Hot Rolled Carbon Steel Square Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Square Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Product Advantages:

OKorder's Square Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Grade: Q195, Q235, Q345

2. Diameter: 6mm-150mm

3. Length: 6m, 9m, 12m or as customer’s request

4. Tolerance: Within ±5% for weight; ±2mm for diameter

5. Note: The price can be better is the quantity is good

6. Chemical composition

Alloy No | Element (%) | ||||

C | Mn | S | P | Si | |

Q195 | 0.06-0.12 | 0.25 | ≤0.05 | ≤0.045 | ≤0.3 |

Q235 | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Q345 | ≤0.2 | 1.00-1.60 | ≤0.045 | ≤0.045 | ≤0.55 |

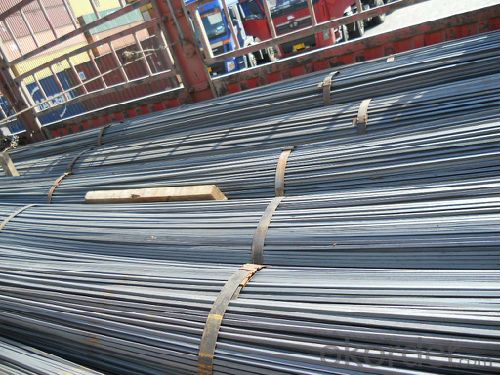

Packaging & Delivery of Steel Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Images:

- Q: How do you use a steel square to find the height of a retaining wall?

- In order to determine the height of a retaining wall using a steel square, several measurements and a basic understanding of the tool are necessary. The first step is to ensure that the steel square is clean and in good condition. To begin, position yourself near the retaining wall where you have a clear view of the top. Hold the steel square vertically, with the shorter side against the wall and the longer side extending upward. Align the square's bottom edge with the base of the wall. Next, measure the distance from the bottom edge of the steel square to the top of the retaining wall. This can be done by either extending your arm or using a measuring tape. It is important to keep the square perpendicular to the ground in order to obtain an accurate measurement. Once the measurement is obtained, write it down. This distance represents the height of the retaining wall and can be used for various purposes, such as calculating the necessary materials for repairs or assessing the wall's stability. It is crucial to emphasize the importance of accuracy when using a steel square to determine the height of a retaining wall. Take your time to ensure that the square is properly aligned and that your measurements are precise. Additionally, it is always beneficial to double-check your calculations and measurements to avoid any mistakes.

- Q: How is a steel square different from a regular square?

- The steel square, also referred to as a framing square or rafter square, possesses distinctive qualities and characteristics that distinguish it from a typical square. To begin with, the steel square is composed of robust and resilient steel, which grants it greater endurance and longevity in comparison to its wooden or plastic counterparts. This disparity in materials empowers the steel square to endure rigorous usage, withstand harsh conditions, and sustain its accuracy over an extended period. Furthermore, the steel square exhibits a distinctive design that sets it apart from a regular square. Typically, it consists of two arms: a lengthier one known as the body and a shorter one called the tongue. These arms intersect at a precise 90-degree angle, forming the characteristic "L" shape. The body of the steel square frequently incorporates diverse measurements and markings, including inches, centimeters, and angles. Consequently, this facilitates precise measurements and calculations essential in construction and carpentry endeavors. Moreover, the steel square often incorporates supplementary features that enhance its functionality. These may include a level vial, scribe bar, and notches for determining roof pitches and angles. These additional elements augment the versatility of the steel square, rendering it a valuable tool for layout, marking, and measurement in various construction and woodworking applications. In conclusion, the steel square distinguishes itself from a standard square through its material composition, as it is forged from steel to guarantee durability. Additionally, its unique design and supplemental features make it ideal for precise measurements and calculations essential in construction and carpentry work.

- Q: What is the purpose of the lip or flange on a steel square?

- The purpose of the lip or flange on a steel square is to provide a reference edge that can be used for marking lines or making accurate measurements. This lip or flange is typically perpendicular to the body of the square, allowing it to be aligned with the edge of a workpiece. By sliding the lip along the edge of the material, it ensures that the square is properly aligned and allows for precise marking or measuring. This feature is especially useful in woodworking, metalworking, and other trades where accuracy is crucial. Additionally, the lip or flange can also be used as a stop or guide when making repetitive cuts or layouts, further enhancing its functionality. Overall, the lip or flange on a steel square serves to improve the precision and efficiency of various tasks in different industries.

- Q: As for steel structure steel, how appropriate

- The size of the material is strongly related to the load on your floor, and the roof material and column size are also related to your span and the local Blizzard loads. You can choose the size of the material according to the local conditions.

- Q: How accurate are steel squares for measuring?

- Steel squares are known for their high accuracy in measuring. Due to their sturdy construction and precise right-angle edges, they offer reliable measurements for various applications.

- Q: Can a steel square be used for fence gate installation?

- Yes, a steel square can be used for fence gate installation. A steel square, also known as a framing square, is a versatile tool commonly used in carpentry and construction projects. It is typically made of steel and has a 90-degree angle and various measurements marked along its edges. When installing a fence gate, a steel square can be used to ensure accurate and precise measurements and angles. It can assist in determining if the gate is square, meaning that all sides are equal and the corners are at 90-degree angles. This is important for the gate to function properly and fit securely within the fence. A steel square can also be used to mark and measure the placement of hinges and other gate hardware. By aligning the square along the gate's edges, one can easily mark the desired locations for hinges, latch, and handle installation. Additionally, a steel square can be utilized to check the levelness of the gate during installation. By placing the square vertically against the gate, one can determine if it is plumb (perfectly vertical) or if adjustments are needed. Overall, a steel square is a valuable tool for fence gate installation as it ensures precision, accuracy, and proper alignment. It can greatly assist in achieving a well-built and functional gate that enhances the security and aesthetic appeal of the fence.

- Q: What are some common mistakes to avoid when reading measurements on a steel square?

- Some common mistakes to avoid when reading measurements on a steel square include misinterpreting the markings or graduations, not aligning the square properly with the object being measured, failing to account for any wear or damage on the square, and not using the appropriate side or edge for the specific measurement required.

- Q: How do you use a steel square to determine the angle of a tapering cut?

- To determine the angle of a tapering cut using a steel square, follow these steps: 1. Position the steel square on the material you wish to cut, ensuring that one side aligns with the material's edge. 2. Draw a line alongside the steel square's edge, parallel to the material's edge, using a pencil or marker. 3. Slide the steel square along the material while maintaining alignment with the edge. 4. Observe the point where the drawn line begins to deviate from the material's edge as you slide the square. This deviation indicates the tapering angle. 5. Take note of the distance between the original line and the point of deviation. This measurement will assist in determining the tapering angle. 6. Measure the angle using a protractor, specialized taper jig, or refer to a tapering angle chart, based on the noted distance. Alternatively, utilize a digital angle finder tool. Remember that using a steel square may not provide the same precision as specialized tools for determining tapering angles. It is advisable to verify measurements and perform test cuts on scrap material before proceeding with your actual project.

- Q: Can a steel square be used for checking the squareness of a table saw fence?

- Yes, a steel square can be used for checking the squareness of a table saw fence. A steel square, also known as a carpenter's square or framing square, is a tool with a right-angle shape that can be used to ensure that the edges and corners of a workpiece or tool are perfectly square. To check the squareness of a table saw fence, simply place the steel square against the fence and align it with the blade of the table saw. If the square is properly aligned, the blade should be perpendicular to the fence, indicating that the fence is square. However, it is important to note that while a steel square can provide a quick and easy way to check squareness, it is always recommended to use a more precise measuring tool, such as a dial indicator or precision square, for accurate results.

- Q: How do you use a steel square to find the slope of a ramp?

- To use a steel square to find the slope of a ramp, place one leg of the square on the ramp surface and align the other leg vertically. Then, measure the vertical distance from the ground to the top of the square's vertical leg. This measurement represents the rise of the ramp. Next, measure the horizontal distance from the top of the ramp to the square's horizontal leg. This measurement represents the run of the ramp. Finally, divide the rise by the run and multiply by 100 to obtain the slope as a percentage.

Send your message to us

Hot Rolled Carbon Steel Square Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords