Wall Angle Ceiling Grid System EGT Suspension Ceiling Grid System EGT

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

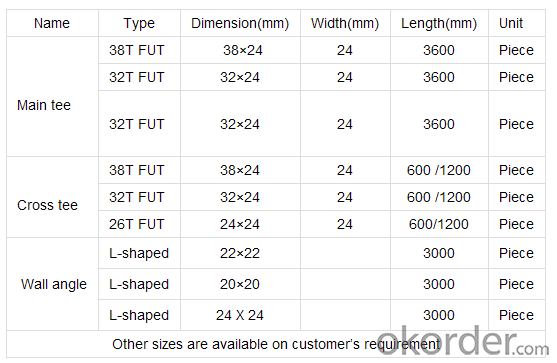

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q: Φ8 light steel keel boom is how much?

- Do pull the experiment to know the top burst out of the boom will not break off In the beam generally around 300KG

- Q: Code for construction of light steel keel gypsum board ceiling in decoration works

- Cover the panel before the installation of the keel and cover to be installed to check the plate, keel bottom to be flat, light holes, tuyere, probe, nozzle and other positions to stay out of keel, if the main keel will have to be reinforced, After the requirements of the panel can be installed, fixed panel nail cap to sink into the panel 0.5 ~ 1 mm and for rust treatment, after the paint putty embedded flat.

- Q: does anyone know where I can find clips to hang things from acoustic ceiling grids?

- ace hardware where i got some before

- Q: T-type light steel keel tb24 * 38 what does it mean

- T-type is not on the person, the width of 24mm, height 38mm is the T-type main keel

- Q: In the CAD 'light steel keel seal 18 PCT big core board posted 8 PCT car side gray paint glass' What is the meaning of this sentence? Request to say the details of the point yo.

- Light steel dragon skeleton to do 18mm large core board surface paste 8mm gray paint glass

- Q: It is good when the ceiling is light steel keel and wood keel

- In fact, the development of the ceiling process to the present, is not purely with wooden keel or light steel keel, and these two years have seen a lot of the combination of the way the ceiling. Wood keel easy to do modeling, light steel keel support strong, not easy to deformation, so now when the ceiling, in the need to shape the place with wooden keel, the other to do with the support of light steel keel is the most reasonable way.

- Q: What is the keel of the ceiling?

- If it is home improvement ceiling with ordinary light steel keel on the line, tooling, then it is recommended to use paint keel with mineral wool board.

- Q: Light steel keel ceiling models which

- Wall steel ceiling keel specifications and information decoration materials Light steel keel wall materials are 50, 75, 100, 150 and several other Light steel keel thickness ranging from 0.4mm to 2.0mm.

- Q: I would like to open a light steel keel processing plant do not know how good?

- The construction industry market demand is very large, as long as things are hard enough to do bad market. The beginning will inevitably encounter some problems, but do not experience the hardships and how could be successful. My house is being renovated, the decoration is really tired, but two months down to give me the feeling is that the real estate in China when the real estate chain of any industry will make money. Hope you firm your own ideas, bold to do it

- Q: Home decoration, the roof is a cement board, if the ceiling is light steel keel or better with a wooden keel better? Thank you

- If the hanging gypsum board to do paint, it is best wood keel, no gap. Light steel keel retractable screws have a gap, a long time, gypsum board splicing will crack.

Send your message to us

Wall Angle Ceiling Grid System EGT Suspension Ceiling Grid System EGT

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords