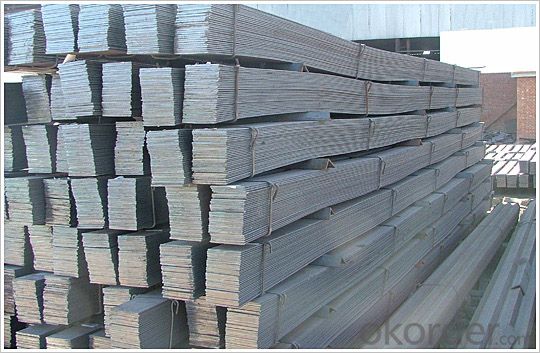

Hot Rolled Steel Flat Bars Perforated Hot Galvanized Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Flat Bars Perforated (Hot Galvanized)Made In China at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Flat Bars Perforated (Hot Galvanized)Made In China are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Flat Bars Perforated (Hot Galvanized)Made In China are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specification of Mild Steel Flat Bar

Commodity: Mild Steel Flat Bar

Standard: GB;JIS

Material: Q195-235;SS400

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Packaging & Delivery of Hot Rolled Steel Flat Bars

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do you prevent steel flat bars from scratching or damaging surfaces?

- To avoid scratching or damaging surfaces with steel flat bars, there are several precautions you can take: 1. Employ protective coverings: Affix adhesive-backed felt or rubber pads to the underside of the steel flat bars. This will create a cushioning layer that prevents direct contact between the steel and the surface, reducing the likelihood of scratches or damage. 2. Establish proper storage: When not in use, store the steel flat bars in a designated area where they won't come into contact with delicate surfaces. Utilizing a rack or container specifically designed for steel bars can help prevent accidental scratching. 3. Handle with caution: Exercise care when moving or transporting the steel flat bars to avoid dragging or sliding them across surfaces. Instead, lift and carry them to minimize the risk of scratching. 4. Clean the surface: Prior to placing the steel flat bars on a surface, ensure that it is clean and free from debris or particles that could potentially cause scratches. Wipe the surface with a soft cloth or use a mild cleaner to remove any dirt or dust. 5. Utilize protective barriers: If you need to place steel flat bars on delicate or highly polished surfaces, consider using protective barriers like a thick blanket or rubber mat. These barriers act as a shield between the steel and the surface, preventing any direct contact and reducing the risk of scratches. By implementing these preventive measures, you can significantly decrease the likelihood of steel flat bars scratching or damaging surfaces, ensuring the durability and quality of both the bars and the surfaces they encounter.

- Q: Can steel flat bars be used for making signage?

- Indeed, signage can be crafted from steel flat bars. Steel, being a resilient and adaptable material, can be effortlessly manipulated, sliced, and fused to produce an array of signage designs and dimensions. Steel flat bars can serve as the primary framework or foundation of the sign, delivering stability and reinforcement. Furthermore, they can serve as embellishments, imparting a polished and contemporary aesthetic to the signage. Moreover, steel boasts resistance against weathering and corrosion, rendering it ideal for both interior and exterior signage. In summary, steel flat bars present a pragmatic and dependable option for signage fabrication.

- Q: Can steel flat bars be galvanized or coated with zinc?

- Yes, steel flat bars can be galvanized or coated with zinc. This process helps to protect the steel from corrosion and rust, extending its lifespan and enhancing its durability.

- Q: Are steel flat bars resistant to fire?

- Yes, steel flat bars are generally resistant to fire. Steel is a non-combustible material, meaning it does not burn or contribute to the spread of fire. Steel's high melting point and excellent heat resistance make it highly resistant to the effects of fire. This makes steel flat bars a popular choice for various applications where fire resistance is required, such as in construction, manufacturing, and industrial settings. However, it is important to note that while steel itself is resistant to fire, other materials attached to or surrounding the steel bars may not be. Therefore, it is crucial to consider the entire system and ensure that all components are fire-resistant to ensure maximum fire protection.

- Q: Can steel flat bars be used for making storage systems?

- Indeed, storage systems can be fashioned using steel flat bars. Due to its durability and strength, steel proves to be an appropriate material for fabricating storage systems capable of enduring substantial weights and offering structural reinforcement. Steel flat bars present an opportunity to construct shelves, racks, and frames to accommodate storage systems found in warehouses, retail establishments, or even residential or office spaces. Moreover, steel flat bars can be effortlessly welded, cut, and molded according to precise design prerequisites, rendering them versatile in crafting tailor-made storage resolutions.

- Q: Lightning protection grounding, what is called three surface welding?

- When lap welding is adopted, the welding length is as follows:1, galvanized steel bar is not less than its width of 2 times, three surface welding. When the width of flat steel is different, the length of lap should be wide. Before laying, the flat steel should be adjusted straight, simmer, bend not to die, straight line should not be obvious bending, and should stand upright.2, galvanized round steel welding length of 6 times its diameter, and should be double-sided welding (when the diameter is not the same, the length of overlap in diameter should prevail).3, galvanized round steel and galvanized flat steel connection, its length is round steel diameter of 6 times.4, galvanized flat steel and galvanized steel pipe welding, in order to connect reliable, in addition to contact in itBoth sides of the site shall be welded, and the flat steel itself shall be bent in an arc to be welded with the steel pipe.

- Q: Are steel flat bars suitable for welding or soldering?

- Yes, steel flat bars are suitable for welding or soldering. Steel is a versatile and commonly used material in various industries, including construction, manufacturing, and automotive. Steel flat bars are often used for structural purposes and can be easily welded or soldered together to create larger structures, such as frames or supports. Both welding and soldering methods can effectively join steel flat bars, depending on the specific application and desired strength of the connection. Welding involves melting and fusing the steel together, creating a strong and permanent bond. Soldering, on the other hand, uses a lower temperature to melt a filler material (solder) that flows into the joint, creating a solid connection. However, it is important to note that the specific type of steel used in the flat bars, such as carbon steel or stainless steel, may require different welding or soldering techniques and materials. It is always recommended to consult with a professional or refer to the manufacturer's guidelines for specific instructions on welding or soldering steel flat bars.

- Q: Can steel flat bars be used for tooling or machinery components?

- Yes, steel flat bars can be used for tooling or machinery components. Steel is a strong and durable material that can withstand high loads and provide stability and support. Flat bars can be easily shaped, machined, and welded to create various tooling or machinery components such as brackets, supports, frames, or base plates. Additionally, steel's resistance to rust and corrosion makes it suitable for use in different environments and conditions.

- Q: What are the different types of surface finishes for copper steel flat bars?

- Copper steel flat bars can be given various surface finishes. The manufacturing process typically applies a standard mill finish, which gives the bars a smooth and shiny appearance with slight imperfections from milling. For a more polished look, the flat bars can be buffed to achieve a high shine and smooth texture. This polished finish is often used for decorative purposes. Another option is a brushed finish, where the surface of the flat bar is textured by brushing it with a wire brush. This can be done in different directions to create various effects. A satin finish, on the other hand, provides a smooth and matte appearance with a subtle sheen. It is achieved by brushing the surface with a fine abrasive material like sandpaper or a nylon pad. For an aged or weathered appearance, an antiqued finish is applied by using chemical treatments or patinas on the surface of the flat bar. This adds character and depth to the metal. These examples illustrate the range of surface finishes available for copper steel flat bars. The choice of finish will depend on factors such as the desired aesthetic, functionality, and specific project requirements.

- Q: Are steel flat bars available in different colors or coatings?

- No, steel flat bars are typically not available in different colors or coatings. They are generally produced in their natural steel color and finish.

Send your message to us

Hot Rolled Steel Flat Bars Perforated Hot Galvanized Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords