High Quality of Cold Rolled Steel Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Cold Rolled Steel Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling continuous rolling, degreasing, annealing,skin pass,slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The product is widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

2.Main Features of the Cold Rolled Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

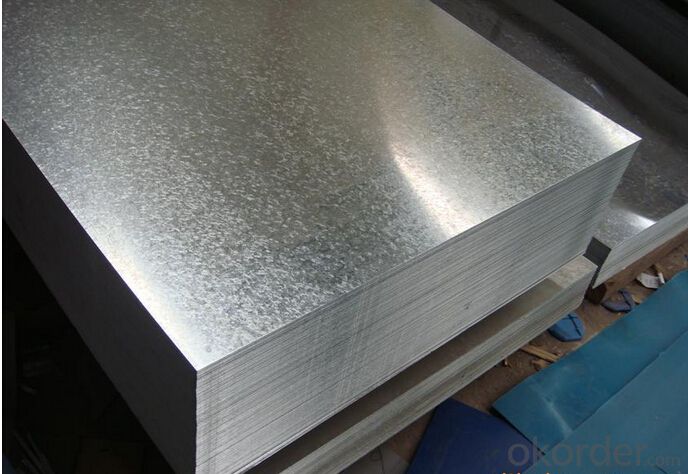

3.Cold Rolled Steel Images

4.Cold Rolled Steel Specification

Standard:AISI,ASTM,DIN,GB,JIS,JIS G3302 ASTM 653M EN10142

Grade: Q195~Q345

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Cold Rolled Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Can steel sheets be used for construction formwork or molds?

- Certainly, construction formwork or molds can utilize steel sheets, although their usage may not be as prevalent as materials like plywood or timber. Robust and enduring, steel sheets offer a sleek and uniform surface for concrete casting. They prove especially fitting for expansive construction ventures demanding formwork capable of withstanding immense pressures and loads. Additionally, steel sheets can be tailor-made and manufactured to meet precise project specifications, affording versatility in terms of shape, size, and arrangement. Nevertheless, the cost, weight, and accessibility of steel sheets should be weighed against alternative formwork materials prior to reaching a verdict.

- Q: What can be painted on galvanized steel sheet?

- Zinc coating in the atmospheric environment after exposure, the surface will form a zinc salt (also known as white rust), before coating the paint, these zinc salts must be completely eliminated. The most effective treatment is the light sweep sand blasting method; if it is impossible to use sandblasting, you can use wire brushes or steel wool and full fresh water to remove zinc salts by mechanical cleaning and washing.

- Q: Are steel sheets suitable for railway or transportation infrastructure?

- Yes, steel sheets are suitable for railway or transportation infrastructure. Steel is a strong and durable material that can withstand heavy loads and extreme weather conditions, making it ideal for constructing railway tracks, bridges, and transportation structures. Additionally, steel sheets can be easily fabricated, allowing for efficient construction and maintenance of transportation infrastructure.

- Q: Are steel sheets suitable for HVAC systems?

- Yes, steel sheets are suitable for HVAC systems. Steel sheets are commonly used in HVAC systems due to their durability, strength, and resistance to corrosion. They provide structural integrity to the system and can withstand high temperatures and pressure. Additionally, steel sheets are easy to fabricate and can be customized to fit specific HVAC system requirements. They are also cost-effective and have a long lifespan, making them a preferred choice for HVAC system components such as ductwork, ventilation systems, and air handling units.

- Q: How are steel sheets classified based on their surface finish?

- Steel sheets can be classified based on their surface finish into several categories, including hot rolled, cold rolled, and coated finishes.

- Q: What are the different types of steel sheet finishes for decorative purposes?

- For decorative purposes, one can find several varieties of steel sheet finishes that are commonly utilized. These finishes are applied to the steel sheet's surface with the intention of enhancing its appearance and achieving a desired aesthetic effect. Some of the most favored finishes for decorative purposes are as follows: 1. Brushed Finish: Achieved by brushing the steel sheet's surface with a fine abrasive material, usually in a straight line pattern, this finish imparts a smooth and satin-like appearance. It is widely used in architectural and interior design applications. 2. Mirror Finish: Also known as a polished finish, this type creates a highly reflective surface that resembles a mirror. The steel sheet is mechanically polished to achieve this finish, and it is commonly seen in decorative applications such as furniture, lighting fixtures, and signage. 3. Patterned Finish: This finish involves embossing or etching a pattern onto the steel sheet's surface. It can be achieved through various techniques like stamping, laser engraving, or chemical etching. Patterned finishes provide a decorative and textured appearance and are often used in applications like elevator panels, wall cladding, and decorative screens. 4. Colored Finish: To add vibrancy and enhance visual appeal, steel sheets can be coated with a colored finish. Processes such as powder coating are employed, where a dry powder is applied to the steel sheet and then cured to create a durable, colored finish. Colored finishes are commonly used in architectural applications like building facades and signage. 5. Antique Finish: This particular finish is designed to give the steel sheet an aged or weathered look, resembling antique metal. Various techniques such as chemical treatments, patinas, or distressing can be employed to achieve this appearance. Antique finishes are often utilized in decorative applications to create a rustic or vintage aesthetic. These are just a few examples of the diverse range of steel sheet finishes available for decorative purposes. Each finish provides a distinct appearance and can be customized to suit specific design preferences. The choice of finish relies on factors such as the desired look, application, and required level of durability for the project.

- Q: What are the different manufacturing processes for steel sheets?

- Steel sheets can be manufactured through various processes, each with its own unique characteristics and applications. Some commonly used methods include: 1. The most widely employed technique is hot rolling, which involves heating the steel billet or slab to a high temperature and passing it through rollers to reduce its thickness. As a result, the sheets have a smooth surface and excellent mechanical properties. 2. Cold rolling, on the other hand, rolls the steel at room temperature, yielding sheets with higher dimensional accuracy and surface finish. This process is often employed to produce sheets with tight tolerances and improved surface quality. 3. Galvanizing is a process where steel sheets are coated with a layer of zinc to prevent corrosion. The sheets are either immersed in molten zinc or electroplated with it, forming a protective barrier that extends the steel's lifespan. 4. Coating processes can also be applied to steel sheets to enhance their properties or appearance. For instance, powder coating involves electrostatically applying a dry powder that is then cured under heat. Paint coating, on the other hand, entails applying a liquid paint to the surface and allowing it to dry. 5. Pickling, a chemical process, is employed to remove impurities like rust, scale, and oxides from the surface of steel sheets. Typically, the sheets are immersed in an acid bath that dissolves these unwanted materials, leaving behind a clean surface. 6. Once the steel sheets are manufactured, they can undergo cutting and forming operations. Laser cutting, plasma cutting, or shearing can be utilized to shape the sheets into desired sizes and shapes. Additionally, the sheets can be formed into various products using techniques like bending, deep drawing, or roll forming. These examples highlight the different manufacturing processes for steel sheets, and the choice of method depends on factors such as desired sheet properties, surface finish, and intended application.

- Q: What are the different joining methods for steel sheets?

- There are several different joining methods for steel sheets, including welding, bolting, riveting, and adhesive bonding. Welding involves melting the edges of the steel sheets and fusing them together, creating a strong and permanent bond. Bolting involves using screws or bolts to connect the steel sheets, providing a secure and adjustable connection. Riveting involves using rivets to connect the steel sheets by deforming the rivet to create a mechanical bond. Adhesive bonding involves using specialized adhesives to bond the steel sheets together, creating a strong and lightweight connection.

- Q: Are steel sheets suitable for data center infrastructure?

- Indeed, data center infrastructure can rely on steel sheets. The utilization of steel sheets in the establishment of data centers is prevalent because of their exceptional robustness, longevity, and resistance to fire. Furthermore, they furnish essential support for the infrastructure, encompassing server racks, cabinets, and raised flooring systems. Not only do steel sheets safeguard data center equipment against potential dangers such as electromagnetic interference (EMI) and physical harm, but they can also be conveniently tailored and adapted to suit the precise demands of a data center. This adaptability renders them a favored option for constructing data center infrastructure.

- Q: What is galvanized steel sheet?

- Galvanized steel sheet is a type of steel that has been coated with a layer of zinc to protect it from rust and corrosion. This coating is applied through a process called galvanization, which helps to significantly extend the lifespan of the steel and make it more durable.

Send your message to us

High Quality of Cold Rolled Steel Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords