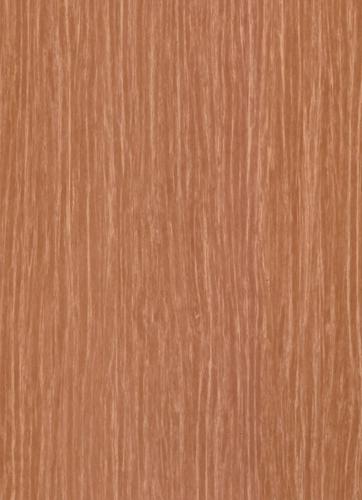

Customized Embossed Aluminum Coil with Wood Grain

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: Can aluminum coils be used in the production of electronic devices?

- Yes, aluminum coils can be used in the production of electronic devices. Aluminum is a commonly used material in the electronics industry due to its excellent conductivity, lightweight nature, and resistance to corrosion. Aluminum coils are often utilized in various electronic components like transformers, inductors, and coils for power supply applications.

- Q: Explain the key differences between aluminum coil welding and soldering processes.

- <p>Aluminum coil welding and soldering are two distinct methods used in metal joining. Welding involves the fusion of aluminum coils using heat to create a strong bond between the metals. This process can be done with various techniques such as MIG, TIG, or laser welding, and it results in a permanent joint. Soldering, on the other hand, is a process that uses a filler metal with a lower melting point than the base metal (aluminum in this case) to join the materials. The joint is not as strong as a welded joint, and the process does not involve melting the base metal. Soldering is often used for electrical connections or when a less permanent bond is required. In summary, welding creates a stronger, more permanent bond by melting the base metal, while soldering uses a filler metal to create a less permanent bond.</p>

- Q: I am looking to bake some Buffalo wings and am wondering if it's alright to bake them in an aluminum pan (disposable or otherwise). I will be brushing/basting the chicken in the sauce not 'drowning' the chicken in it. I have heard that acidic sauces like Tomato sauce (less acidic than wing sauce) should not be cooked in aluminum (stovetop pans bakeware) because of some chemical interaction, but I've seen those big foil pans full of pasta spaghetti sauce at wedding, etc. Is the whole acid/aluminum thing true or an old cooking myth?

- I dont know about the myth, but I can tell you that when we were tailgating we baked them in aluminum pans and they turned out fine.....good luck.

- Q: And what are the advantages/disadvantages of steel aluminum in building cars?Which would be better for building cars?

- Similarities - They are both metals, conduct electricity and heat and deform elastically then plastically. Difference - every mechanical property there is! Density, elastic modulus (stiffness), strength and hardness are all higher for steel. But, for building cars it is about design, weight, forming, manufacturing, joining and cost. Better depends on what you are trying to acheive - cost or weight saving - and there is not a hard and fast rule as to which metal helps which. Have a look at either the Jaguar S type which is aluminium (as is the Audi A6). Most Ford cars are still steel (as are Renault). Check out the crash test results.

- Q: What are the rules and regulations concerning the disposal of old aluminum coils?

- <p>Yes, there are regulations on the disposal of old aluminum coils. These regulations vary by country and region, but generally, they aim to prevent environmental pollution and promote recycling. In the United States, for example, the Environmental Protection Agency (EPA) sets guidelines for recycling and disposing of scrap metal, including aluminum. Businesses and individuals are often required to recycle aluminum coils rather than sending them to landfills. Proper disposal may involve sorting, cleaning, and sending the coils to recycling facilities that can process and reuse the material. Violations of these regulations can result in fines and penalties. It's important to check local and national regulations for specific requirements.</p>

- Q: How does the alloy composition affect the properties of aluminum coils?

- The properties of aluminum coils are significantly influenced by their alloy composition. To enhance specific characteristics, aluminum is often combined with elements like copper, manganese, magnesium, and zinc. The strength of aluminum coils is a key property that is impacted by the alloy composition. Copper and zinc alloys, such as the popular 6061 or 7075 aluminum alloys, are renowned for their high strength, making them suitable for structural purposes. Conversely, manganese and magnesium alloys, like the 3003 or 5052 aluminum alloys, offer improved formability and are commonly used in the construction of automotive components or packaging materials. Corrosion resistance is also affected by the alloy composition of aluminum coils. For example, the addition of magnesium in alloys like 5052 or 5083 enhances their resistance to corrosion in marine environments, making them ideal for boat building or other marine applications. On the other hand, copper alloys possess excellent resistance to atmospheric corrosion and are frequently utilized in outdoor structures or architectural applications. The thermal conductivity of aluminum coils is another crucial property impacted by the alloy composition. Copper alloys exhibit high thermal conductivity, making them efficient for heat transfer applications such as heat exchangers or radiators. Aluminum-magnesium alloys, like 3003 or 3004, have lower thermal conductivity, making them suitable for applications where heat dissipation is desired, such as heat sinks in electronic devices. Additionally, the alloy composition can influence the electrical conductivity of aluminum coils. Copper alloys, with their high electrical conductivity, are commonly used in electrical wiring and conductors. However, aluminum-magnesium alloys, despite having lower electrical conductivity than copper, are still widely employed in electrical transmission lines and overhead power cables due to their lightweight nature. In conclusion, the alloy composition of aluminum coils plays a crucial role in determining their properties. It affects their strength, corrosion resistance, thermal conductivity, and electrical conductivity, allowing them to be customized for specific applications.

- Q: Who knows about how much money can be sold in a three metre high similar aluminum door?

- How wide is it, mainly to see the door you have multiple components, scrap is generally about 10 yuan a kilogram!

- Q: Can aluminum coils be used for insulation purposes?

- No, aluminum coils cannot be used for insulation purposes as aluminum is a conductor of heat and does not possess insulating properties.

- Q: Can aluminum coils be used in signage applications?

- Yes, aluminum coils can be used in signage applications. Aluminum is a popular material for signage due to its durability, corrosion resistance, and lightweight nature. It can be easily formed into various shapes and sizes, making it suitable for different types of signage such as outdoor signs, billboards, trade show displays, and more. Additionally, aluminum coils offer excellent weather resistance, ensuring that the signage remains intact and vibrant even in harsh environmental conditions. The versatility and longevity of aluminum make it a preferred choice for signage applications in various industries.

- Q: Can aluminum coils be used for electronic enclosures?

- Indeed, electronic enclosures can utilize aluminum coils. The lightweight characteristic, remarkable thermal conductivity, and corrosion resistance render aluminum a favored option. These coils can be effortlessly molded into diverse dimensions and configurations, making them exceptionally suitable for personalized enclosure designs. Moreover, aluminum exhibits electromagnetic shielding qualities, effectively safeguarding delicate electronic components against external disturbances. All in all, aluminum coils prove to be a fitting alternative for electronic enclosures, offering durability, functionality, and aesthetic allure.

Send your message to us

Customized Embossed Aluminum Coil with Wood Grain

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords