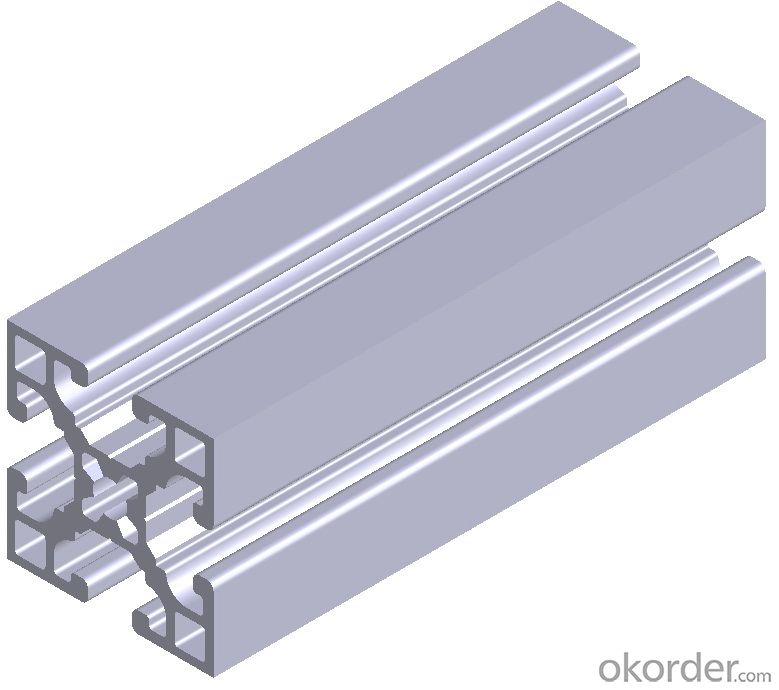

Structural Aluminum Extrusion Profiles - Aluminium S-Profile for Building Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium S-profile for Building Constructions Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium S-profile for Building Constructions:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of theAluminium S-profile for Building Constructions:

Aluminium S-profile for Building Constructions Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Tips for identifying aluminum profiles

- For the mechanical framework of aluminum on the market quality is not good, consumers can use a simple method to distinguish aluminum, so you use the time better.

- Q: This question asks about the various types of aluminum profiles that are utilized specifically for constructing wall frames.

- <p>Aluminum profiles for wall frames come in various types, each serving specific purposes. Common types include: 1) Structural profiles, which provide the main support and strength to the frame; 2) Cover profiles, used to conceal joints and fasteners, enhancing the aesthetic appeal; 3) Insulation profiles, designed to provide thermal insulation; 4) Glazing profiles, used to hold glass or other transparent materials in place; 5) Corner profiles, for joining two walls at a right angle; 6) Sealing profiles, to ensure weatherproofing and airtightness; and 7) Special profiles, tailored for unique architectural designs or specific functions. Each type is chosen based on the structural requirements, design aesthetics, and performance needs of the wall system.</p>

- Q: What are the different surface polishing options for aluminum profiles?

- Aluminum profiles offer various surface polishing options, each with its own shine and finish levels. These methods include mechanical polishing, chemical polishing, electrolytic polishing, and anodizing. Mechanical polishing involves using abrasives and polishing compounds to physically eliminate surface imperfections and achieve a smooth, reflective finish. This can be done manually or with automated machines. While it provides a high shine, it requires careful attention to detail and multiple steps. Chemical polishing, on the other hand, employs chemical solutions to dissolve a thin layer of aluminum, resulting in a smoother surface. It is often used for large-scale production due to its quick and uniform application, but it may not offer the same level of shine as mechanical polishing. Electrolytic polishing utilizes an electric current to eliminate surface imperfections and create a polished finish. By using the aluminum profile as an anode and a conductive material as the cathode, electrolytic polishing produces a mirror-like finish with excellent precision and uniformity. Although not a polishing method itself, anodizing is a commonly used surface treatment for aluminum profiles. It involves creating a protective oxide layer on the metal's surface through an electrochemical process. Anodizing enhances the appearance of profiles by providing a smooth, colored, or clear finish, while also improving their durability and resistance to corrosion. The choice of surface polishing option depends on factors such as the desired shine level, the complexity of the profile's design, and the intended application. It is essential to consider cost, time, and quality requirements when selecting the most suitable option, as each method has its advantages and limitations.

- Q: Can aluminum profiles be used for skylights?

- Yes, aluminum profiles can be used for skylights. Aluminum is a popular material choice for skylight frames due to its durability, strength, and resistance to corrosion. It is lightweight yet sturdy, making it suitable for supporting the weight of skylight glass while ensuring long-lasting performance. Additionally, aluminum profiles can be easily customized and shaped to meet specific design requirements, allowing for various skylight styles and sizes. The use of aluminum profiles in skylights also provides excellent thermal insulation properties, contributing to energy efficiency by reducing heat transfer and preventing condensation. Overall, aluminum profiles are a reliable and practical option for constructing skylights.

- Q: we recently entered a batch of aluminum billet, under the rain, billet oxidation, spray finished drawing after the profile off the skin, how to do

- Before treatment, not dealt with, must be dealt with before spraying, this situation.

- Q: Are aluminum profiles suitable for gym equipment?

- Indeed, gym equipment can be made using aluminum profiles. Aluminum, being both lightweight and durable, can endure rigorous use and offer exceptional structural support. Its remarkable strength-to-weight ratio renders it perfect for gym equipment, granting effortless maneuverability while retaining stability and durability. Moreover, aluminum is resistant to corrosion, making it apt for environments abundant in moisture or humidity, like gyms or fitness centers. The versatility of aluminum profiles further allows for the customization of gym equipment to suit precise needs and requirements. Overall, aluminum profiles present a plethora of advantages for gym equipment, establishing them as an appropriate selection for fitness facilities.

- Q: What are the advantages of using aluminum profiles in the aviation industry?

- There are several advantages of using aluminum profiles in the aviation industry. Firstly, aluminum is lightweight, which helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency and lower operating costs. Secondly, aluminum profiles offer excellent strength-to-weight ratio, providing structural integrity and durability to withstand the demanding conditions of aviation. Thirdly, aluminum is corrosion-resistant, making it ideal for withstanding the effects of moisture and other environmental elements. Additionally, aluminum profiles are easy to fabricate, allowing for efficient manufacturing processes and quicker turnaround times.

- Q: What is the terminology to explain the aluminum twist and bending and a sharp respectively.

- Curvature:1. longitudinal bending: the profile is placed on the platform, and when the weight is stable, the maximum gap between the bottom of the profile and the platform is measured along the length of the profile, that is, the longitudinal curvatureThe 2. longitudinal wave degree (or bend): the section on the platform, to achieve stability by self, the ruler will be 300mm long (or flat on the surface of the profile cutter) waves or hard along the length direction of a profile, profile measurement and rule (or ruler knife) between the maximum gap value that is, longitudinal wave degree (or bend).

- Q: What unique considerations or specifications are needed when utilizing aluminum profiles in cold weather conditions?

- <p>In cold climates, special requirements for using aluminum profiles include selecting materials with enhanced thermal performance to prevent condensation and frost. It's crucial to use aluminum profiles with appropriate thermal breaks to reduce heat loss. Additionally, consider using profiles with higher strength to withstand the contraction and expansion caused by temperature fluctuations. Protective coatings or finishes may be necessary to prevent corrosion from salt or other winter chemicals. Always consult with manufacturers for specific recommendations tailored to the climate conditions.</p>

- Q: I have a disinfection cabinet to cut off a piece of aluminum to install the control board, how to cut? What tool to cut?

- The use of wire saw can be sawed, if you cannot use a wire saw, it can only be used to drill holes along the need the position of the drill hole, finally use a tool to trim it to the edge.

Send your message to us

Structural Aluminum Extrusion Profiles - Aluminium S-Profile for Building Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords