Tencate Miragrid Geogrids with Low Elongation for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

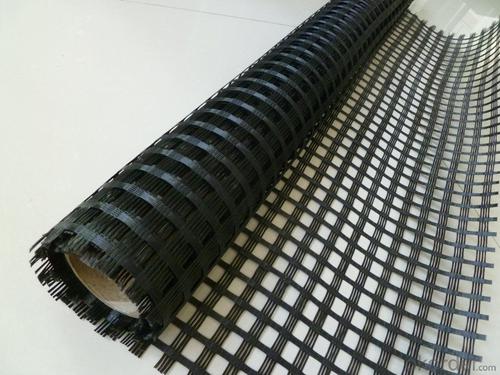

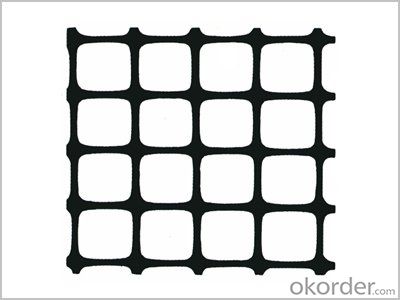

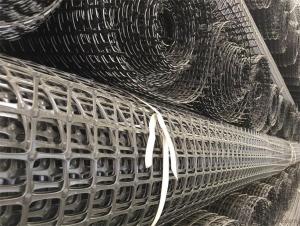

Our niaxial geogrids are made from polyester yarn, knitted or woven into a stable structure and have a PVC or polymeric coating. These flexible, user-friendly geogrids are inert to biological degradation and resistant to creep, strain and naturally found chemicals.

Bonded Geogrids are flat structures, where two or more series of strip elements made of polyester coated with polyethylene, are linked at regular intervals by means of bonding.

Woven Geogrids are flat structures in the shape of a net made of high module synthetic fibres, that may also be coated with a further protection layer, using synthetic material (usually PVC or other polymer).

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geogrids resistant to seismic forces?

- Yes, geogrids are designed to be resistant to seismic forces. They are made from durable materials that can withstand the dynamic forces generated during an earthquake, providing stability and reinforcement to soil and structures. Geogrids help distribute seismic forces and prevent soil liquefaction, making them a reliable solution in areas prone to earthquakes.

- Q: Can geogrids be used in riverbank protection projects?

- Yes, geogrids can be used in riverbank protection projects. Geogrids are effective in stabilizing soil and preventing erosion, making them suitable for reinforcing riverbanks and providing structural support. They can help to mitigate the effects of water flow and protect the riverbank from further damage.

- Q: What are the physical properties of Geosynthetics

- 2, the quality of unit area: the quality of the unit area of the unit area of geosynthetics. It reflects the properties of materials in many aspects, such as tensile strength, bursting strength and mechanical properties such as porosity, permeability and hydraulic performance, usually expressed as g / m2, is one of the important physical properties of geosynthetics. The quality of geotextile and geomembrane per unit area is affected by the density of raw materials, and the influence of thickness, admixture and water content. The commonly used geotextile fabric area quality is generally in the range of 50 ~ 1200g / m2

- Q: How to connect the geogrid with the panel in the reinforced earth retaining wall?

- When the geogrid is laid in the curve and the corner, the adjacent earthwork grid is currently used in the reinforced earth retaining wall of the assembled panel, and the common wall of the assembled panel module will have gaps or overlaps (see Figure 1). For the outward bending of the geogrid, there are different forms such as rectangle, hexagon, shape, L shape and groove shape. Panel module will appear at the corner of the gap,In order to ensure the continuity of the reinforced soil, laying in the void design based on the engineering environment need to be flexible, prefabricated into various shapes, can provide the same type of geogrid small pieces of good, and cover all the reinforced area; for bend shop visual effect; can also use color cement, add art wall. No panel reinforcement design of geogrid, in the corner there will be some overlap in geogrid, geogrid reinforced earth retaining wall is also called anti package type or wrap-reinforcedearth retaining wall, the wall is made of mesh bags to fill the overlap coefficient of friction will be reduced, must be laying a layer of 10mm ~ 20mm thick the soil geogrid anti package into each layer of geogrid is a special connecting rod is connected with the shape of the coarse sand layer, separate the two layer of Geogrid to ensure friction resistance. As a whole, the mesh bag filling has been mixed for local growth of grass and shrub seeds, seeds, after months of growth after the formation of green ecological wall. The utility model not only protects the safety of the geogrid, but also beautifies the environment of the retaining wall project.

- Q: Can geogrids be used in reinforcement of soft ground?

- Yes, geogrids can be used in the reinforcement of soft ground. Geogrids are commonly used to improve the stability and load-bearing capacity of weak or soft soil by distributing the applied loads and reducing settlement. They are effective in reinforcing soft ground and can provide increased strength and stability to the soil, making them a suitable solution for various civil engineering and construction projects.

- Q: What is the GDL geogrid

- First, the characteristics of uniaxial tensile plastic geogrid:1, the polymer into a linear state and the formation of a uniform distribution, high strength of the node of the long elliptical mesh integral structure. This kind of structure has high tensile strength and rigidity, and it provides the ideal chain system of bearing and diffusion of soil;

- Q: Who can say the geogrid, fiberglass mesh and geotextile what is the difference, from the material function, the use of all aspects of speaking, if the answer is good, I add the score

- A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid. Engineering applications: highway, railway, bridge, road, pier, dam, slag field, such as soft soil foundation reinforcement, retaining wall and pavement crack resistance engineering and other fields.

- Q: How do geogrids reinforce slopes?

- Geogrids reinforce slopes by providing additional support and stability to the soil. They are typically made of high-strength materials, such as polyester or polypropylene, and are installed within the soil layers to enhance their strength. The geogrids act as a barrier, preventing soil movement and erosion, while distributing the forces exerted on the slope more evenly. This reinforcement technique helps to prevent slope failures and increases the overall stability of the slope.

- Q: How do geogrids improve the performance of geosynthetic-reinforced retaining walls?

- Geogrids improve the performance of geosynthetic-reinforced retaining walls by providing additional stability and strength. They work by distributing the lateral forces exerted on the wall more evenly, reducing the chances of wall failure or deformation. Geogrids also enhance the overall load-bearing capacity of the wall, allowing for the construction of taller and more efficient retaining structures.

- Q: How do geogrids improve the stability of earth retaining structures?

- Geogrids improve the stability of earth retaining structures by providing reinforcement and increasing the tensile strength of the soil. They act as a stabilizing element by effectively distributing the loads and reducing the potential for soil movement. Additionally, geogrids enhance the overall performance of these structures by preventing differential settlement and minimizing the risk of wall failure and deformation.

Send your message to us

Tencate Miragrid Geogrids with Low Elongation for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords