SWRH42A 42B 57A Galvanized Steel Wire Rod

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

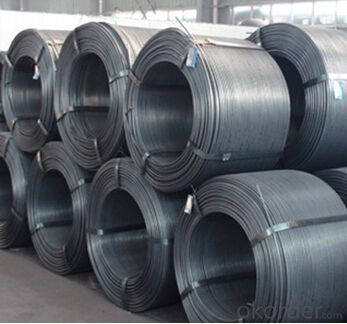

SWRH42A 42B 57A Galvanized Steel Wire Rod

Details of the SWRH42A 42B 57A Galvanized Steel Wire Rod

| Steel Grade | Q195-Q235,Q235,SAE 1008-1018 Hot Rolled Steel Wire Rod |

| Diameter | 5.5, 6.5, 7,8, 9,10, 12,14mm.etc. |

| Coil weight | 2m.t. |

| Application | drawing, construction materials, machinery parts,construction for Houses, Bridges, Roads,Packing |

| Deliver Time | 25-30 days after receipt of L/C or deposit by T/T |

| Packing | In coils, loading in container or by bulk vessel |

| Payment terms | 1).100% irrevocable L/C at sight. |

| 2).30% T/T prepaid and the balance against the copy of B/L. | |

| 3).30% T/T prepaid and the balance against L/C |

| Chemical Composition(%) | ||||||

| C | Mn | Si | S | P | Cr | |

| SAE1006B | 0.03~O.07 | ≤0.32 | ≤0.30 | ≤0.045 | ≤0.040 | 0.3-0.35 |

| Mechanical properties | ||||||

| Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

| 250-280 | 350-380 | ≥32 | ||||

| Grade | Chemical Composition(%) | |||||

| C | Mn | Si | S | P | Cr | |

| SAE1008B | 0.10max | 0.3~O.50 | 0.15max | 0.050max | 0.040 max | 0.3-0.35 |

| Mechanical properties | ||||||

| Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

| ≥195 | 315-430 | ≥30 | ||||

Supplier of the SWRH42A 42B 57A Galvanized Steel Wire

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Delivery of the SWRH42A 42B 57A Galvanized Steel Wire Rod

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the main applications of special steel in the pharmaceutical industry?

- Special steel is widely used in the pharmaceutical industry for various applications. One of the main applications is in the manufacturing of high-quality equipment such as tanks, vessels, and pipes that are required for the storage and transportation of pharmaceutical products. Special steel is preferred due to its corrosion resistance, durability, and ability to maintain product purity. Additionally, special steel is utilized in the production of precision tools and instruments used in pharmaceutical research, development, and quality control processes. Moreover, special steel is essential in the construction of cleanrooms and controlled environments, ensuring the hygienic and sterile conditions required in pharmaceutical manufacturing.

- Q: Can special steel be used in the manufacturing of household appliances?

- Yes, special steel can be used in the manufacturing of household appliances. Special steel, also known as alloy steel, offers a range of desirable properties such as high strength, durability, and resistance to corrosion and wear. These characteristics make it suitable for various applications, including the production of household appliances. Household appliances such as refrigerators, ovens, dishwashers, and washing machines require materials that can withstand constant use, high temperatures, and exposure to water and chemicals. Special steel fulfills these requirements and provides a reliable and long-lasting solution. For example, stainless steel is a type of special steel commonly used in household appliances due to its corrosion resistance and hygienic properties. It is used in appliance components such as refrigerator doors, oven interiors, and dishwasher interiors. Stainless steel is easy to clean, maintains its appearance over time, and does not react with food or other substances, making it an ideal choice for household appliances. Additionally, special steel alloys can be used to enhance specific properties needed in different appliances. For instance, heat-resistant alloys can be utilized in ovens or stovetops, while high-strength steel alloys can be employed in appliances that require structural integrity, like washing machines or dryers. In summary, special steel can definitely be used in the manufacturing of household appliances. Its various properties, including strength, durability, resistance to corrosion, and versatility, make it an excellent material choice for ensuring the performance, longevity, and safety of household appliances.

- Q: How is shock-resistant alloy steel used in the production of impact-resistant parts?

- Shock-resistant alloy steel is used in the production of impact-resistant parts due to its high strength and ability to withstand sudden impact forces without fracturing or deforming. This steel is specifically designed to absorb and disperse energy, making it ideal for applications where parts are exposed to repeated impacts or high-stress environments. By using shock-resistant alloy steel, manufacturers can create durable and reliable impact-resistant parts that can withstand heavy loads, reduce the risk of failure, and increase the overall safety and longevity of the component or equipment.

- Q: Can special steel be used in automotive engine components?

- Yes, special steel can be used in automotive engine components. Special steel, also known as alloy steel, is specifically designed to have enhanced properties such as increased strength, toughness, and heat resistance. These properties make it ideal for use in critical engine components that are subjected to high temperatures, stress, and wear. In automotive engines, special steel can be used in various components such as crankshafts, camshafts, connecting rods, valves, and piston rings. These components are subjected to extreme conditions, including high temperatures, pressure, and rotational forces. Special steel provides the required strength and durability to withstand these conditions, ensuring reliable engine performance and longevity. The use of special steel in automotive engine components offers several advantages. Firstly, it increases the strength and load-carrying capacity of the components, allowing them to handle higher power and torque outputs. Secondly, special steel improves the fatigue resistance and durability of the components, reducing the risk of failure and extending their service life. Lastly, special steel can withstand the high temperatures and thermal cycling experienced in the engine, preventing deformation and maintaining dimensional stability. Overall, the use of special steel in automotive engine components is crucial for achieving optimal performance, reliability, and longevity. It ensures that the engine can withstand the demanding conditions it operates under, providing a smoother and more efficient driving experience.

- Q: How does special steel contribute to the industrial equipment industry?

- The industrial equipment industry greatly relies on special steel for its superior strength, durability, and ability to withstand harsh conditions. Specially engineered steel alloys possess exceptional properties that suit a wide range of applications in industrial equipment. One of the main advantages of special steel is its ability to endure high temperatures and pressure, making it ideal for producing components like boilers, turbines, and heat exchangers. With its high heat resistance, special steel ensures efficient and reliable operation in demanding environments, enhancing performance and safety. Moreover, special steel is well-known for its excellent corrosion resistance, making it suitable for manufacturing equipment that encounters corrosive substances. This includes chemical processing equipment, oil and gas pipelines, and marine structures. By utilizing special steel in these applications, the industrial equipment industry can prolong operational lifetimes, reduce maintenance costs, and minimize the risk of catastrophic failures. Special steel also contributes to the industry by enabling the production of equipment with superior mechanical properties. Its unique composition and heat treatment processes increase strength, toughness, and wear resistance. Consequently, industrial equipment made from special steel can handle heavy loads, endure extreme conditions, and provide long-lasting performance. Furthermore, special steel alloys can be customized to meet specific requirements, allowing for the production of tailor-made components. This flexibility empowers the industrial equipment industry to design and manufacture equipment that precisely meets the diverse needs of sectors such as aerospace, automotive, energy, and construction. The versatility and adaptability of special steel play a crucial role in driving innovation and technological advancements within the industry. To summarize, special steel significantly contributes to the industrial equipment industry by providing exceptional strength, durability, resistance to harsh conditions, and customized solutions. Its unique properties make it an essential material for manufacturing a wide range of equipment, ultimately enhancing performance, reliability, and safety across various sectors.

- Q: What are the different welding techniques for special steel?

- There are several different welding techniques used for special steel, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and submerged arc welding (SAW). Each technique offers unique advantages and is chosen based on factors such as the type of special steel being welded, the desired weld quality, and the specific requirements of the project.

- Q: What are the different tempering techniques used for special steel?

- There are several tempering techniques used for special steel, including air tempering, oil tempering, water tempering, and salt bath tempering. Each technique involves heating the steel to a specific temperature and then cooling it at a controlled rate to achieve the desired level of hardness and toughness.

- Q: How is special steel used in toolmaking?

- Special steel is widely used in toolmaking due to its exceptional properties that make it highly suitable for creating durable and high-performance tools. Toolmaking involves the manufacturing of various tools such as drills, saws, cutting tools, dies, and molds, among others. Special steel is utilized in toolmaking to ensure that these tools possess the necessary strength, hardness, toughness, and wear resistance required for their intended applications. One of the primary advantages of special steel in toolmaking is its high strength. Special steel is alloyed with elements such as chromium, molybdenum, vanadium, and tungsten, which enhance its strength and hardness. This enables the tools to withstand heavy loads, resist deformation, and maintain their structural integrity even under extreme working conditions. In addition to strength, special steel also exhibits excellent hardness. Tools made from special steel undergo heat treatment processes such as quenching and tempering to achieve the desired hardness level. This hardness is crucial for toolmaking as it enables the tools to efficiently cut, drill, or shape various materials without getting damaged or worn out easily. Furthermore, special steel possesses exceptional toughness. Toughness refers to a material's ability to absorb energy and resist cracking or fracturing. Tools made from special steel can withstand impact and heavy loads, ensuring that they do not break or chip easily during use. This is particularly important in toolmaking as tools often encounter high-stress situations where toughness is vital to prevent premature failure. Another significant advantage of special steel in toolmaking is its excellent wear resistance. Tools are subjected to constant friction, abrasion, and contact with hard materials, leading to wear and tear. Special steel is specifically designed to resist wear, enabling the tools to maintain their cutting or shaping abilities over extended periods. This not only prolongs the tool's lifespan but also ensures consistent performance and high-quality output. Special steel is also known for its corrosion resistance, which is beneficial in toolmaking, especially when working with corrosive materials or in harsh environments. The inclusion of certain elements like chromium in special steel enhances its resistance to corrosion, preventing rust and deterioration of the tools. In conclusion, special steel plays a crucial role in toolmaking by providing the necessary strength, hardness, toughness, wear resistance, and corrosion resistance. These properties enable the tools to perform effectively and efficiently, ensuring durability and longevity. Whether it is for cutting, drilling, shaping, or molding, special steel is an essential material in the production of high-quality tools that meet the demands of various industries.

- Q: What are the different types of bearing steel?

- There are several different types of bearing steel, including high-carbon chromium steel, high-carbon chromium-molybdenum steel, and case-hardened steel.

- Q: What are the different corrosion-resistant special steel alloys?

- There are several corrosion-resistant special steel alloys that are commonly used in various industries. Some of the most popular ones include stainless steel, duplex stainless steel, super duplex stainless steel, and nickel-based alloys. Stainless steel is a widely used corrosion-resistant alloy that contains a minimum of 10.5% chromium. It forms a protective layer of chromium oxide on its surface, preventing further corrosion. Stainless steel is highly resistant to rust, staining, and pitting, making it suitable for applications in the food processing, chemical, and marine industries. Duplex stainless steel is a combination of both austenitic and ferritic stainless steels. It offers excellent resistance to corrosion, particularly in environments with high chloride ion concentrations. Duplex stainless steel is commonly used in the oil and gas, chemical, and desalination industries. Super duplex stainless steel is a higher strength version of duplex stainless steel. It offers enhanced corrosion resistance and mechanical properties, making it ideal for applications in harsh environments such as offshore oil and gas platforms, chemical processing plants, and seawater desalination systems. Nickel-based alloys, such as Inconel and Hastelloy, are known for their exceptional resistance to corrosion and high-temperature environments. These alloys are commonly used in industries such as aerospace, chemical processing, and power generation, where resistance to both corrosion and heat is critical. These corrosion-resistant special steel alloys provide various options for industries that require materials with excellent durability and resistance to corrosive environments. The choice of alloy depends on the specific application, operating conditions, and desired performance characteristics.

Send your message to us

SWRH42A 42B 57A Galvanized Steel Wire Rod

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords