Steel Rebar, Deformed Steel Bar, Iron Rods for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel rebar, Deformed Steel Bar, Iron Rods for Construction

Product information

1. Produce Standard: GB, AISI, ASTM, SAE, EN, BS, DIN, JIS

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment: Normalized / Annealed / Quenched+Tempered

4. Quality assurance: All order we can received third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product detail

Deformed Steel

1) Product name: Deformed Steel Bar

2) Standard and grade: a) GB1499-98 HRB335,HRB400,HRB500 b)BS4449-1997 GR460

3) Diameter: 8mm; 10mm; 12mm;14mm; 16mm;18mm; 20mm; 22mm; 25mm; 28mm; 30mm; 32mm; 40mm;

4) Length: 9m, 12m

5) Packing: Mill standard export packing in bundles, 2tons/bundle or 2tons/coil.

6) Country of Origin :China

7) Applications:The products are widely used in construction, road, machinery processing, and welding fields.

8)Delivery Time :Within 20 days.

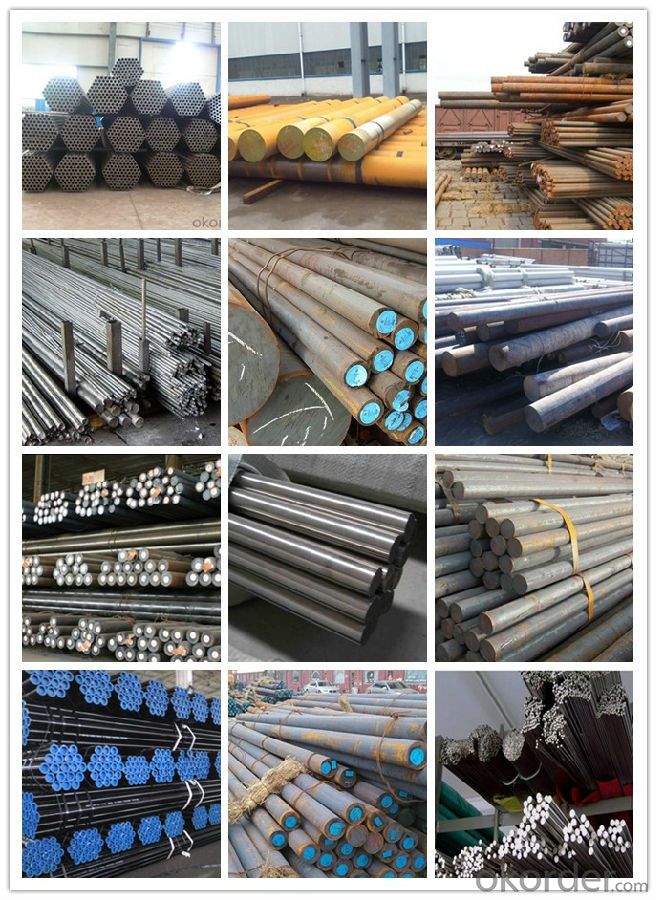

Product show

Work shop

Our Services

* Welcome to contact us with your detailed inquiry, you will be replied within 24 hours.

* You are promised to obtain the best quality, price and service.

* We'd like to provide samples for your confirm.

- Q: What are the main applications of special steel in the pharmaceutical industry?

- Special steel is widely used in the pharmaceutical industry for various applications. One of the main applications is in the manufacturing of high-quality equipment such as tanks, vessels, and pipes that are required for the storage and transportation of pharmaceutical products. Special steel is preferred due to its corrosion resistance, durability, and ability to maintain product purity. Additionally, special steel is utilized in the production of precision tools and instruments used in pharmaceutical research, development, and quality control processes. Moreover, special steel is essential in the construction of cleanrooms and controlled environments, ensuring the hygienic and sterile conditions required in pharmaceutical manufacturing.

- Q: What are the specific requirements for special steel used in the nuclear fuel industry?

- The specific requirements for special steel used in the nuclear fuel industry are stringent and demanding. These requirements are necessary to ensure the safety and reliability of nuclear power plants. Here are some of the key specifications for special steel used in this industry: 1. High temperature resistance: Special steel used in the nuclear fuel industry must be able to withstand high temperatures without losing its structural integrity. This is crucial as nuclear reactors generate extreme heat during operation. 2. Corrosion resistance: Nuclear fuel environments can be highly corrosive due to the presence of hot and pressurized water, radiation, and chemical reactions. Special steel used in the industry must have exceptional corrosion resistance to prevent degradation and maintain safety. 3. Radiation resistance: The nuclear fuel industry involves exposure to radiation. Special steel needs to have excellent resistance to radiation damage and embrittlement to ensure long-term structural integrity and prevent any risk of failure. 4. High strength and toughness: Special steel used in the nuclear fuel industry should possess high strength and toughness to withstand the extreme conditions experienced within a nuclear reactor. This ensures that the steel can withstand the pressure and stress exerted on it during reactor operation. 5. Low neutron absorption: Neutron absorption is a critical factor in nuclear reactors. Special steel used in the industry should have low neutron absorption properties to prevent interference with the nuclear reactions and to maintain reactor efficiency. 6. Strict quality control and traceability: The manufacturing and fabrication of special steel for the nuclear fuel industry must adhere to stringent quality control procedures to ensure consistency and reliability. Traceability is also crucial to identify the origin and history of the steel, allowing for comprehensive inspections and assessments. Meeting these specific requirements is essential for the safe and efficient operation of nuclear power plants. Special steel used in the nuclear fuel industry must undergo rigorous testing, certification, and quality control processes to ensure its compliance with these stringent specifications.

- Q: What are the factors that affect the wear resistance of special steel?

- The factors that affect the wear resistance of special steel include the composition of the steel, the hardness of the steel, the presence of carbides or other strengthening elements, the microstructure of the steel, the presence of surface treatments or coatings, the contact load or pressure applied to the steel, the sliding speed or velocity of the contact, the temperature at which the steel is operating, and the presence of any abrasive or corrosive media.

- Q: How does special steel enhance the durability of products?

- Special steel enhances the durability of products by providing them with superior strength, hardness, and resistance to corrosion and wear. Its unique composition and manufacturing processes result in a material that can withstand high pressure, extreme temperatures, and harsh environments, making it ideal for applications where regular steel would fail. This enhanced durability ultimately leads to longer product lifespans, increased reliability, and reduced maintenance costs.

- Q: How does special steel contribute to the renewable energy aftermarket industry?

- Special steel plays a crucial role in the renewable energy aftermarket industry by enhancing the efficiency, durability, and cost-effectiveness of renewable energy systems. One of the primary applications of special steel in this industry is in the manufacturing of wind turbine components. Wind turbines require high-strength and corrosion-resistant materials to withstand the harsh environmental conditions and generate electricity efficiently. Special steel alloys, such as high-strength low-alloy (HSLA) steel and stainless steel, offer superior mechanical properties, fatigue resistance, and excellent corrosion resistance, making them ideal for wind turbine tower structures, rotor blades, and other critical components. By using special steel in wind turbine manufacturing, the renewable energy aftermarket industry can benefit from increased turbine lifespan, reduced maintenance costs, and improved energy output. The strength and durability of special steel enable taller and larger wind turbine towers, allowing for the installation of turbines in areas with lower wind speeds. This expansion of suitable locations helps to maximize the energy production potential, making wind energy a more viable and widespread renewable energy source. Furthermore, special steel also contributes to the renewable energy aftermarket industry through its application in solar power systems. Solar panels require robust mounting structures to support the weight of the panels, withstand wind and snow loads, and ensure optimal sun exposure. Special steel, with its high strength-to-weight ratio and corrosion resistance, is commonly used in these mounting structures, providing long-lasting and reliable support for solar panels. In addition to wind and solar energy, special steel finds applications in other renewable energy systems such as hydroelectric power plants and geothermal systems. These industries benefit from the corrosion resistance and resistance to extreme temperatures offered by special steel, ensuring the longevity and efficiency of the equipment. Overall, special steel significantly contributes to the renewable energy aftermarket industry by enabling the production of reliable, durable, and efficient renewable energy systems. Through its use in wind turbines, solar panels, and other renewable energy technologies, special steel helps to enhance the performance and longevity of these systems, ultimately driving the growth and adoption of renewable energy sources worldwide.

- Q: How does special steel withstand high temperatures?

- Special steel is able to withstand high temperatures due to its unique composition and manufacturing process. It is typically alloyed with elements such as chromium, nickel, and molybdenum, which enhance its heat resistance properties. These alloying elements form stable oxides on the surface of the steel, creating a protective layer that prevents oxidation and corrosion at high temperatures. Additionally, special steel undergoes heat treatment processes like quenching and tempering, which further enhance its strength and ability to retain its structural integrity under extreme heat conditions.

- Q: What are the common grades of special steel?

- The common grades of special steel include stainless steel grades such as 304, 316, and 430, as well as tool steel grades like D2, A2, and O1. Other common grades include high-speed steel (HSS), alloy steel grades like 4140 and 4340, and maraging steel grades such as 250 and 300.

- Q: Can special steel be used in railway applications?

- Railway applications often utilize special steel, which is also referred to as alloy steel or high-strength steel. This type of steel possesses distinct characteristics that make it suitable for a wide range of demanding applications, including railways. Its exceptional strength, durability, and resistance to wear make it an ideal choice for railway components that endure high loads, vibrations, and extreme conditions. In the realm of railway applications, special steel is commonly employed in the manufacturing of rails, wheels, axles, and other crucial components. Rails crafted from special steel have the ability to handle heavy train traffic while providing a smooth and stable ride, all the while resisting wear and deformation. Special steel wheels and axles offer remarkable strength and toughness, ensuring safe and dependable operation even under heavy loads and high-speed conditions. Furthermore, special steel is frequently utilized in the construction of railway bridges, tunnels, and other infrastructure projects. Its exceptional strength and resistance to corrosion and fatigue make it suitable for supporting heavy trains and withstanding the environmental challenges associated with railway construction. Moreover, the utilization of special steel in railway applications can result in cost savings and efficiency improvements. Its high durability and wear resistance minimize the need for frequent maintenance and replacement, leading to reduced maintenance costs and an extended service life for railway components. In conclusion, special steel possesses the necessary strength, durability, and performance required for railway applications. Its unique properties make it an ideal choice for ensuring the safety, reliability, and efficiency of rail transportation systems.

- Q: Can special steel be used in the computer manufacturing industry?

- Yes, special steel can be used in the computer manufacturing industry. It is commonly used for various applications such as computer casings, hard drive components, and heat sinks due to its strength, durability, and thermal conductivity properties.

- Q: How does special steel contribute to the defense industry?

- Special steel contributes to the defense industry in various ways. Its exceptional strength, durability, and resistance to corrosion make it an ideal material for manufacturing military equipment, such as tanks, submarines, and aircraft carriers. Special steel is also used in the production of firearms, missiles, and armored vehicles, providing enhanced protection and performance capabilities. Additionally, its heat resistance and ability to withstand extreme temperatures make it suitable for crafting jet engines and other critical components used in military aircraft. Overall, special steel plays a crucial role in ensuring the reliability, safety, and effectiveness of defense equipment.

Send your message to us

Steel Rebar, Deformed Steel Bar, Iron Rods for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords