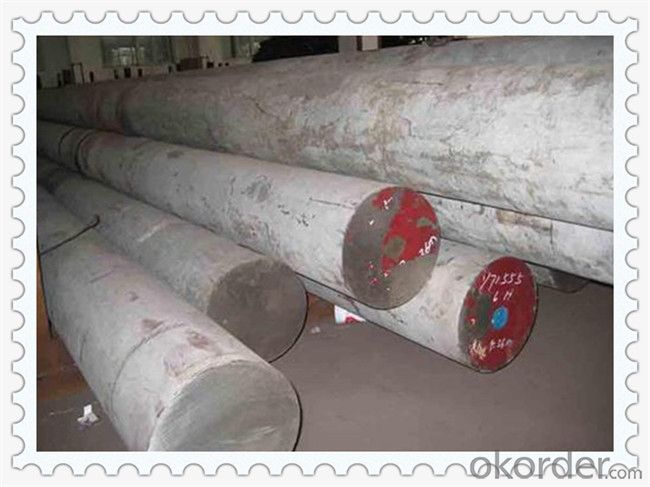

Q345B st52-3 Cr50 S355JR Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Q345B st52-3 Cr50 S355JR Steel Round Bar

1. Grade:Q345B, Q235B, SS400, HRB335, ST52-3

2. Hot-rolling

3. DIa:10-300mm

4. MOQ:20tons

5. Chemical and physical properties

Grade | C | Mn | Si | P | S | Yield Point(Mpa) | Tensile Stregth(Mpa) | Elongation (%) |

ST52-3 | ≤0.22 | ≤1.60 | ≤0.60 | ≤0.040 | ≤0.040 | ≥325 | 490 630 | ≥18 |

HRB335 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | ≥335 | ≥490 | ≥16 |

6.Size Tolerance

Length tolerance: +100mm/-0mm

Side length tolerance: +/-2mm

Straightness: max 6mm/m

The mill test certificate shall show the chemical composition, and it is guaranteed that the chemical composition shall be within the limit stipulated in the contract.

We are engaged to offer wide range of steel products: steel round bar, square steel, such

as SS400B, S20C, S45C, Ck45, SAE1020B, SAE1045B, SAE4140, SAE4150, SAE4340,

SAE8620, 42CrMo4, 15B36Cr, S50C, S65C. 20Cr,40Cr.The diameter ranging from 20mm

to 300mm. Hot-rolled/forged/cold drawn.

- Q: How are steel round bars used in the manufacturing of fasteners and bolts?

- Steel round bars are commonly used in the manufacturing of fasteners and bolts due to their inherent strength and durability. These round bars serve as the primary material for producing the shaft or body of the fastener or bolt. The manufacturing process typically involves several steps. First, the steel round bars are cut into the desired length, based on the specifications of the fastener or bolt being produced. Next, the bars are heated to a specific temperature to soften the steel, making it easier to shape. Once the bars have been heated, they are placed in a machine called a thread roller. This machine uses a series of hardened steel dies to form the threads onto the surface of the round bar. The dies press against the rotating bar, creating the spiral shape of the threads. This threading process is crucial as it allows the fastener or bolt to securely attach to other components or structures. After the threads have been formed, the round bars are then cut to the final required length for the fastener or bolt. This step ensures that the fastener or bolt is of the correct size and will fit the intended application. Finally, the finished round bars are further processed to add any necessary surface treatments or coatings. This may include processes such as galvanizing or applying a corrosion-resistant coating to protect the fastener or bolt from environmental factors that could affect its performance. In summary, steel round bars play a crucial role in the manufacturing of fasteners and bolts. They are used as the main material for the shaft or body of the fastener or bolt, providing the necessary strength and durability. Through various manufacturing processes such as cutting, heating, threading, and surface treatments, these round bars are transformed into high-quality fasteners and bolts that are essential components in a wide range of industries and applications.

- Q: Can steel round bars be used in the manufacturing of gears?

- Certainly, gears can utilize steel round bars in their manufacturing process. The utilization of steel round bars is quite common in gear manufacturing given their remarkable attributes such as formidable strength, long-lasting durability, and remarkable resistance to wear and tear. The rounded shape of these bars allows for effortless machining and molding into the desired gear design. Furthermore, steel round bars possess exceptional mechanical properties, including impressive tensile strength and commendable resistance to fatigue, which are crucial for gears that encounter heavy loads and repetitive movements. Additionally, steel round bars can undergo heat treatment to further enhance their hardness and toughness, rendering them ideal for demanding gear applications. All in all, steel round bars are a highly favored option in gear manufacturing due to their adaptability and dependability.

- Q: Can steel round bars be used in the production of musical instruments?

- Yes, steel round bars can be used in the production of musical instruments. Steel is a versatile material that offers a range of desirable properties such as strength, durability, and resonance. While wood is commonly used in the construction of musical instruments, steel can be employed in certain applications to enhance the instrument's sound and performance. Steel round bars can be utilized in the manufacturing of various components, such as keys or valves for wind instruments like saxophones or trumpets. These bars can also be used to create the internal support structures in instruments like guitars or cellos, providing stability and enhancing tonal qualities. Additionally, steel round bars can be used in the construction of percussion instruments such as steel drums or xylophones, where their strong and resonant properties are highly desirable. Overall, while steel is not as commonly used as wood in musical instrument production, it can certainly be employed in specific cases to achieve desired sound characteristics and structural integrity.

- Q: What are the advantages of using maraging steel round bars?

- There are several advantages of using maraging steel round bars in various applications. 1. High strength: Maraging steel round bars have an exceptionally high strength-to-weight ratio, making them ideal for applications where strength is crucial. These bars can withstand high stress and load-bearing conditions without deformation or failure, ensuring structural integrity. 2. Superior toughness: Maraging steel round bars exhibit excellent toughness, which means they can absorb a significant amount of energy before fracturing. This property makes them highly resistant to cracking or breaking, even under extreme conditions, enhancing their durability and reliability. 3. Corrosion resistance: Maraging steel round bars are known for their exceptional corrosion resistance. They are less susceptible to rust and oxidation compared to other types of steel, making them suitable for applications in harsh environments or where exposure to moisture or chemicals is a concern. This corrosion resistance helps prolong the lifespan of the bars and reduces maintenance costs. 4. Machinability: Maraging steel round bars are relatively easy to machine, despite their high strength and hardness. They can be readily shaped, drilled, and cut into various forms and sizes, allowing for versatile applications across different industries. This ease of machining saves time and effort during the manufacturing process. 5. Heat treatability: Maraging steel round bars have excellent heat treatability, meaning they can be hardened and tempered to further improve their mechanical properties. This flexibility in heat treatment allows for customization to meet specific project requirements, such as achieving desired hardness levels or enhancing specific characteristics like wear resistance or toughness. 6. Aerospace and defense applications: Maraging steel round bars are widely used in aerospace and defense industries due to their exceptional strength, toughness, and corrosion resistance. They are commonly employed in the manufacturing of critical components like landing gear, missile casings, and aircraft structures, where reliability and performance are of utmost importance. Overall, the advantages of using maraging steel round bars include their high strength, superior toughness, corrosion resistance, machinability, heat treatability, and suitability for aerospace and defense applications. These properties make them a preferred choice for various demanding industries and ensure optimal performance and longevity in critical applications.

- Q: Can steel round bars be used in the manufacturing industry?

- Certainly! In the manufacturing industry, steel round bars find extensive utility. These bars exhibit great versatility and are extensively employed across diverse manufacturing processes. Machining, forging, welding, and fabrication all benefit from their usage, facilitating the creation of an array of products, including machinery parts, tools, automotive components, construction materials, and more. These round bars boast exceptional robustness, durability, and remarkable wear resistance, rendering them highly suitable for arduous manufacturing applications. Furthermore, manufacturers can select from a range of grades and sizes, enabling them to opt for the most appropriate option tailored to their specific needs.

- Q: What are the properties of steel round bars?

- Steel round bars have several properties that make them highly desirable for a wide range of applications. Firstly, they possess exceptional strength and durability, making them suitable for load-bearing structures and heavy-duty machinery. Additionally, steel round bars exhibit excellent corrosion resistance, allowing them to withstand harsh environmental conditions without compromising their integrity. They also have a high melting point and can withstand extreme temperatures, making them ideal for applications that involve heat or fire. Furthermore, steel round bars can be easily machined, welded, and fabricated, providing flexibility in design and construction processes. Lastly, they offer good dimensional stability and precise tolerances, ensuring consistent performance and reliability in various industrial and construction settings.

- Q: Can steel round bars be used for making automotive suspension systems?

- Yes, steel round bars can be used for making automotive suspension systems. Steel round bars are commonly used in the manufacturing of suspension components such as control arms, sway bars, and torsion bars due to their high strength, durability, and ability to withstand heavy loads and vibrations.

- Q: What is the difference between a smooth and a precision ground steel round bar?

- A smooth steel round bar refers to a steel rod that has a plain surface without any specific surface treatment or finishing process. It is typically produced through hot rolling or cold drawing methods, resulting in a basic cylindrical shape with a relatively rough surface texture. Smooth steel round bars are commonly used in various applications where a smooth exterior finish is not a critical requirement. On the other hand, a precision ground steel round bar undergoes an additional manufacturing process to achieve a more precise and refined surface finish. The precision grinding process involves removing any imperfections or irregularities from the surface of the steel rod, resulting in a highly smooth and polished finish. This process ensures that the diameter of the round bar remains consistent along its length and that the surface has a superior level of finish and accuracy. Precision ground steel round bars are widely used in applications that demand tight tolerances, precision machining, or where a smooth and polished surface is essential. Industries such as aerospace, automotive, tooling, and manufacturing often rely on precision ground steel round bars for their high-quality surface finish, dimensional accuracy, and reliable performance. In summary, the main difference between a smooth and a precision ground steel round bar lies in the surface finish and level of precision achieved. While a smooth steel round bar has a basic, rough surface texture and is suitable for general applications, a precision ground steel round bar undergoes additional grinding processes to achieve a highly smooth, polished, and accurate surface finish, making it ideal for applications requiring tight tolerances and precision machining.

- Q: How do you calculate the weight of a steel round bar based on its length and diameter?

- To calculate the weight of a steel round bar based on its length and diameter, you can use the following equation: Weight = (π/4) x (Diameter^2) x Length x Density Here, π represents the mathematical constant pi (approximately 3.14159), Diameter is the measurement of the steel round bar across its widest point, Length is the overall length of the bar, and Density is the density of steel, which is typically around 7850 kilograms per cubic meter. To calculate the weight, first square the diameter, then multiply it by the length and density. Finally, multiply the result by π/4 to obtain the weight of the steel round bar in the desired units (typically kilograms or pounds). It's important to note that this equation assumes the steel round bar is a solid cylinder with a uniform diameter. If the bar has any variations or irregularities, the weight calculated using this equation may not be entirely accurate.

- Q: How do steel round bars compare to stainless steel round bars?

- Steel round bars and stainless steel round bars differ in their composition, making them suitable for various applications. The composition of steel mainly consists of iron with small amounts of carbon and other elements, whereas stainless steel is an alloy composed of iron, chromium, and often other elements like nickel or molybdenum. This unique composition gives stainless steel its distinctive properties, such as corrosion resistance. Both steel and stainless steel round bars can be manufactured to have high tensile strength. However, stainless steel generally has higher tensile strength compared to regular steel, making it more suitable for applications requiring additional strength and durability. Another significant difference lies in their resistance to corrosion. Stainless steel round bars have excellent corrosion resistance due to the presence of chromium in their composition, making them ideal for applications exposed to moisture, chemicals, or other corrosive environments. On the other hand, steel round bars are more prone to rust and corrosion and may need additional protective coatings in such environments. In terms of cost, steel round bars are generally more affordable compared to stainless steel round bars. The higher cost of stainless steel is attributed to its unique properties and the additional alloying elements required in its production. Both steel and stainless steel round bars have advantages and specific applications. Steel round bars are commonly used in construction, manufacturing, and general-purpose applications where corrosion resistance is not a primary concern. In contrast, stainless steel round bars find extensive use in industries such as food processing, chemical processing, medical equipment, and marine applications where corrosion resistance is crucial. In conclusion, the choice between steel round bars and stainless steel round bars depends on the specific requirements of the application. Steel round bars are more cost-effective but may require additional corrosion protection, while stainless steel round bars offer superior corrosion resistance and strength.

Send your message to us

Q345B st52-3 Cr50 S355JR Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords