Geogrids Australia - Steel Plastic Geogrids for Civil Engineering with Low Elongation Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

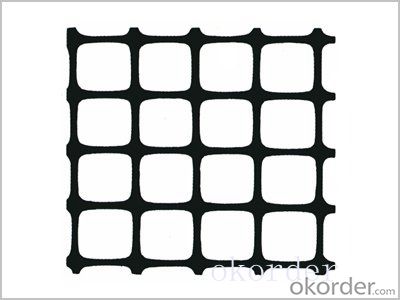

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

nomical solution for filling water stream base and creates almost an ideal surface for laying down a water resistant layer.

steel-plastic composite geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

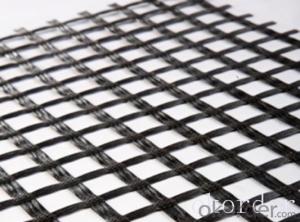

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geogrids environmentally friendly?

- Geogrids can be considered environmentally friendly as they are typically made from recycled materials and help reduce the need for natural resources. Additionally, they can improve soil stabilization and prevent erosion, thereby contributing to the overall sustainability of construction and infrastructure projects. However, it is important to note that the overall environmental impact of geogrids may vary depending on factors such as manufacturing processes and disposal methods.

- Q: Construction method of glass fiber grid

- 3, can not be nailed on the glass fiber grille, can not be directly hit the glass fiber grating with a hammer, after fixing, if the nail is broken or loose iron, you need to be fixed.4, after the completion of the glass fiber grille is fixed, must use roller roller roller stability. So that the grid and the surface of the road is firmly adhered to strictly control the delivery of vehicles mixed in the grid layer on the car to prohibit the emergency steering, emergency braking and pouring of mixed material, in order to prevent damage to the construction of fiberglass grille. 1, preparation work:Complete all of the filling, filling pit, foundation reinforcement and leveling layer laying.

- Q: What are the durability characteristics of geogrids?

- Geogrids are known for their high durability characteristics. They are typically designed to withstand heavy loads, harsh environmental conditions, and long-term exposure to various elements. Geogrids are made from strong materials such as polyester or polypropylene, which provide excellent tensile strength and resistance against stretching or deformation. Additionally, they have good chemical resistance, making them suitable for use in different soil types and corrosive environments. Overall, geogrids offer long-lasting performance and can provide reliable reinforcement and stabilization for various civil engineering applications.

- Q: Are geogrids suitable for use in mechanically stabilized earth walls?

- Yes, geogrids are suitable for use in mechanically stabilized earth walls. Geogrids provide reinforcement to the soil, enhancing its strength and stability. They are commonly used in the construction of mechanically stabilized earth walls to prevent soil erosion, improve load-bearing capacity, and increase overall performance and longevity of the structure.

- Q: Can geogrids be used in ground stabilization for pipelines?

- Yes, geogrids can be used in ground stabilization for pipelines. Geogrids are commonly used in civil engineering applications to reinforce soil and provide stability to structures. In the case of pipelines, geogrids can be used to prevent soil erosion, improve load distribution, and increase the overall stability of the ground, thereby enhancing the long-term performance and safety of the pipeline.

- Q: What are the environmental benefits of using geogrids?

- Geogrids offer several environmental benefits, including soil stabilization, erosion control, and reducing the need for excavation and materials. These geosynthetic materials help prevent soil erosion by reinforcing the ground, preventing sediment runoff into water bodies and protecting natural habitats. Additionally, geogrids can reduce the amount of excavation required for construction projects, minimizing disruption to ecosystems and reducing the consumption of natural resources.

- Q: Can geogrids be installed on steep slopes?

- Yes, geogrids can be installed on steep slopes. Geogrids are commonly used in the construction industry to reinforce soil and provide stability on slopes. They are designed to withstand high tensile forces and can effectively reinforce the soil, preventing erosion and slope failure even on steep slopes.

- Q: Can geogrids be used in soil reinforcement for pipeline projects?

- Yes, geogrids can be used in soil reinforcement for pipeline projects. Geogrids are commonly used in civil engineering applications, including pipeline projects, to enhance the stability and load-bearing capacity of soil. By providing tensile strength to the soil, geogrids can help prevent soil movement, improve soil confinement, and increase the overall performance and longevity of the pipeline.

- Q: What are the typical applications of geogrids?

- Geogrids are commonly used in a variety of applications, including soil stabilization, reinforcement of retaining walls, slope reinforcement, and erosion control. They are also utilized in road construction, landfills, and mining operations. Geogrids help to improve the strength and stability of soil and other materials, making them an essential component in various civil engineering projects.

- Q: Can geogrids be used in temporary construction projects?

- Yes, geogrids can be used in temporary construction projects. Geogrids are often used as reinforcement materials in soil stabilization and retaining walls, providing strength and stability to the construction site. They can be easily installed and removed, making them suitable for temporary applications.

Send your message to us

Geogrids Australia - Steel Plastic Geogrids for Civil Engineering with Low Elongation Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords