Steel Billet in Square Straight Form Big Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Billet in Square Straight Form Big Sizes Description:

Steel billet in square straight form big sizes is a bar with square shaped cross-section. It is special case of equal sides. Before steel products are sold on the market, the steel must first be processed into more functional pieces. Raw steel cannot be of use while in its pure form, thus it has to be cast into shape. The freshly made steel, steel billet in square straight form big sizes is still in the form of a metal bar or rectangle. Small sizes of steel billet in square straight form big sizes are used in ship building.

2. Main Features of Steel Billet in Square Straight Form Big Sizes:

• Grade: Q235

• Type: Mild carbon steel

• A quadrilateral with four equal sides and four right angles.

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

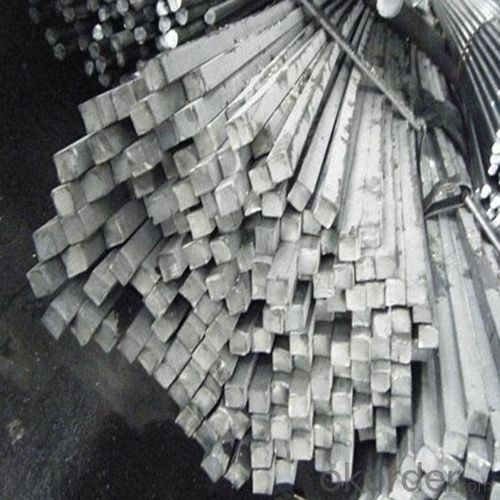

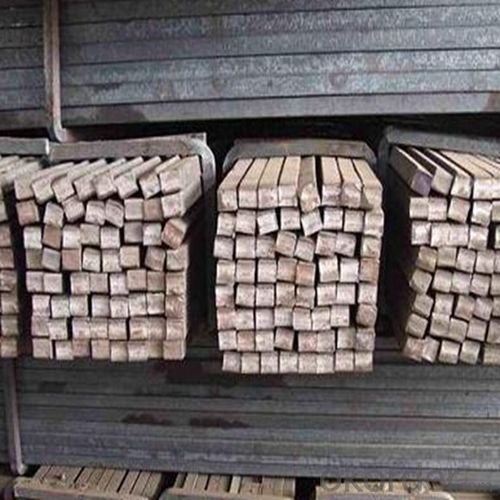

3. Steel Billet in Square Straight Form Big Sizes Images:

4. Steel Billet in Square Straight Form Big Sizes Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①What is the main material?

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: What are the different parts of a steel square?

- A steel square, also referred to as a framing square or carpenter's square, is composed of multiple essential components that contribute to its functionality. The primary elements of a steel square are as follows: 1. Blade: On one side of the square, there is a lengthy, flat metal surface known as the blade. It is typically inscribed with measurements and angles, enabling precise measurements and layout work. 2. Tongue: Located at the end of the blade, the tongue is a shorter segment of metal. Positioned perpendicular to the blade, it is commonly utilized to mark and measure short distances. 3. Heel: Positioned opposite to the tongue, the heel represents the wider end of the steel square. It serves as a stable platform and acts as a reference point for creating square cuts and angles. 4. Face: The face, which is perpendicular to both the blade and tongue, denotes the flat part of the square. It is commonly employed for drawing straight lines and verifying the squareness of corners. 5. Fence: Along the face of the square, there is an elevated edge called the fence. It aids in securely holding the square against the workpiece, ensuring accurate measurements and straight lines. 6. Graduations: The blade and face of the square exhibit markings or measurements referred to as graduations. These graduations facilitate precise measurements of distances, angles, and cuts. 7. Squaring and Angle Scales: Typically located on the face of the square, squaring and angle scales are employed to measure angles other than 90 degrees. They prove useful for marking angles, bevels, and intricate cuts. 8. Rafter Tables: Certain steel squares incorporate rafter tables, which are engraved charts or tables found on the blade. These tables provide information and calculations for various roof framing applications, such as determining rafter lengths and angles. In summary, the diverse components of a steel square collaboratively contribute to accuracy, stability, and versatility for various carpentry and layout tasks.

- Q: What are some common uses for a steel square in metalworking?

- The steel square, also known as a combination square, is a tool widely used in metalworking for various purposes. Below are some of its common applications: 1. Measurement and marking: The primary use of steel squares is to measure and mark accurate angles and dimensions on metal surfaces. With its built-in 90-degree angle, it allows for precise right-angle measurements, ensuring precise cuts and welds. 2. Layout tasks: Metalworkers heavily rely on steel squares for layout work, which involves marking reference lines, centerlines, and other dimensions on metal pieces. The square's straight edges and precise measurements make it an ideal tool for ensuring accuracy in layout tasks. 3. Squareness checking: Metal components' squareness or perpendicularity can be determined using steel squares. By placing the square against a flat surface and checking for perfect edge alignment, metalworkers can assess if adjustments need to be made to achieve squareness. 4. Machinery setup: Precise alignment is crucial for metalworking equipment like milling machines, lathes, and drill presses. Steel squares are used to ensure these machines are set up at a perfect right angle to the workpiece, guaranteeing proper positioning. 5. Flatness inspection: When working with flat metal surfaces, it is essential to ensure they are level and flat. Steel squares are employed to check the flatness of metal sheets, plates, or workbenches. By placing the square's edge against the surface and observing any gaps or deviations, metalworkers can assess flatness. 6. Angle marking: Steel squares often come with additional features such as protractors or adjustable heads, enabling the marking and measurement of various angles. This is particularly useful when working with metal components that require specific angled cuts or bends. 7. Guiding cuts and welds: Steel squares are utilized by metalworkers to guide cutting tools like saws or plasma cutters along straight lines. By aligning the square's edge with the desired cut line, precise and accurate cuts can be achieved. Similarly, the square can also guide welds, ensuring straight and even weld lines. In conclusion, the steel square is an indispensable tool in metalworking due to its accuracy, versatility, and reliability. It allows metalworkers to achieve precision in measurements, layout work, and various metal fabrication tasks, ultimately leading to high-quality end products.

- Q: How do you use a steel square to lay out a circle?

- To use a steel square to lay out a circle, you would first determine the desired diameter of the circle. Then, locate the center point of the circle and anchor the steel square at this point. Next, extend the blade of the square to the desired radius, ensuring it remains perpendicular to the base. Finally, rotate the square around the center point while marking points along the circumference at regular intervals to complete the layout of the circle.

- Q: Can a steel square be used for welding?

- Indeed, welding can make use of a steel square. A steel square, known for its versatility, is frequently utilized in welding tasks to guarantee precise measurements and right angles. It serves as a guiding tool to thoroughly inspect the alignment and squareness of weld joints, ensuring their proper placement and welding at a 90-degree angle. Moreover, a steel square can be employed to measure and mark materials before cutting or welding, guaranteeing meticulous dimensions. In summary, a steel square plays a vital role in the welding process as it assists in attaining top-notch and precise welds.

- Q: Can a steel square be used for checking the squareness of countertops?

- A steel square can be used for checking the squareness of countertops. A steel square is a versatile tool that is commonly used in carpentry and construction to ensure accurate right angles. When checking the squareness of countertops, a steel square can be placed against the edge of the countertop to see if it forms a perfect 90-degree angle. If the countertop is square, the steel square will align perfectly with the edge, confirming its squareness. However, it is important to note that the steel square should be properly calibrated and in good condition to ensure accurate measurements. Additionally, other tools like a level or measuring tape could also be helpful in assessing the squareness of countertops.

- Q: Can a steel square be used for measuring angles in masonry work?

- No, a steel square is not typically used for measuring angles in masonry work. Masonry work usually requires specialized tools like a mason's square or a protractor specifically designed for measuring angles in this field.

- Q: How do you use a steel square to measure board thicknesses?

- To use a steel square to measure board thicknesses, you can follow these steps: 1. Start by selecting a steel square that has a tongue and a blade of the appropriate length. The tongue is the shorter side, while the blade is the longer side. 2. Place the steel square on a flat surface, ensuring that both the tongue and blade are flat against the surface. 3. Take the board you want to measure and place one edge against the tongue of the steel square, keeping it perpendicular to the square. 4. Slide the board along the square until its opposite edge rests against the blade. Make sure the board remains flat against the surface. 5. Take note of the measurement where the board's edge meets the blade of the steel square. This measurement represents the thickness of the board. 6. Repeat the process at different spots along the board's length to ensure a consistent thickness measurement. If there are any variations, use the average measurement for accuracy. Using a steel square to measure board thicknesses is a simple and effective method that provides accurate results.

- Q: Can a steel square be used for tile accent layout?

- Yes, a steel square can be used for tile accent layout. A steel square, also known as a framing square or carpenter's square, is a versatile tool that can be used for various layout and measurement tasks in construction, including tile work. Its L-shaped design and right angles allow for precise and accurate measurements, making it suitable for creating straight lines and angles needed for tile accent layout. However, it's important to note that a steel square should be used in conjunction with other tools, such as a level and chalk line, to ensure the tiles are positioned correctly and evenly.

- Q: Can a steel square be used for checking the plumbness of a beam?

- No, a steel square cannot be used for checking the plumbness of a beam. A steel square, also known as a framing square, is a tool primarily used for measuring and marking right angles. It is not designed or calibrated for measuring plumbness. To check the plumbness of a beam, a level or plumb bob should be used. A level is a tool with a bubble vial that indicates if a surface is vertical or horizontal, while a plumb bob is a weighted string that hangs vertically to determine a true vertical line. These tools are specifically designed for checking plumbness and provide more accurate results than a steel square.

- Q: How do you use a steel square to measure the height of a wall opening?

- To use a steel square to measure the height of a wall opening, you would first need to ensure that the steel square is squared. This means making sure that the edges are perpendicular to each other. Once you have a squared steel square, follow these steps: 1. Position the steel square against the wall, placing the long side vertically against the wall and the shorter side horizontally at the bottom of the opening. 2. Slide the steel square up or down until the shorter side is aligned with the bottom of the wall opening. 3. Hold the steel square firmly against the wall to maintain its position. 4. Look at the graduations or markings on the vertical side of the steel square. These markings represent the units of measurement (inches, centimeters, etc.). 5. Locate the graduation that aligns with the top edge of the wall opening. This will indicate the height of the opening. 6. Take note of the measurement displayed on the steel square, which represents the height of the wall opening. It's important to remember to keep the steel square level and maintain a firm grip to prevent any movement that may affect the accuracy of the measurement. Additionally, make sure to read the measurements properly and double-check your calculations to ensure accurate results.

Send your message to us

Steel Billet in Square Straight Form Big Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords