Steel Products From China Stainless Steel 304

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Technical notes:

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

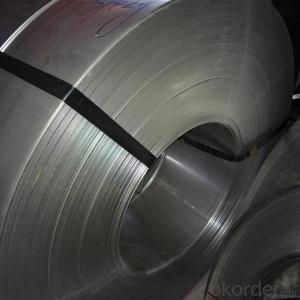

Detail picture for Stainless Steel Coils/Sheets

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Can stainless steel sheets be used for decorative purposes?

- Yes, stainless steel sheets can definitely be used for decorative purposes. Stainless steel is known for its sleek and modern appearance, making it a popular choice for various decorative applications. It is often used in interior design, architecture, and even art installations. Stainless steel sheets can be customized to create unique patterns, textures, and finishes, making them suitable for creating eye-catching and visually appealing decorative elements. Additionally, stainless steel is highly durable, corrosion-resistant, and easy to maintain, making it a practical choice for both indoor and outdoor decorative applications.

- Q: Can stainless steel sheets be used for HVAC systems?

- Yes, stainless steel sheets can be used for HVAC systems. Stainless steel is highly resistant to corrosion and can withstand high temperatures, making it an ideal material for HVAC components such as ductwork, heat exchangers, and exhaust systems. It is also durable and easy to clean, ensuring long-lasting performance in HVAC applications.

- Q: Are stainless steel sheets suitable for escalator claddings?

- Yes, stainless steel sheets are suitable for escalator claddings. Stainless steel is a durable and corrosion-resistant material, making it an excellent choice for high-traffic areas like escalators. It is also easy to clean and maintain, which is important in public spaces. Additionally, stainless steel has a sleek and modern appearance that can enhance the overall aesthetic of the escalator.

- Q: Are stainless steel sheets suitable for fire-rated applications?

- Yes, stainless steel sheets are suitable for fire-rated applications. Stainless steel is known for its high resistance to heat and fire, making it a reliable choice for fire-rated applications. It has a high melting point and does not easily deform or lose its structural integrity when exposed to high temperatures. Additionally, stainless steel does not combust or release toxic fumes when heated, which is crucial in fire-rated applications where safety is a top priority. Stainless steel sheets are commonly used in fire-resistant doors, walls, and other structural components to enhance fire resistance and protect against the spread of flames.

- Q: Are stainless steel sheets available in different patterns?

- Yes, stainless steel sheets are available in different patterns.

- Q: What is the formability of stainless steel sheets?

- The formability of stainless steel sheets is generally good, as they can be easily shaped, bent, and formed into various complex shapes without cracking or breaking.

- Q: Can stainless steel sheets be used for sound insulation?

- Yes, stainless steel sheets can be used for sound insulation to some extent. While stainless steel is not as effective as other materials specifically designed for soundproofing, it still has some soundproofing properties. Stainless steel sheets have a high density which helps in reducing sound transmission. Additionally, they have good reflective properties, meaning they can reflect sound waves and prevent them from passing through. However, it is important to note that for effective sound insulation, it is recommended to use materials specifically designed for this purpose, such as acoustic panels or soundproof curtains, as they offer better sound absorption capabilities.

- Q: Can stainless steel sheets be welded?

- Yes, stainless steel sheets can be welded.

- Q: What are the different types of perforated finishes available for stainless steel sheets?

- Some of the different types of perforated finishes available for stainless steel sheets include round, square, slotted, and decorative patterns. These finishes can be customized to meet specific design requirements and are commonly used in architectural, industrial, and decorative applications.

- Q: How can stainless steel sheets be cleaned and maintained?

- Stainless steel sheets boast exceptional durability and corrosion resistance, making them a favored option for various purposes. To uphold their appearance and functionality, it is crucial to engage in regular cleaning and proper maintenance. Outlined below are the necessary steps for cleaning and maintaining stainless steel sheets: 1. Begin by eliminating loose dirt or debris from the surface using a gentle cloth or brush. This precautionary measure prevents any potential scratching during the cleaning process. 2. Prepare a cleaning solution by combining warm water with a mild detergent or dish soap. Steer clear of abrasive cleaners or products containing chlorine, bleach, or ammonia, as they can harm the stainless steel surface. 3. Immerse a soft cloth or sponge into the cleaning solution and delicately scrub the stainless steel sheet in the direction of the grain. Refrain from applying excessive pressure to avoid scratching. 4. Thoroughly rinse the sheet with clean water to eliminate any residue from the cleaning solution. Ensure that all soap or detergent is completely washed away. 5. Employ a soft, lint-free cloth to dry the stainless steel sheet. It is important to dry it meticulously to prevent the formation of water spots or streaks. 6. For particularly stubborn stains or fingerprints, employ a stainless steel cleaner or specialized stainless steel wipes. Adhere to the instructions provided by the manufacturer for optimal results. These cleaners aid in restoring the luster and removing tough stains or marks. 7. To prevent scratches, avoid using abrasive materials like steel wool or rough brushes when cleaning stainless steel sheets. Instead, opt for soft cloths or non-abrasive sponges. 8. Routinely inspect the stainless steel sheets for any indications of corrosion or damage. If rust spots or pitting are detected, employ a stainless steel cleaner or passivation solution to restore the surface. Seek professional guidance if the damage is extensive. 9. To sustain the appearance of the stainless steel sheet, it is advisable to regularly wipe the surface with a soft cloth or microfiber towel to eliminate dust, fingerprints, or other blemishes. By adhering to these cleaning and maintenance measures, stainless steel sheets can retain their original shine, resist corrosion, and remain in excellent condition for an extended period of time.

Send your message to us

Steel Products From China Stainless Steel 304

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords