Steel roofing sheets cold rolled free samples

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 52691 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold rolled steel coil/sheet is one of the main raw material of furniture automotive parts, industry steel parts, building construction, raw

material of color painted coil. Meanwhile we can provide full hard raw material they are properly used in the high strength construction.

Because cold rolled steel sheet is prone to rusting, standard practice is to apply a rust-preventative oil at the exit end of the temper mill (the last processing step). Rust-preventative oils are different than forming lubricants in that they contain special corrosion-inhibiting additions. In addition to the oil, Curtis Steel maintains clean, dry environments in climate controlled warehouses at all

its facilities to ensure our coils and sheets arrive to you in prime condition.

Cold rolled sheet products have been available for many, many years, and have been successfully used for a multitude of

applications. Today's cold rolled sheet products are much improved over those used in the past. They offer better control of

thickness, shape, width, surface finish, and other special quality features that compliment the emerging need for highly engineered

end use applications.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

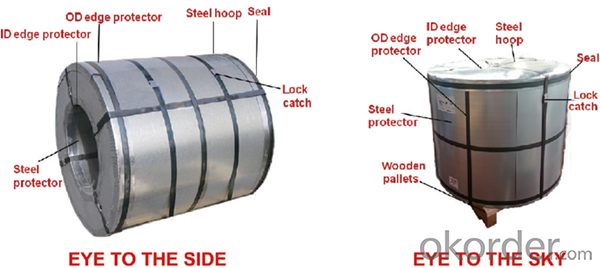

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will

provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing

as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: What is the minimum thickness of a steel sheet?

- The minimum thickness of a steel sheet relies on a variety of factors, including the specific grade of steel used, the intended application, and the manufacturing process. However, steel sheets can generally be manufactured with thicknesses ranging from 0.4 millimeters (0.016 inches) to several millimeters. It should be noted that thinner steel sheets are typically utilized for flexible and lightweight applications, such as automotive body panels or electrical enclosures, while thicker sheets are employed for structural purposes, like construction materials or heavy machinery components. Ultimately, the specific needs of the project or application determine the minimum thickness of the steel sheet.

- Q: What are the rental costs for steel sheet piles?

- The utility model has the advantages of high strength, easy to break into the hard soil layer; construction in deep water, if necessary with the inclined support into a cage. The utility model has the advantages of good waterproof performance, forming a cofferdam with various shapes according to requirements and repeated use for many times; therefore, the utility model has wide application.

- Q: What are the standard dimensions for steel sheets?

- The specific type and grade of steel being used can cause variation in the standard dimensions for steel sheets. Generally, steel sheets are found in standard sizes of 4 feet by 8 feet or 4 feet by 10 feet. These dimensions are widely used in the construction industry and can be easily obtained from steel suppliers. Moreover, steel sheets can be tailored to specific dimensions to meet the requirements of a particular project. It is crucial to seek guidance from a steel supplier or manufacturer to ascertain the precise dimensions available for the desired type of steel sheet.

- Q: Are the steel sheets suitable for food-grade applications?

- Yes, steel sheets are suitable for food-grade applications.

- Q: What is the average weight of a steel sheet per square meter?

- The average weight of a steel sheet per square meter can vary depending on the thickness and type of steel being used. However, a general estimate for mild steel sheets is around 7.85 kilograms per square meter. It is important to note that this weight can vary slightly based on the specific composition of the steel and any additional coatings or treatments applied to the sheet.

- Q: Are steel sheets suitable for construction applications?

- Yes, steel sheets are highly suitable for construction applications. Steel is known for its strength, durability, and versatility, making it a popular choice in the construction industry. Steel sheets are commonly used in various applications, such as roofing, flooring, wall panels, structural frames, and cladding. They offer excellent load-bearing capacity, allowing for the construction of large and sturdy structures. Steel sheets are also fire-resistant, which enhances the safety of the building. Additionally, steel is resistant to pests, rot, and corrosion, ensuring a longer lifespan for the construction. Furthermore, steel sheets can be easily fabricated and customized to fit different construction needs, making them a cost-effective and efficient option. Overall, steel sheets are highly suitable for construction applications due to their strength, durability, versatility, and numerous other beneficial properties.

- Q: How do steel sheets perform in terms of electrical resistance?

- Steel sheets typically have relatively high electrical resistance compared to other materials. This means that they do not conduct electricity as easily as metals like copper or aluminum. The electrical resistance of steel sheets can vary depending on factors such as the composition and thickness of the sheet. In general, steel sheets are considered to be a poor conductor of electricity. However, it is important to note that electrical resistance can be reduced by applying certain coatings or treatments to the steel surface.

- Q: What are the different methods of protecting steel sheets from scratches?

- There are several methods of protecting steel sheets from scratches. One common method is applying a protective coating or paint on the surface of the steel sheet. This coating acts as a barrier and prevents scratches from occurring. Another method is using a temporary protective film or tape on the steel sheet. This film or tape can be easily applied and removed, providing a temporary safeguard against scratches. Additionally, using padded or protective packaging during transportation or storage can help prevent scratches. Implementing proper handling and storage procedures, such as using non-abrasive materials and avoiding stacking or sliding steel sheets, can also minimize the risk of scratches.

- Q: Bathroom washing machine, galvanized steel and color steel which good?

- Relatively little better than plastic, zinc impregnation with the color of teaching should be better, but also with the time of production process and bathroom moisture relationship

- Q: What are the different types of steel sheet coatings?

- In the market, there exists a variety of steel sheet coatings, each possessing its own unique properties and advantages. Some of the most commonly utilized types are as follows: 1. Galvanized Coating: This coating is extensively employed for steel sheets due to its exceptional corrosion resistance and ability to prevent rust. It involves the application of a zinc layer onto the steel surface. Galvanized coatings find widespread use in outdoor applications such as roofing, fencing, and automotive parts. 2. Galvannealed Coating: Similar to galvanized coating, galvannealed coating also entails the application of a zinc layer onto the steel surface. However, in this process, the coated steel undergoes a high-temperature annealing process, resulting in the formation of an iron-zinc alloy coating. This type of coating offers improved paintability and weldability, making it ideal for applications that require subsequent painting or welding. 3. Aluminized Coating: Aluminized coatings involve the application of an aluminum layer onto the steel surface. This offers exceptional heat resistance and corrosion resistance, making it suitable for applications involving high temperatures, such as exhaust systems and ovens. Aluminized coatings also possess good reflectivity properties, which make them valuable for reflective insulation applications. 4. Organic Coatings: Several organic coatings, including epoxy, polyester, and polyurethane coatings, are available for steel sheets. These coatings are typically applied as paints or powder coatings and provide a protective layer that enhances the durability and appearance of the steel. Organic coatings can be tailored to offer specific properties, such as UV resistance, chemical resistance, or decorative finishes. 5. Tin Coating: Tin coatings are commonly utilized in the food packaging industry. They create a barrier between the steel sheet and the food product, preventing any interactions that could compromise the quality or safety of the food. 6. Other Specialty Coatings: Several other specialty coatings are available for specific applications. These include zinc-nickel coatings, which offer enhanced corrosion resistance, and ceramic coatings, which provide high-temperature resistance and excellent electrical insulation properties. In summary, the choice of steel sheet coating depends on the specific requirements of the application, such as corrosion resistance, heat resistance, or aesthetic appeal. It is crucial to carefully evaluate the properties of each coating type to ensure optimal performance and longevity of the steel sheet in its intended use.

Send your message to us

Steel roofing sheets cold rolled free samples

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 52691 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords