Steel Round Bar S355J2G3 Forged Round Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel Round Bar S355J2G3 Forged Round Steel

Product Information:

1.S355J2G3 forged round bar

2.size:280*5300mm

3.ut:sep1921-84D/d

4.heatreatment:annealed

5.straightness:2mm/m

6.Process: EAF+LF+VD (ESR furnace for optional)

7.Delivery condition: Hot forged, Heat-treatment (Normalized / Annealed / Quenched / tempered), Rough machining

8.Technical Data: Chemical Composition, Physical Properties and Mechanical Testing according to the customer's requirement

9.Test: Ultrasonic and magnetic test according to customer' require(EN or ASME and so on).

Product Overviews:

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 | GB/SAE/JIS/DIN |

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

| Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

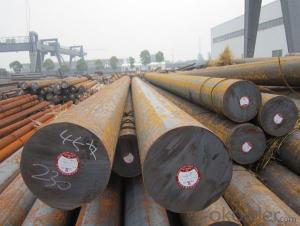

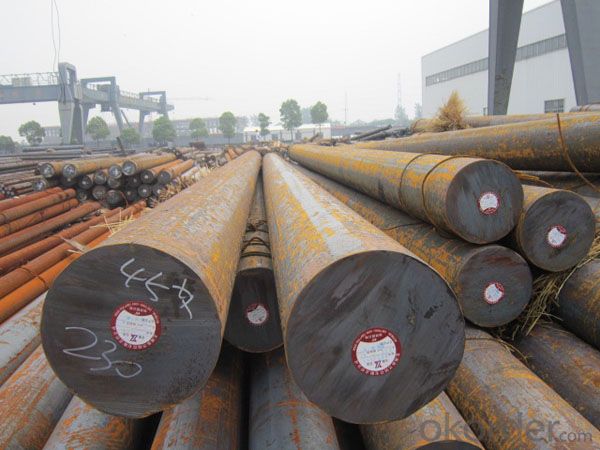

Product Show:

Our Advantages:

· Industry experience over 20 years.

· Shipment of goods -More than 70 countries worldwide.

· The most convenient transport and prompt delivery.

· Competitive price with best service.

· High technical production line with top quality products.

· High reputation based on best quality products.

With our experienced, enthusiastic and dynamic staffs, we assure to bring you the products with best quality, reasonable prices and good after-sales services under the motto: Friends First, Business After.

Communication, Experience, Expertise and Best efforts are our Promises to you.

- Q: How does special steel contribute to the weldability of products?

- The weldability of products is improved in various ways by special steel. Firstly, special steel is designed specifically to have enhanced weldability characteristics, making it easier for welders to join different pieces of steel. This is achieved by carefully controlling the chemical composition of the steel, ensuring that it contains the necessary alloying elements and impurity levels to promote good weldability. Secondly, special steel often has a lower carbon content compared to regular steel, reducing the likelihood of weld metal cracking. Carbon is known to increase the susceptibility to cracking during welding, so by decreasing the carbon content, special steel reduces this risk, resulting in a stronger and more durable weld joint. Furthermore, the weldability of special steel is improved by controlling the grain size and microstructure. Fine-grained steel exhibits better toughness and reduced brittleness, making it less prone to cracking during welding. Similarly, a well-controlled microstructure ensures a more uniform distribution of alloying elements, leading to improved mechanical properties and weldability. To further enhance its weldability, special steel often undergoes various heat treatment processes. Annealing, normalizing, or quenching and tempering can refine the microstructure, relieve residual stresses, and improve the toughness of the steel, all of which contribute to better weldability. In addition, special steel is carefully manufactured to have low levels of impurities, such as sulfur and phosphorus, which can negatively affect weldability. By minimizing these impurities, the steel can be welded without the formation of detrimental welding defects, ultimately improving the overall quality of the weld. In conclusion, special steel plays a crucial role in enhancing the weldability of products. Its carefully controlled chemical composition, reduced carbon content, controlled grain size and microstructure, as well as the application of heat treatments, all contribute to easier, stronger, and more reliable weld joints.

- Q: How is stainless tool steel used in the manufacturing of surgical instruments?

- Stainless tool steel is commonly used in the manufacturing of surgical instruments due to its exceptional properties such as corrosion resistance, high strength, and durability. This type of steel ensures that surgical instruments can withstand frequent sterilization processes without corroding or deteriorating. Additionally, stainless tool steel allows for precise shaping and sharpening of surgical instruments, ensuring their effectiveness and longevity in medical procedures.

- Q: Can special steel be used in the defense sector?

- Yes, special steel can be used in the defense sector. Special steel refers to alloys or compositions that are specifically designed to possess certain properties, such as high strength, hardness, resistance to corrosion, or heat resistance. These properties make special steel suitable for various defense applications, including the construction of armored vehicles, naval vessels, aircraft, and weaponry. In the defense sector, special steel can be used to manufacture components and structures that require exceptional strength and durability. For example, it can be used in the production of armor plates for tanks and armored vehicles, which need to withstand high impact and ballistic threats. Special steel can also be utilized in the construction of naval vessels, where it provides resistance to corrosion and enhances the overall structural integrity. Furthermore, special steel is crucial in the defense industry for the manufacturing of aircraft parts and weaponry. Aircraft components, such as landing gear, engine parts, and structural elements, require high-strength materials to ensure safe and reliable operation. Special steel alloys can provide the necessary strength and resistance to extreme conditions, such as high temperatures and pressures, making them ideal for these applications. Moreover, special steel can be used in the production of various types of weapons, including firearms and blades. Its excellent strength and hardness properties make it suitable for manufacturing gun barrels, bulletproof vests, and knives used by military personnel. In summary, special steel is highly valued in the defense sector due to its exceptional properties, including strength, hardness, corrosion resistance, and heat resistance. It finds extensive applications in the construction of armored vehicles, naval vessels, aircraft, and weaponry, ensuring the safety, durability, and effectiveness of military equipment.

- Q: Can special steel be used for electrical applications?

- Yes, special steel can be used for electrical applications. Special steel alloys, such as stainless steel or electrical-grade steels, are often used in electrical applications due to their excellent electrical conductivity, resistance to corrosion, and high strength properties. These steels are commonly utilized in the manufacturing of electrical components, wiring, transformers, and various electrical equipment.

- Q: What are the different forming techniques used for special steel?

- Some of the different forming techniques used for special steel include rolling, forging, extrusion, and casting.

- Q: How does special steel contribute to the construction sector?

- Special steel plays a crucial role in the construction sector by offering a wide range of benefits that contribute to the overall quality, durability, and safety of structures. Firstly, special steel possesses exceptional strength and toughness, making it an ideal material for constructing high-rise buildings, bridges, and other infrastructure projects. Its high tensile strength allows for the creation of lighter and more slender structures, reducing material costs and enabling architects to design innovative and aesthetically pleasing buildings. Moreover, special steel is highly resistant to corrosion, which is particularly important in construction projects located in harsh environments, such as coastal areas or industrial zones. This resistance ensures that structures built with special steel have a longer lifespan and require less maintenance, resulting in significant cost savings over time. Additionally, its resistance to fire and extreme temperatures makes it an essential material for fire-resistant structures and critical components in buildings, ensuring the safety of occupants. Special steel also offers excellent ductility and weldability, allowing for seamless integration with other construction materials and facilitating efficient assembly processes. Its versatility enables it to be used in various structural elements, such as beams, columns, and reinforcement bars, providing stability and structural integrity to buildings, as well as improving seismic performance. Furthermore, the use of special steel in construction aligns with sustainability goals. It is a recyclable material that can be reused without compromising its properties, reducing the environmental impact of the construction sector. Furthermore, its lighter weight compared to traditional materials minimizes the carbon footprint associated with transportation and installation. In summary, special steel contributes significantly to the construction sector by providing strength, durability, fire resistance, corrosion resistance, and versatility. Its use enables the construction of safer, more cost-effective, and environmentally-friendly structures, thereby enhancing the overall quality and sustainability of the built environment.

- Q: How does special steel perform in high-velocity impact conditions?

- Special steel is specifically designed to perform well in high-velocity impact conditions. It possesses exceptional strength and toughness, allowing it to withstand the intense forces exerted during such impacts. The unique composition and heat treatment of special steel enable it to absorb and distribute the energy generated by the impact, minimizing deformation and potential damage. Overall, special steel demonstrates excellent performance and reliability in high-velocity impact conditions.

- Q: How does special steel contribute to the aerospace racing industry?

- The aerospace racing industry heavily relies on special steel due to its superior strength, durability, and performance characteristics, which are essential for the demanding conditions and requirements of high-speed racing. One of the primary contributions of special steel to the aerospace racing industry lies in its capacity to withstand extreme temperatures and pressures. Special steel alloys, such as nickel-based superalloys, are specifically designed to maintain their mechanical properties even under high temperatures. This makes them highly suitable for withstanding the intense heat generated during racing. These alloys also exhibit exceptional creep resistance, enabling the components to endure prolonged exposure to elevated temperatures without experiencing any deformation or failure. Furthermore, special steel alloys possess remarkable strength-to-weight ratios, giving the aerospace racing industry a competitive advantage. The high strength of these alloys allows for the design and construction of lighter and more efficient racing components, including engine parts, landing gears, and structural elements. As a result, the overall weight of the aircraft is reduced, thereby enhancing its performance and speed while ensuring structural integrity and safety. In addition, special steel offers excellent corrosion resistance, which is crucial in the aerospace racing industry. The harsh conditions encountered during racing, such as exposure to moisture, chemicals, and atmospheric elements, can lead to corrosion and deterioration of vital components. However, special steel alloys, such as stainless steel, demonstrate high resistance to corrosion, guaranteeing the longevity and reliability of racing aircraft. Moreover, the unique metallurgical properties of special steel, such as high fatigue and fracture resistance, contribute significantly to the safety and reliability of the aerospace racing industry. The high fatigue strength of these alloys allows them to withstand repeated loading and unloading cycles without developing cracks or experiencing failures. This is particularly important in high-speed racing, where components undergo significant stress and strain. Additionally, special steel's exceptional fracture toughness ensures that any potential cracks or flaws do not propagate catastrophically, minimizing the risk of catastrophic failures during racing. In conclusion, special steel plays a critical role in the aerospace racing industry by providing superior strength, durability, and performance characteristics. Its ability to withstand extreme temperatures, offer excellent strength-to-weight ratios, resist corrosion, and exhibit high fatigue and fracture resistance make it an indispensable material for constructing racing aircraft components. Ultimately, the use of special steel in the aerospace racing industry enhances the performance, speed, safety, and reliability of racing aircraft, pushing the boundaries of aerospace technology and propelling the industry forward.

- Q: How does special steel contribute to the electrical conductivity of products?

- Special steel can contribute to the electrical conductivity of products in several ways. Firstly, special steel alloys can be formulated with specific chemical compositions that enhance their electrical conductivity. For example, adding elements such as copper, silver, or nickel to the steel can increase its electrical conductivity by providing more pathways for the flow of electric current. Additionally, the microstructure of special steel can be manipulated to improve electrical conductivity. By controlling the grain size and orientation of the steel, it is possible to reduce the resistance to the flow of electrons, thereby increasing the overall conductivity of the material. Furthermore, special steel can be heat treated or subjected to other processes to enhance its electrical conductivity. Heat treatment techniques like annealing or tempering can help to remove impurities and improve the crystal structure of the steel, resulting in improved electrical conductivity. Moreover, special steel can also be designed to have low magnetic permeability, which means it exhibits less resistance to the flow of magnetic fields. This property is beneficial for applications where electromagnetic interference needs to be minimized, such as in electrical connectors or transformers. In summary, special steel contributes to the electrical conductivity of products through various means, including chemical composition, microstructural control, heat treatment, and low magnetic permeability. By optimizing these factors, special steel can significantly enhance the performance of electrical components and systems.

- Q: How does special steel contribute to the defense sector?

- Special steel contributes to the defense sector in several ways. Firstly, it is used in the production of military vehicles, aircraft, and naval vessels, providing strength, durability, and resistance to extreme conditions. Secondly, special steel is utilized in the manufacturing of ballistic armor and bulletproof vests, offering enhanced protection to military personnel. Additionally, it is used in the construction of weaponry, such as firearms and artillery, ensuring reliability and precision. Overall, special steel plays a crucial role in enhancing the capabilities and safety of defense equipment and personnel.

Send your message to us

Steel Round Bar S355J2G3 Forged Round Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords