Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

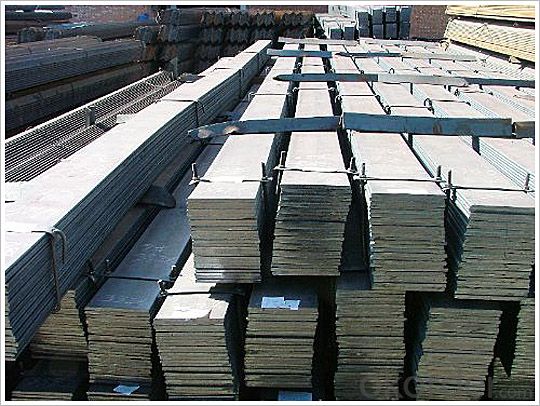

Product Description of Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized:

OKorder is offering mild stainless steel flat bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications of Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized:

Mild stainless steel flat bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages of Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized:

OKorder's Steel flat bar are durable, strong, and resist corrosion.

Main Product Features of Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications of Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized:

Commodity: High Quality Mild Steel Flat Bar

Standard: GB

Material: Q235

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Chemical composition of Q235

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Physical properties of Q235

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

Usage/Applications of Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

Production Flow of High Quality Mild Steel Flat Bar

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

Packaging & Delivery of High Quality Mild Steel Flat Bar

Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

- Q: How do you determine the strength of a steel flat bar?

- There are several methods available for determining the strength of a steel flat bar. One commonly used approach is through tensile testing, which involves applying a pulling force on a specimen until it fractures. This test allows for the measurement of load, deformation, stress, and strain, which can then be used to calculate various mechanical properties such as yield strength, ultimate tensile strength, and elongation. Another method to assess the strength of a steel flat bar is through hardness testing. Hardness is a measure of the material's resistance to indentation or scratching, and it is often indicative of its overall strength. Popular hardness tests for steel include Brinell, Rockwell, and Vickers tests. Furthermore, the strength of a steel flat bar can also be determined by considering its chemical composition. Steel is primarily composed of iron and carbon, but other elements like manganese, chromium, and nickel are added to enhance specific properties. The composition and heat treatment of the steel can greatly influence its strength. It is worth noting that the bending properties of a steel flat bar, such as flexural strength, can also be assessed through tests like the three-point bending test or the four-point bending test. These tests determine the maximum load a specimen can withstand before breaking or yielding under bending forces. In summary, the strength of a steel flat bar can be determined using methods such as tensile testing, hardness testing, considering its chemical composition, and analyzing its bending properties. These approaches provide valuable insights into the steel's mechanical properties, enabling engineers and manufacturers to choose the most suitable steel grade for specific applications.

- Q: Are steel flat bars suitable for the construction of walkways or catwalks?

- Yes, steel flat bars are suitable for the construction of walkways or catwalks. Steel flat bars are known for their strength, durability, and versatility, making them an ideal choice for such applications. They provide a sturdy and reliable surface for walking, capable of withstanding heavy loads and high foot traffic. Additionally, steel flat bars can be easily fabricated, cut, and welded to meet specific design requirements, allowing for customization and flexibility in construction projects. Their resistance to corrosion and weathering also ensures that walkways or catwalks made from steel flat bars will have a longer lifespan and require minimal maintenance. Overall, steel flat bars are a popular and widely used material for constructing walkways or catwalks due to their strength, durability, and adaptability.

- Q: Can steel flat bars be used for making staircases?

- Yes, steel flat bars can be used for making staircases. Steel flat bars are commonly used in construction and fabrication due to their strength and durability. They can be used as the main structural component for staircases, providing support and stability. Additionally, steel flat bars can be easily shaped and welded together to create the desired staircase design. They are also resistant to corrosion, making them suitable for both indoor and outdoor staircases. Overall, steel flat bars are a versatile and reliable choice for constructing staircases.

- Q: What are the different grades of steel used in flat bars?

- The different grades of steel used in flat bars can vary, but some commonly used grades include mild steel, carbon steel, stainless steel, and alloy steel. These grades are chosen based on the specific requirements of the intended application, such as strength, corrosion resistance, and durability.

- Q: What are the different types of surface patterns available for steel flat bars?

- There are several types of surface patterns available for steel flat bars, including plain, serrated, embossed, and diamond.

- Q: What is the difference between a steel flat bar and a steel channel?

- A steel flat bar and a steel channel are both structural steel shapes, but they have distinct differences in their shape and design. A steel flat bar is a long, rectangular-shaped piece of steel with straight edges. It is commonly used in construction and manufacturing industries for various applications such as braces, supports, and frames. The flat surface of the bar provides stability and strength, making it suitable for load-bearing purposes. The width and thickness of a flat bar can vary depending on the specific requirements of a project. On the other hand, a steel channel is a C-shaped structural component with two flanges and a web in the middle. The flanges are perpendicular to the web, giving the channel its distinctive shape. Channels are widely used in construction, particularly in the framing of buildings and the creation of structural support systems. The flanges provide strength and rigidity to the channel, making it suitable for applications where lateral support and stability are required. In summary, the main difference between a steel flat bar and a steel channel lies in their shape and structural design. While a flat bar is a long, rectangular piece with straight edges, a channel has a C-shaped profile with flanges and a web. The choice between the two depends on the specific requirements of a project and the type of load-bearing or support function it needs to fulfill.

- Q: What are the weight and load-bearing capacities of different steel flat bar sizes?

- Steel flat bars can have varying weight and load-bearing capacities depending on their size. Generally, the larger the flat bar, the greater its weight and load-bearing capacity. Below are some common sizes of steel flat bars and their approximate weight and load-bearing capacities: 1. For a thin flat bar that is 1/8 inch thick, it is typically used for lighter applications. Its weight can range from around 0.42 pounds per foot, and its load-bearing capacity is approximately 200 pounds per foot. 2. If the flat bar is slightly thicker at 1/4 inch, it can handle heavier loads. It typically weighs around 0.85 pounds per foot and has a load-bearing capacity of about 400 pounds per foot. 3. A thicker option is the 3/8 inch steel flat bar, which can support even greater loads. Its weight can range from around 1.27 pounds per foot, and its load-bearing capacity is approximately 600 pounds per foot. 4. Significantly thicker, the 1/2 inch steel flat bar is commonly used for heavy-duty applications. It weighs around 1.7 pounds per foot and has a load-bearing capacity of about 800 pounds per foot. 5. For extremely heavy loads, the 1 inch thick steel flat bar is suitable. It typically weighs around 3.4 pounds per foot and has a load-bearing capacity of approximately 1600 pounds per foot. It is important to note that these weight and load-bearing capacities are approximate and can vary based on the grade and quality of the steel used. Other factors such as the length and support conditions of the flat bar should also be considered when determining its maximum load-bearing capacity. It is advisable to consult professional engineers or refer to load tables provided by steel manufacturers for accurate and specific information on the weight and load-bearing capacities of steel flat bars.

- Q: Can steel flat bars be galvanized or coated with zinc?

- Yes, steel flat bars can be galvanized or coated with zinc. This process helps to protect the steel from corrosion and rust, extending its lifespan and enhancing its durability.

- Q: Can steel flat bars be used for manufacturing construction equipment?

- Yes, steel flat bars can be used for manufacturing construction equipment. Steel flat bars are versatile and strong, making them suitable for a wide range of applications, including in the construction industry. They can be used to fabricate various components of construction equipment, such as frames, supports, brackets, and reinforcements. Additionally, steel flat bars can withstand heavy loads, provide structural stability, and are resistant to corrosion, making them an ideal choice for manufacturing construction equipment that needs to withstand harsh working conditions.

- Q: Can steel flat bars be used for making furniture or fixtures?

- Absolutely, steel flat bars are absolutely suitable for furniture or fixture production. With their versatility and strength, steel flat bars are perfect for crafting long-lasting and practical pieces. They can be employed in the construction of a wide range of furniture, including tables, chairs, shelves, and cabinets, as well as fixtures such as brackets, frames, and supports. The stability and structural integrity offered by steel flat bars make them highly favored in both industrial and modern designs. Moreover, steel can be effortlessly welded, bent, or shaped to fulfill specific design demands, allowing for the creation of distinctive and personalized furniture or fixtures.

Send your message to us

Steel Flat Bar EN Hot Rolled High Quality China Steel Galvanized

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords