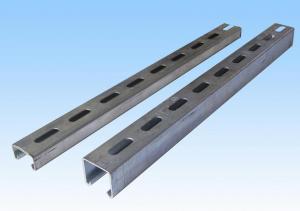

GB Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of MS Channel:

1.We supply high quality MS Channel at reasonable price, including Chinese standard, Japanese standard and so on.

Standard | GB/JIS |

Material Grade | Q235,SS400 |

Technique: | Hot Rolled |

Sizes as per chinese standard: | 50*37*4.5mm - 300*89*11.5mm

|

Sizes as per japanese standard: | 50*25*3mm – 200*80*7.5mm |

Length: | 6meter, 9meter, 12meter |

Note: 1.we are also competent to provide our customers other MS Channel based on other sizes according to customer’s requirements.

2. The length of our ms channel could be cut into other meters as per customer’s requirements. For example, the channel in 6meters could be cut into 5.8meters in order to be fit in the 20ft container.

2. The detailed sections of MS Channel as per GB standard.are shown in the table-1:

GB U CHANNEL | Standard | Sectional | Dimension |

| Mass: |

| (mm) | (mm) | (mm) | (mm) |

|

50X37 | 50 | 37 | 4.50 | 7.0 | 5.438 |

63X40 | 63 | 40 | 4.80 | 7.5 | 6.634 |

80x43 | 80 | 43 | 5.00 | 8.0 | 8.045 |

|

|

|

|

|

|

100x48 | 100 | 48 | 5.30 | 8.5 | 10.007 |

120x53 | 120 | 53 | 5.50 | 9.0 | 12.059 |

140x58 | 140 | 58 | 6.00 | 9.5 | 14.535 |

140x60 | 140 | 60 | 8.00 | 9.5 | 16.733 |

|

|

|

|

|

|

160x63 | 160 | 63 | 6.50 | 10.0 | 17.240 |

160x65 | 160 | 65 | 8.50 | 10.0 | 19.752 |

|

|

|

|

|

|

180x68 | 180 | 68 | 7.00 | 10.5 | 20.174 |

180x70 | 180 | 70 | 9.00 | 10.5 | 23.000 |

|

|

|

|

|

|

200x73 | 200 | 73 | 7.00 | 11.0 | 22.637 |

200x75 | 200 | 75 | 9.00 | 11.0 | 25.777 |

|

|

|

|

|

|

220x77 | 220 | 77 | 7.00 | 11.5 | 24.999 |

220x79 | 220 | 79 | 9.00 | 11.5 | 28.453 |

|

|

|

|

|

|

250x78 | 250 | 78 | 7.00 | 12.0 | 27.410 |

250x80 | 250 | 80 | 9.00 | 12.0 | 31.335 |

250x82 | 250 | 82 | 11.00 | 12.0 | 35.260 |

|

|

|

|

| |

280x82 | 280 | 82 | 7.50 | 12.5 | 31.427 |

280x84 | 280 | 84 | 9.50 | 12.5 | 35.823 |

280x86 | 280 | 86 | 11.50 | 12.5 | 40.219 |

|

|

|

|

|

|

300x85 | 300 | 85 | 7.50 | 13.5 | 34.463 |

300x87 | 300 | 87 | 9.50 | 13.5 | 39.173 |

300x89 | 300 | 89 | 11.50 | 13.5 | 43.883 |

Table-1

3. The chemical composition of HR Channel Steel according to Q235B is shown in Table-2.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12-0.20 | 0.3-0.7 | ≦0.045 | ≦0.045 | ≦0.3 |

Table-2

Note: we are able to present our customers relevant SGS test report for chemical composition of HR Channel Steel.

4. The mechanical property of HR Channel Steel according to Q235B is shown in Table-3-1 and Table-3-2

Alloy No | Grade | Yielding Strength Point(Mpa) | |||

Thickness(mm) | |||||

≦16 | >16-40 | >40-60 | >60-100 | ||

≧ | |||||

Q235 | B | 235 | 225 | 215 | 205 |

Table-3-1

Alloy No | Grade | Tensile Strength(Mpa) | Elongation After Fracture(%) | |||

Thickness(mm) | ||||||

≦16 | >16-40 | >40-60 | >60-100 | |||

≧ | ||||||

G235 | B | 375-500 | 26 | 25 | 24 | 23 |

Table-3-2

Note: we are able to present our customers relevant SGS test report for mechanical property of MS Channel as customer’s request.

Applications of MS Channel:

The MS Channel can be applied to construction of warehouses, workshops, sport stadiums and car parks etc.The hot rolled channel steel belongs to carbon structural steel which is applied to in the field of construction and machinery.In details, the hot rolled channel steel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. Generally,the hot rolled channel steel we supply must possess perfect welding property, riveting property and mechanical property and so on.

Package & Delivery of MS Channel:

1.The hot rolled channel steel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

2. And the hot rolled channel steel could be loaded into 20ft or 40ft container, or by bulk cargo.If the weight of each bundle reaches more than 3.5 mt, the loading by break bulk cargo should be choosed.When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

3.As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4.All in all, we could do in accordance with customer's request.

- Q: What are the different spans achievable with steel channels?

- The different spans achievable with steel channels vary depending on several factors such as the size and shape of the channel, the type of steel used, and the load requirements. However, steel channels can typically be used for spans ranging from a few feet to several hundred feet, making them a versatile choice for structural applications.

- Q: How do steel channels contribute to the overall sustainability certifications of a project?

- Steel channels contribute to the overall sustainability certifications of a project in several ways. Firstly, steel channels are highly durable and have a long lifespan, which reduces the need for frequent replacements and repairs. This not only saves resources but also minimizes waste generation throughout the project's lifecycle. Additionally, steel channels are often made from recycled materials, which further decreases the demand for virgin resources and reduces the carbon footprint associated with their production. The use of recycled steel channels also helps divert waste from landfills, contributing to waste reduction goals and promoting a circular economy. Furthermore, steel channels are highly recyclable at the end of their life, allowing for their reuse in other projects. This reduces the demand for new steel production and conserves energy and resources that would have been required for manufacturing new channels. Moreover, steel's strength and load-bearing capacity make it an excellent material for structural applications, enabling the construction of more efficient and sustainable buildings. Steel channels can support larger spans and higher loads, which allows for the use of lighter and more sustainable building materials in other areas of the project. Lastly, steel channels can contribute to a project's sustainability certifications by enabling the design and construction of energy-efficient structures. They can be incorporated into innovative building systems, such as passive solar design or efficient HVAC systems, which can reduce energy consumption and greenhouse gas emissions associated with the project. In summary, steel channels contribute to the overall sustainability certifications of a project by providing durability, utilizing recycled materials, promoting recycling at the end of life, enabling efficient designs, and supporting energy-efficient construction practices.

- Q: What are the different methods of protecting steel channels from corrosion?

- There are several methods of protecting steel channels from corrosion, including galvanization, painting, powder coating, and applying corrosion-resistant coatings.

- Q: How do steel channels contribute to the overall sustainability of a structure?

- Steel channels contribute to the overall sustainability of a structure in several ways. First and foremost, steel is a highly durable and long-lasting material. It is resistant to corrosion, weathering, and degradation, which means that structures built with steel channels have a longer lifespan compared to structures made with other materials. This durability reduces the need for frequent repairs or replacements, ultimately reducing the environmental impact associated with construction and demolition waste. Additionally, steel channels are lightweight yet strong, allowing for efficient use of materials. This means that less steel is required to achieve the same structural strength, leading to reduced resource consumption and energy usage during the manufacturing process. Moreover, steel is a recyclable material, and steel channels can be easily repurposed or recycled at the end of their life cycle. Recycling steel reduces the demand for new raw materials and saves energy that would be required in the production of new steel. Furthermore, steel channels offer design flexibility and versatility, enabling architects and engineers to create innovative and sustainable structures. Steel channels can be easily shaped, welded, and assembled, facilitating the construction process and allowing for a wide range of architectural designs. This flexibility also allows for future modifications or expansions without requiring extensive demolition or reconstruction. Lastly, steel channels have excellent fire resistance properties. Steel is non-combustible and does not contribute to the spread or intensity of fires, which enhances the safety of the structure and reduces the risk to occupants and neighboring buildings. In summary, steel channels contribute to the overall sustainability of a structure through their durability, efficient use of materials, recyclability, design flexibility, and fire resistance. By choosing steel channels, we can create structures that are not only environmentally friendly but also safe, long-lasting, and cost-effective in the long run.

- Q: What are the different material specifications for steel channels?

- There are various material specifications for steel channels, such as the American Standard Channels (C-shape), which are designated by their height and weight per foot. Another specification is the European Standard Channels (U-shape), which are identified by their dimensions and weight per meter. Additionally, steel channels can be produced in different grades, such as A36, A572, and A588, which determine their mechanical properties and suitability for specific applications.

- Q: What are the different cross-sectional shapes available for steel channels?

- The different cross-sectional shapes available for steel channels include C-shape, U-shape, and Z-shape.

- Q: How do steel channels contribute to the overall efficiency of a building?

- Steel channels contribute to the overall efficiency of a building in several ways. Firstly, they provide structural support, enhancing the strength and stability of the building. This allows for the construction of taller and larger structures, maximizing the use of space. Additionally, steel channels can be used to create open floor plans, allowing for flexible and versatile layouts. Moreover, steel channels are lightweight yet durable, making them easy to transport and install, reducing construction time and costs. Lastly, steel channels have high resistance to fire, corrosion, and pests, ensuring the long-term durability and safety of the building.

- Q: Channel 40 is used as a support leg. How many tons can each bear?

- Bearing capacity determined by strengthThe maximum thickness of the member cross section is 18.00mm, according to GB50017-2003, 3.4.1-1, f = 205.00N/mm2According to GB/T 700-1988 and GB/T 1591-1994, FY =225.00N/mm2According to formula 5.1.1-1,N1 = 1 x F X An = 1 x 205 x 67.54 x 102103 = 1384.49kN

- Q: Can steel channels be used for stair stringers in commercial buildings?

- Yes, steel channels can be used as stair stringers in commercial buildings. Steel channels are often preferred for their strength, durability, and load-bearing capabilities, making them suitable for supporting staircases in high-traffic areas such as commercial buildings. Additionally, steel channels can be easily fabricated and installed, providing a reliable and long-lasting solution for stair stringers in these settings.

- Q: How are steel channels resistant to corrosion?

- Steel channels are resistant to corrosion due to the protective oxide layer that forms on their surface when exposed to oxygen in the air. This layer acts as a barrier, preventing moisture and other corrosive substances from coming into direct contact with the steel, thereby reducing the likelihood of corrosion.

Send your message to us

GB Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords