Extensible Steel Plastic Geogrids for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

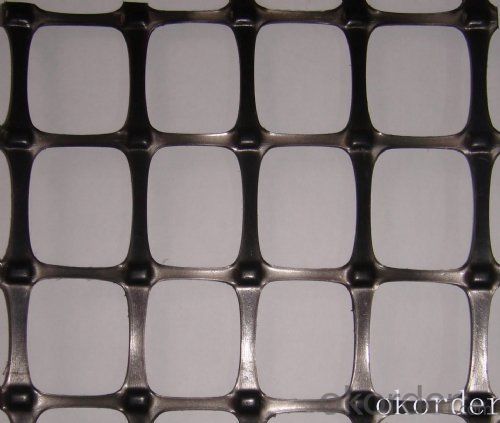

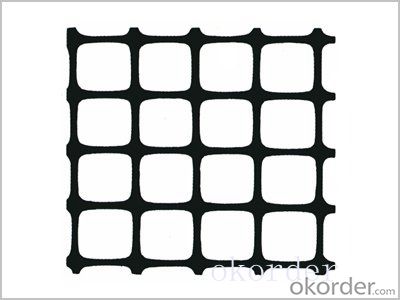

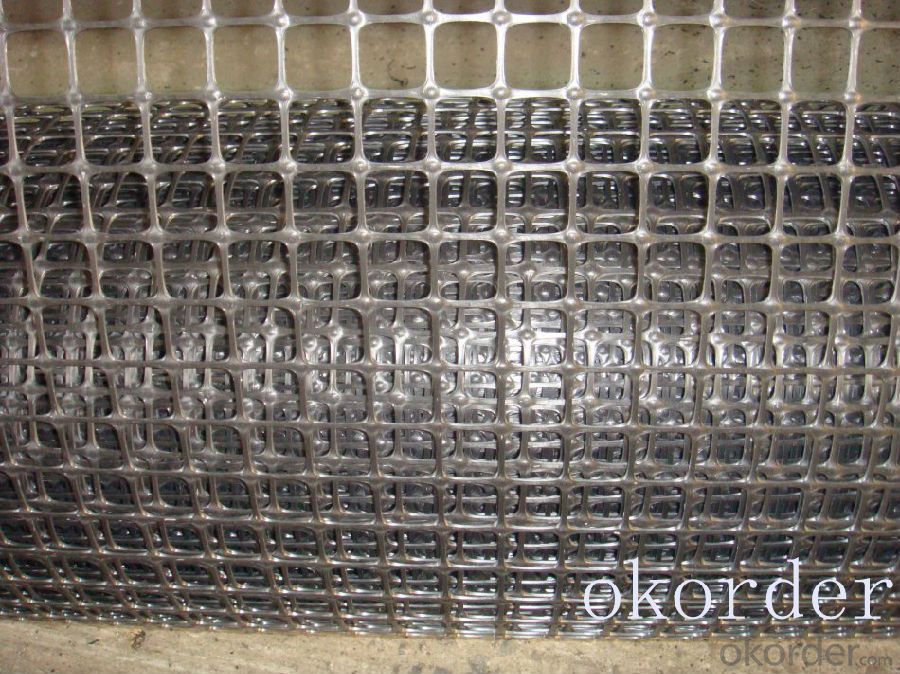

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

Material:

Fiberglass

Tensile strength:

100kn

Roll Width:

3.95m

Roll length:

100 Meter

Porducts Description

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

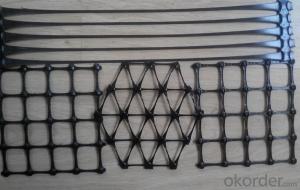

A: Yes, please check the pictures:

- Q: How do geogrids improve the performance of geotextile-reinforced embankments?

- Geogrids improve the performance of geotextile-reinforced embankments by providing additional tensile strength and stability. They help distribute the load more evenly, reducing settlement and enhancing the overall stability of the embankment. Additionally, geogrids prevent lateral spreading and increase the bearing capacity of the soil, making the embankment more resistant to deformation and erosion.

- Q: Are geogrids resistant to seismic forces?

- Yes, geogrids are designed to be resistant to seismic forces. They are made from durable materials that can withstand the dynamic forces generated during an earthquake, providing stability and reinforcement to soil and structures. Geogrids help distribute seismic forces and prevent soil liquefaction, making them a reliable solution in areas prone to earthquakes.

- Q: Especially in the curtain wall project

- There are plastic grille and glass fiber grille (fiberglass), as well as Geotextile

- Q: What are the countries of China's anti dumping

- To play the role of the application of the grid so laying hands straight smooth and uniform paving geogrid every 1.5-2.0m with hook pins fixed on the surface of 3): fill puwan grill and (48) fill every layer filling should be first on both sides, called the principle is strictly prohibited to fill embankment packing allows direct unloading of soil must have finished unloading grille paving soil surface soil unloading height to cut 1m vehicles, construction machinery directly laid geogrid embankment along the axis to allow walking driving 4) geogrid, side and from the grid layer within 8 cm to 6 cm diameter filler

- Q: Product specifications and performance parameters of glass fiber grating

- Glass fiber geogrid technical parameters classification model breaking strength (KN/m) elongation at break (%) mesh size (mm * mm) width (m) meridional zonal glass fiber geogrid

- Q: Are geogrids resistant to hydrolysis?

- Yes, geogrids are generally resistant to hydrolysis.

- Q: What is the calculation method of geogrid?

- Steel plastic grille, plastic grille thickness of about 2-3, the thickness of the glass fiber grille thinner; grams of technical indicators are also reflected inVolume: Volume II: RR*H cylinder algorithm can also estimate a cuboid length * width * height weight algorithm: unit weight * total areaExample: two way plastic grille 30-30KN width of 4 meters, a length of 50 meters, the volume of the volume of 4, the diameter of 35-41cm, some volumes are not round

- Q: Construction technology of steel plastic grille

- (4) the first layer of geogrid paved, began to fill with second layers of 0.2m in thick sand (coarse), the method of sand transport to the site: car unloading to the subgrade side, then put forward to push the bulldozer, within 2 meters on both sides of the subgrade filling after 0.1M, the first layer of geogrid fold up and then fill in 0.1 meters in the sand (coarse), from both sides to the middle filling and advance, prohibit all machinery without filling (coarse sand) of Geogrid on traffic operation, it can guarantee the geogrid is smooth, does not play drums, do not wrinkle, stay in the second layer (coarse) after the formation of sand, the level of measurement, to prevent uneven filling thickness, leveling and correct use of vibratory roller 25T static pressure two times.(5) as the second layer of geogrid layer construction method with the first method, and finally filling in 0.3m (coarse sand), filling in the same way as the first layer, using 25T hydrostatic roller two times, so subgrade reinforcement is dealt with.

- Q: How do geogrids enhance the stability of steep railway cuttings?

- Geogrids enhance the stability of steep railway cuttings by providing reinforcement and increased tensile strength to the soil. These materials are placed within the soil to create a network of interconnected elements, which distribute and transfer loads more efficiently. This helps to resist the lateral forces exerted by the soil, preventing slope failure and maintaining the integrity of the railway cutting.

- Q: How do geogrids improve the performance of geotextile tubes?

- Geogrids improve the performance of geotextile tubes by providing additional structural support and stability. They enhance the tensile strength of the geotextile tubes, preventing deformation and maintaining their shape under pressure. Geogrids also increase the overall load-bearing capacity of the geotextile tubes, making them more effective in erosion control, shoreline protection, and soil stabilization applications.

Send your message to us

Extensible Steel Plastic Geogrids for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords