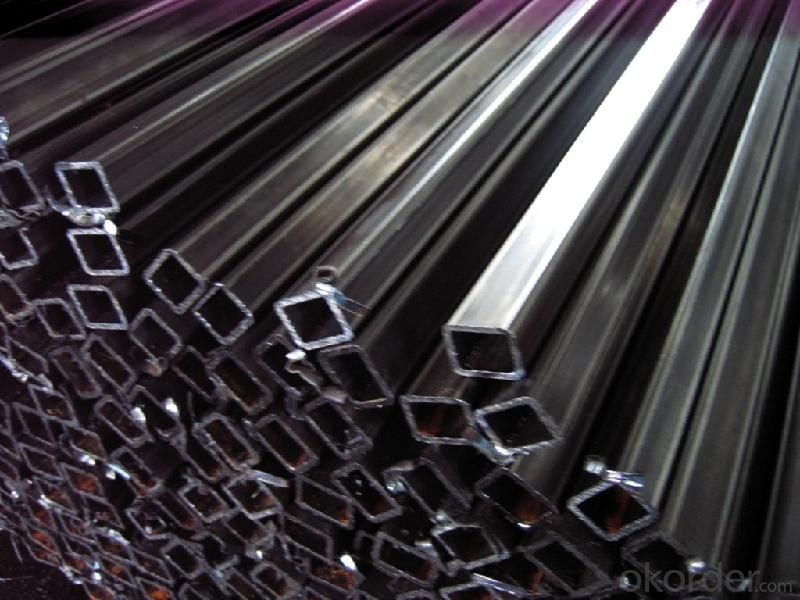

12mm*1.13kg/m square bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

We offer Square Steel Bar with grade Q195 / Q235

Specifications of Square Steel Bar:

-Standard: GB,

-Grade: Q195/Q235 or equivalent.

Chemical Composition:

-Chemical Composition. Q195

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 | ||

-Chemical Composition. Q235

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures and Tolerances of Square Steel Bar:

(The section of Square Steel Bar)

-The length of a side and the theoretical weight of Square Steel.

Length of a side(a, mm) | Theoretical weight(kg/m) | Length of a side(a, mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Usage/Applications of Steel Square Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of Steel Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Payment:

-Invoicing on theoretical weight or actual weight a s customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

- Q: How do you use a steel square for creating precise dado cuts?

- To use a steel square for creating precise dado cuts, you need to follow a few steps. First, ensure that your steel square is clean and free from any rust or debris that could affect its accuracy. Next, mark the precise location of the dado cut on your workpiece using a pencil or marking knife. Make sure to measure and mark the width and depth of the dado accurately. Now, place the steel square on the marked line, aligning one edge of the square with the edge of your workpiece. Ensure that the square is held firmly against the workpiece to prevent any movement. With the steel square in position, use a sharp utility knife or chisel to score along the edge of the square, marking the entire length of the dado. This scoring helps define the boundaries of the dado and provides a guide for the subsequent steps. Once the scoring is complete, remove the steel square and use a saw or router to cut along the scored line, ensuring that the blade or bit stays within the marked boundaries. Take your time and make slow, controlled cuts to maintain precision. After the dado has been cut, use a chisel or router to remove any excess material within the dado, ensuring that it matches the desired width and depth. You can use the steel square again to check the accuracy of the final cut. Remember to always prioritize safety when working with tools and follow the manufacturer's instructions for the specific tools you are using. Practice and patience are essential in achieving precise dado cuts, so don't rush the process and take your time to ensure accuracy.

- Q: How do you use a steel square to find the height of a fence post?

- To use a steel square to find the height of a fence post, you will need to follow a few steps. First, ensure that the steel square is squared off and level. Place one edge of the steel square against the side of the fence post, making sure it is flush with the post's surface. Next, use the measurements on the steel square to determine the height of the fence post. Most steel squares have measurements marked along the edges, typically in inches or centimeters. Locate the measurement that corresponds to the desired height. Once you have identified the correct measurement on the steel square, align a straight edge (such as a ruler or another piece of wood) with the measurement on the square. Make sure the straight edge is perpendicular to the ground and extends vertically from the top edge of the square. Hold the straight edge firmly in place and extend it upwards until it reaches the desired height of the fence post. Now, you can mark the spot on the straight edge where it intersects with the top of the post. This mark represents the height of the fence post. You can then use this mark as a reference point to cut the fence post to the desired height or to ensure that all the posts are at the same height. Remember to double-check your measurements and ensure that the steel square is level and properly aligned for accurate results.

- Q: How do you use a steel square for marking stair stringers?

- To use a steel square for marking stair stringers, you will need to follow a few steps. First, determine the total rise and run of your stairway. The rise refers to the vertical height from the floor to the top of the landing or upper floor, while the run represents the horizontal distance from the front edge of one step to the next. Once you have these measurements, place the steel square on the edge of a piece of lumber that will serve as the stringer. Align the long edge of the square with the edge of the lumber, ensuring that the shorter arm of the square is pointing towards the top of the stringer. Next, use the rise and run measurements to mark the stringer. For the rise, locate the corresponding number on the steel square's long edge and draw a line across the lumber. This line represents the top of each step. For the run, locate the measurement on the shorter arm of the square and draw a line parallel to the top line you just marked. This line represents the front edge of each step. Continue this process for each step, using the same measurements for rise and run throughout. Make sure to double-check your measurements and ensure they are consistent to ensure a level and properly aligned stairway. Once you have marked all the steps on the stringer, use a circular saw or a handsaw to cut along the marked lines. Take your time and cut carefully, as accuracy is crucial for a safe and stable stairway. Finally, test fit the stringer in place to ensure it fits properly. Make any necessary adjustments if needed before proceeding with the installation of the stairs. Using a steel square for marking stair stringers may take some practice, but once you become familiar with the process, it becomes a reliable and efficient method for accurately marking and cutting stringers.

- Q: Can a steel square be used for marking out dovetail joints?

- Yes, a steel square can be used for marking out dovetail joints. A steel square is a versatile tool commonly used in woodworking for measuring, marking, and checking the accuracy of right angles. When marking out dovetail joints, precision and accuracy are crucial, and a steel square can provide the necessary reference for ensuring the correct angles and dimensions are achieved. By aligning the square along the edges of the workpiece, it can help guide the marking of the dovetail angles and provide a straight edge for accurate cutting. However, it is important to note that while a steel square can be a useful tool, it is recommended to also use a dovetail marking gauge or a dovetail template to ensure the best results and maintain consistency throughout the project.

- Q: Is there a specific method for using a steel square correctly?

- Using a steel square correctly requires a specific method. A steel square, which is also known as a framing square or carpenter's square, is a versatile tool used in woodworking and carpentry for measuring, marking, and guiding straight, square, and angled lines. To ensure proper usage of a steel square, follow these steps: 1. Get acquainted with the different parts: A steel square consists of two arms, a body, and a tongue. The arms typically measure 24 inches in length, while the body and tongue form a right angle. The body is the longer side, while the tongue is the shorter one. 2. Verify accuracy: Prior to using the steel square, it is essential to check if it is correctly calibrated and accurate. Inspect the edges for any damage or wear that may affect its precision. 3. Make straight markings: To mark a straight line, position the body of the square against the material's edge that you are working with. Align the edge of the material with the desired measurement mark on the square's body. Securely hold the square in place and draw a line along the tongue. 4. Make square markings: For marking a square or a 90-degree angle, align the body of the square against one edge of the material. Steadily hold the square in place and draw a line along the tongue. Next, rotate the square 90 degrees and align the body against the adjacent edge. Draw a line along the tongue intersecting the previous line. The point of intersection indicates a perfect square. 5. Measure and mark angles: Steel squares often have degree markings on the body and tongue, enabling you to measure and mark specific angles. Align the square accordingly, using the degree markings as a guide, and mark the desired angle on your material. 6. Check for squareness: A steel square can also be utilized to ascertain if a corner or joint is square. Position the body of the square against one edge of the corner and the tongue against the other. If the square fits perfectly, the corner is square. If there is a gap, the corner is not square and may require adjustment. Remember to use a pencil or a marking tool with a fine point to ensure accurate markings. Additionally, take your time, apply firm but gentle pressure, and double-check your measurements to ensure precision. Practicing and gaining experience will enhance your proficiency in correctly using a steel square.

- Q: Can a steel square be used for checking the squareness of a picture frame miter joint?

- No, a steel square cannot be used for checking the squareness of a picture frame miter joint. A miter joint requires a specialized tool such as a miter square or a miter gauge to accurately check and ensure the squareness of the joint.

- Q: Can a steel square be used for measuring and marking compound miter and bevel cuts?

- Yes, a steel square can be used for measuring and marking compound miter and bevel cuts. While a steel square is typically used for measuring and marking right angles, it can also be used to measure and mark angles for compound miter and bevel cuts. By using the measurements and angles provided by the steel square, you can accurately mark the cuts on your material before making them. However, it is important to note that for more precise and complex compound miter and bevel cuts, specialized tools like a miter saw or a bevel gauge may be necessary.

- Q: Can a steel square be used for door installation?

- Door installation can indeed make use of a steel square. Known by various names such as a framing square or carpenter's square, this versatile tool is commonly employed by carpenters and builders for a multitude of tasks, including door installation. Its primary function is to ensure that the door frame is both square and level, a crucial aspect of proper installation. By placing the steel square against the frame, one can easily assess the corners for squareness. Additionally, it can be utilized for marking and measuring the hinge mortises and other significant points throughout the installation process. Hence, a steel square is an indispensable tool that greatly aids in achieving a professional and precise door installation.

- Q: Can a steel square be used for checking the alignment of deck boards?

- Yes, a steel square can be used for checking the alignment of deck boards. The straight edges and right angles of a steel square make it a suitable tool for ensuring that the deck boards are properly aligned.

- Q: Can a steel square be used for furniture-making projects?

- Yes, a steel square can be used for furniture-making projects. Steel squares are versatile and durable tools that can be used for measuring, marking, and checking angles in woodworking projects. They provide accurate and precise measurements, ensuring the furniture pieces are built with precision and accuracy.

Send your message to us

12mm*1.13kg/m square bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords