Steel Formwork for Living Room with reliable quality and long using time

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

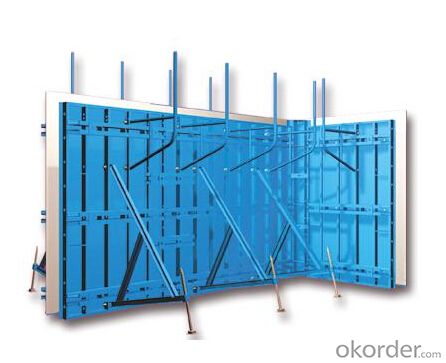

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q: How is steel formwork transported to the construction site?

- Depending on the distance, quantity, and accessibility of the construction site, steel formwork is transported using different methods. Truck transportation is a common choice for shorter distances and smaller quantities. This involves loading the steel formwork components onto a flatbed or trailer and driving them to the site. For larger quantities or longer distances, rail or sea transportation may be used. Rail transport is efficient for moving large quantities over long distances, especially when the site is far from the manufacturing facility. On the other hand, sea transport is ideal for international projects that require shipping the formwork overseas. The formwork is loaded into shipping containers and transported by cargo ships. Upon arrival at the construction site, cranes or forklifts are used to unload the steel formwork. The components are then stored in a designated area until they are ready for installation. It is crucial to carefully plan and execute the transportation process to prevent any damage to the formwork. Any issues with structural integrity can adversely affect the quality and safety of the final construction project.

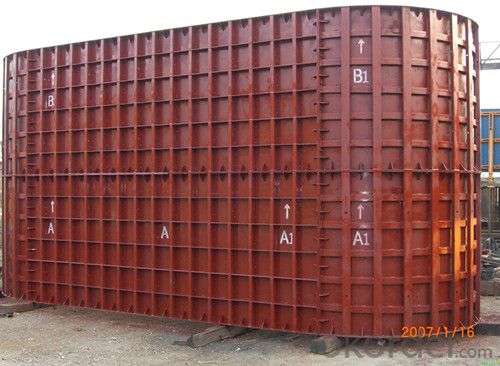

- Q: Can steel formwork be used for precast concrete tanks?

- Yes, steel formwork can be used for precast concrete tanks. Steel is a popular choice for formwork due to its strength, durability, and versatility. It provides the necessary support and shape for the concrete to be poured and cured, ensuring that the tank has the desired dimensions and structural integrity. Steel formwork can be designed and fabricated to meet the specific requirements of precast concrete tanks, allowing for precise and efficient construction. Additionally, steel formwork can be reused multiple times, making it a cost-effective solution for precast concrete tank production.

- Q: What are the safety considerations when using steel formwork?

- When using steel formwork, there are several safety considerations that need to be taken into account. Firstly, it is important to ensure that the formwork is properly installed and secured to prevent any collapses or accidents. Regular inspections should be conducted to check for any signs of wear or damage that could compromise its stability. Another safety consideration is the proper handling and storage of steel formwork. It can be heavy and cumbersome, so workers should be trained in proper lifting techniques to avoid strains or injuries. Adequate storage facilities should be provided to prevent any damage or tripping hazards. Additionally, when working with steel formwork, workers should wear appropriate personal protective equipment (PPE) such as helmets, gloves, and safety boots to protect themselves from any potential hazards or falling debris. They should also be trained in safe work practices, including proper use of tools and equipment, as well as the correct procedures for dismantling the formwork after use. Overall, by following these safety considerations, the risks associated with using steel formwork can be minimized, ensuring a safe working environment for all involved.

- Q: How does steel formwork handle concrete bleeding?

- Steel formwork handles concrete bleeding by providing a strong and rigid structure that prevents excessive flow of water and cement particles from the concrete mixture. The smooth surface of steel formwork also helps in reducing the bleeding by allowing the trapped air and excess water to escape easily. Overall, steel formwork ensures better control over concrete bleeding and helps in achieving a more uniform and compacted concrete structure.

- Q: What are the common design considerations for steel formwork in seismic areas?

- When designing steel formwork for seismic areas, there are several common considerations that need to be taken into account to ensure the safety and stability of the structure. These considerations include: 1. Material strength: The steel used for formwork should have high tensile strength and ductility to withstand the seismic forces. High-strength steel, such as Grade 60 or Grade 80, is often used to ensure the formwork can resist the lateral forces generated during an earthquake. 2. Connection details: The connections between different steel formwork components need to be carefully designed to withstand seismic loads. Proper welding or bolting techniques should be employed to ensure the connections are strong enough to resist the dynamic forces. 3. Reinforcement: Additional reinforcement, such as steel bars or mesh, may be required in the formwork design to enhance its structural integrity. This reinforcement helps to distribute the seismic forces and prevent the formation of weak points or failure zones. 4. Stiffness and rigidity: The formwork system should be designed to be sufficiently stiff and rigid to minimize deformations and prevent excessive movement during an earthquake. This can be achieved by using thicker steel plates or adding diagonal bracing elements to increase the overall stiffness of the system. 5. Anchorage and support: The formwork needs to be securely anchored to the ground or the supporting structure to prevent it from shifting or collapsing during seismic events. Adequate anchorage and support systems, such as anchor bolts or braces, should be incorporated into the design to ensure the stability of the formwork. 6. Compatibility with other building components: The design of the steel formwork should consider its compatibility with other structural elements, such as concrete walls or columns. Proper coordination and integration with other building components are essential to ensure the overall stability and seismic performance of the structure. 7. Robustness and redundancy: The formwork design should have redundancy and robustness features to withstand unexpected loading conditions or localized damage during an earthquake. This can be achieved by incorporating multiple load paths or redundant structural elements into the formwork system. Overall, the common design considerations for steel formwork in seismic areas revolve around ensuring the strength, stability, and compatibility of the formwork system to withstand the dynamic forces generated by earthquakes. By addressing these considerations, engineers can develop robust and resilient formwork designs that contribute to the overall seismic safety of the structure.

- Q: What are the different safety precautions to be followed during steel formwork installation?

- During steel formwork installation, there are several safety precautions that must be followed to ensure the well-being of workers and the overall success of the project. These precautions include: 1. Proper training and supervision: All workers involved in the installation process should be properly trained in handling steel formwork and its components. They should also receive adequate supervision to ensure they are following safety guidelines. 2. Personal protective equipment (PPE): Workers should be provided with and required to wear the appropriate PPE, including hard hats, safety goggles, gloves, and steel-toed boots. This will protect them from potential hazards such as falling objects or sharp edges. 3. Secure footing: It is essential to ensure a stable and secure footing for workers during formwork installation. This can be achieved by clearing debris, maintaining a clean and organized work area, and providing stable platforms or scaffolding. 4. Fall protection: Fall protection measures should be implemented, especially when working at heights. This may include installing guardrails, safety nets, or personal fall arrest systems. Workers should also be trained on how to properly use these systems and equipment. 5. Proper lifting techniques: The use of heavy steel formwork components requires proper lifting techniques to prevent strains, sprains, or other injuries. Workers should be trained on the correct lifting methods, such as bending at the knees and using their leg muscles rather than their back. 6. Equipment inspection: Regular inspection of all equipment, including cranes, hoists, and lifting devices, should be conducted to ensure they are in proper working order. Any defective equipment should be immediately repaired or replaced. 7. Communication and coordination: Effective communication and coordination among workers are crucial to maintaining a safe working environment. This includes clear instructions, proper signage, and regular safety meetings to address any concerns or potential hazards. 8. Fire safety: Steel formwork installation may involve the use of welding or cutting equipment, which presents a fire hazard. Adequate fire prevention measures, such as fire extinguishers and fire-resistant barriers, should be in place, and workers should be trained on proper fire safety protocols. 9. Emergency response plans: It is important to have well-defined emergency response plans in place, including procedures for evacuations, first aid, and contacting emergency services. All workers should be familiar with these plans and know their roles and responsibilities in case of an emergency. By following these safety precautions, the risks associated with steel formwork installation can be minimized, ensuring the well-being and safety of workers and the successful completion of the project.

- Q: Can steel formwork be used for both vertical and horizontal structures?

- Yes, steel formwork can be used for both vertical and horizontal structures. Steel formwork is a versatile and durable construction material that can be molded and shaped to meet the requirements of various structural elements. It can be used for constructing walls, columns, beams, slabs, and other structural elements in both vertical and horizontal orientations. The strength and rigidity of steel make it suitable for withstanding the pressure exerted by concrete during the casting process, ensuring that the formwork maintains its shape and stability. Additionally, steel formwork is reusable and can be easily dismantled and reassembled, making it a cost-effective and efficient choice for construction projects involving both vertical and horizontal structures.

- Q: Can steel formwork be used in hygienic or sterile environments?

- When using steel formwork in hygienic or sterile environments, it is important to take precautions to maintain cleanliness and sterility. Steel formwork is a strong and durable choice for construction and is commonly used in hospitals, laboratories, and food processing facilities. However, it is important to note that steel is not naturally sterile and can harbor bacteria or contaminants if not properly maintained. To ensure the suitability of steel formwork in hygienic or sterile environments, several measures can be taken. Firstly, the formwork should be thoroughly cleaned and sanitized before use. This involves using approved cleaning agents and following specific protocols to remove dirt, debris, and potential contaminants. Furthermore, a protective coating or finish can be applied to the steel formwork to create a smooth and non-porous surface that is easier to clean and disinfect. This helps prevent the accumulation of bacteria or microorganisms on the formwork. Regular maintenance and inspections are also crucial to maintain the hygienic condition of the steel formwork. Any signs of wear, damage, or corrosion should be promptly addressed and repaired to prevent the formation of cracks or crevices where bacteria can grow. It is important to note that in extremely sensitive sterile environments, materials such as stainless steel or specialized plastics may be preferred over traditional steel formwork. These materials have properties that make them more resistant to corrosion, easier to clean, and compatible with strict hygiene or sterilization protocols. Ultimately, the suitability of steel formwork in hygienic or sterile environments depends on the specific requirements and regulations of the environment. Proper cleaning, maintenance, and adherence to hygiene protocols are essential to ensure that steel formwork can be used effectively without compromising cleanliness or sterility.

- Q: What are the common design considerations for steel formwork in earthquake-prone areas?

- Ensuring the safety and stability of structures in earthquake-prone areas requires careful design considerations for steel formwork. Some key factors to consider for steel formwork in these areas include: 1. Material Strength: It is essential to use steel with high tensile strength to withstand the lateral forces generated during earthquakes. Commonly used high-strength steel grades like Grade 60 or Grade 80 are suitable for earthquake-resistant formwork designs. 2. Reinforcement: Adequate reinforcement of the formwork enhances its rigidity and resistance to seismic forces. Adding steel braces, cross-bracing, or diagonal members can provide additional reinforcement to improve the structural integrity of the formwork system. 3. Connection Details: The connections between different formwork elements should be designed to withstand the dynamic forces induced by earthquakes. Welded or bolted connections are commonly utilized, ensuring they have sufficient strength and ductility to resist seismic loads. 4. Stiffness and Flexibility: The formwork system should strike a balance between stiffness and flexibility. It needs to be rigid enough to withstand lateral forces during earthquakes, while also being flexible enough to absorb and dissipate seismic energy without collapsing. 5. Anchorage Systems: Proper anchorage systems are crucial for securing the formwork to the foundation or supporting structure. These systems should be designed to resist uplift and lateral forces during earthquakes, preventing the formwork from overturning or sliding. 6. Diaphragm Action: To enhance overall structural performance, the formwork system should provide diaphragm action. This means that the formwork acts as a continuous and rigid panel, transferring forces across its surface. This reduces localized stresses and improves the overall stability of the structure during earthquakes. 7. Formwork Compatibility: It is essential to ensure that the steel formwork is compatible with other structural elements, such as concrete columns, beams, and slabs. The formwork system must be able to effectively transfer loads from the concrete to the supporting structure without compromising stability or integrity during seismic events. 8. Construction Practices: In addition to design considerations, proper construction practices are vital for the effectiveness of steel formwork in earthquake-prone areas. Adequate bracing and temporary supports should be used during formwork assembly to maintain stability and prevent collapse before the concrete is poured and hardened. By carefully considering these design factors, engineers and designers can develop robust steel formwork systems that can withstand earthquake forces and ensure the safety of structures in seismic regions.

- Q: How does steel formwork affect the overall construction material waste reduction?

- Steel formwork, a construction technique that employs steel panels and frames to create temporary molds or structures for pouring concrete, offers numerous advantages over traditional timber formwork. One notable advantage is its positive effect on reducing overall construction material waste. First and foremost, steel formwork boasts exceptional durability and can be reused multiple times, unlike timber formwork that often requires replacement due to wear and tear after only a few uses. Consequently, steel formwork greatly diminishes the amount of material waste generated during construction, as there is minimal need for regular replacements. Furthermore, steel formwork exhibits greater precision and accuracy compared to timber formwork, resulting in less concrete waste. The precise measurements and tight joints of steel formwork ensure the correct pouring and setting of concrete, minimizing the need for additional material to fill gaps or rectify errors. This reduction in material waste is achieved by minimizing the amount of concrete wasted during the construction process. In addition, steel formwork is highly adaptable and adjustable to various shapes and sizes, allowing for efficient and flexible use in diverse construction projects. Its versatility permits reuse for different structures or modification to meet changing requirements. This adaptability further reduces material waste, as the same formwork can be utilized for multiple projects or repurposed as needed. Moreover, steel formwork is renowned for its high strength and load-bearing capacity, enabling it to withstand substantial concrete pressure without deformation or damage. This strength allows for the construction of taller and more complex structures using steel formwork, reducing the need for additional materials such as support beams or columns. By eliminating the requirement for these extra materials, steel formwork contributes significantly to the overall reduction of construction material waste. In conclusion, steel formwork positively impacts the reduction of construction material waste through its durability, precision, adaptability, and strength. By minimizing the need for regular replacements, reducing concrete waste, allowing for reuse and adaptability, and eliminating the necessity for additional materials, steel formwork plays a vital role in promoting sustainable construction practices and reducing environmental impact.

Send your message to us

Steel Formwork for Living Room with reliable quality and long using time

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches