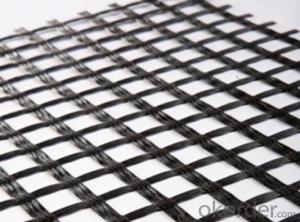

Tencate Miragrid Biaxial Geogrids for Highway Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

1)fiberglass geogrid with CE certificate

2)Materials:fiberglass

3) Tensile strength:MD/CD:30 ~ 200kn/m

4)WIdth:1 ~ 6m

Temperature Resistance (Centigrade): -100~290

Surface Processing: Modified asphalt or Polymer and self adhesive

Packing: With PE bags

Material Major Advantages

Geogrid application is a way of soil reinforcement, On soil surface a plate is created according to the thickness of a corresponding geogrid: 50 mm, 100 mm, 150 mm, 200 mm (this standard range of products is manufactured by “Technostroytex” LLC).

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the differences between geogrids and geocomposites?

- Geogrids and geocomposites are both used in soil stabilization and reinforcement applications, but they have some key differences. Geogrids are typically made from high-strength polymers or fiberglass, and they have a grid-like structure with open spaces. They are designed to provide tensile strength and distribute loads across a wider area. Geogrids are mainly used for reinforcing soils, retaining walls, and roadways. On the other hand, geocomposites are multi-layered materials that combine different geosynthetic components. They usually consist of a geotextile fabric or membrane bonded to a geogrid or geonet layer. Geocomposites offer a combination of functions such as filtration, drainage, separation, and reinforcement. They are commonly used in applications like erosion control, landfill engineering, and drainage systems. In summary, while geogrids focus on reinforcement and load distribution, geocomposites offer a more versatile solution by combining multiple functions in a single product.

- Q: What is the recommended geogrid aperture shape for specific applications?

- The recommended geogrid aperture shape for specific applications depends on various factors such as soil type, load requirements, and installation method. Generally, square or rectangular aperture shapes are preferred for applications involving stabilization and reinforcement of soils, while triangular or diamond-shaped apertures are more suitable for applications requiring high tensile strength and flexibility. It is crucial to consult geosynthetic experts or manufacturers to determine the most appropriate geogrid aperture shape for a specific project.

- Q: Are geogrids resistant to corrosion?

- Yes, geogrids are generally resistant to corrosion due to their material composition, which is typically made of high-density polyethylene (HDPE) or polypropylene (PP). These materials are highly resistant to chemicals, moisture, and environmental factors, making geogrids suitable for long-term use in various applications without the risk of corrosion.

- Q: How do geogrids prevent lateral spreading of soil?

- Geogrids prevent lateral spreading of soil by providing tensile strength and reinforcement to the soil, effectively increasing its stability and preventing it from shifting or sliding laterally.

- Q: What are the differences between geogrids and geosynthetic clay liners?

- Geogrids and geosynthetic clay liners (GCLs) are two different types of geosynthetics used in various civil engineering and environmental applications. Geogrids are typically made of high-strength polymer materials, such as polypropylene or polyester, and are designed to provide reinforcement and stabilization to soil structures. They have a grid-like structure with open apertures, allowing soil particles to interlock within the grid, improving load distribution and preventing soil erosion. Geogrids are commonly used in slope stabilization, retaining walls, and road construction. On the other hand, geosynthetic clay liners (GCLs) are composite materials consisting of a layer of bentonite clay sandwiched between two geotextile layers. Bentonite clay is highly absorbent and expands upon contact with water, creating a low permeability barrier. GCLs are primarily used as hydraulic barriers for containment applications, such as landfill liners, pond liners, and wastewater treatment facilities. They provide excellent resistance to liquid flow and act as a barrier to prevent the migration of contaminants. In summary, the main differences between geogrids and geosynthetic clay liners lie in their composition, purpose, and applications. Geogrids focus on soil reinforcement and stabilization, while GCLs are primarily used as barriers to control liquid flow and prevent the migration of contaminants.

- Q: What is the lifespan of a geogrid?

- The lifespan of a geogrid can vary depending on several factors such as the type and quality of the material used, the environmental conditions it is exposed to, and the level of maintenance and care it receives. However, on average, a geogrid can have a lifespan ranging from 20 to 50 years.

- Q: Are geogrids effective in preventing soil erosion on hillsides?

- Yes, geogrids are effective in preventing soil erosion on hillsides. Geogrids are typically made from durable materials that reinforce the soil, providing stability and preventing it from being washed away by water or eroded by wind. By distributing the forces exerted on the soil, geogrids help to maintain its integrity and prevent erosion, making them a reliable solution for protecting hillsides against soil erosion.

- Q: What are the maintenance requirements for geogrid-reinforced structures?

- The maintenance requirements for geogrid-reinforced structures typically involve regular inspections to check for any signs of damage or degradation. This includes assessing the condition of the geogrid, ensuring proper connection between the geogrid and the surrounding materials, and monitoring any settlement or movement of the structure. Additionally, vegetation management is important to prevent root intrusion which can compromise the integrity of the geogrid. Regular cleaning and clearing of debris is also necessary to maintain the functionality and lifespan of geogrid-reinforced structures.

- Q: Is it the same thing as two way tgsg30-30 geogrid and two - way plastic geogrid

- Biaxial stretching plastic geogrid is a general term, it can also be called biaxial tensile polypropylene geogrid";

- Q: What are the design considerations for geogrids in mechanically stabilized earth walls?

- Some of the key design considerations for geogrids in mechanically stabilized earth (MSE) walls include selecting the appropriate geogrid material and strength, determining the required geogrid spacing and length, considering the connection and anchorage details, assessing the interface friction between the geogrid and the soil, and evaluating the long-term durability and performance of the geogrids in the specific environmental conditions. Additionally, proper installation practices and quality control measures should be implemented to ensure the geogrids are correctly positioned and tensioned within the MSE wall system.

Send your message to us

Tencate Miragrid Biaxial Geogrids for Highway Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords