Stainless Steel Slabs In Best Selling Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

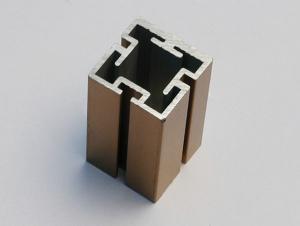

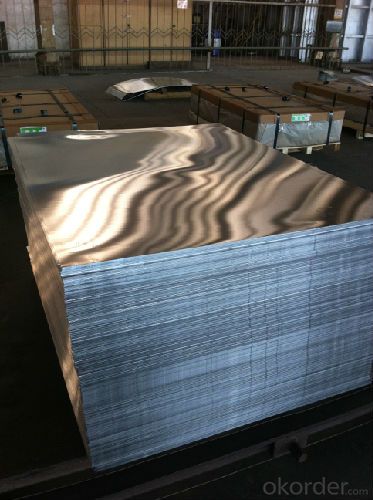

1.Structure of Product Description

we can produce stainless steel sheet, whose name are called Cold rolled sheet, hot rolled checkered sheet, cold rolled mirror finished sheet are all widely used in the field of construction field and decoration field, etc. There are many different grades, such as:

201, 202, 301, 304, 316, 410, 420, 430, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are stainless steel sheet, stainless steel coil, stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: Can stainless steel sheets be used for decorative purposes?

- Yes, stainless steel sheets can definitely be used for decorative purposes. Stainless steel is known for its sleek and modern appearance, making it a popular choice for various decorative applications. It is often used in interior design, architecture, and even art installations. Stainless steel sheets can be customized to create unique patterns, textures, and finishes, making them suitable for creating eye-catching and visually appealing decorative elements. Additionally, stainless steel is highly durable, corrosion-resistant, and easy to maintain, making it a practical choice for both indoor and outdoor decorative applications.

- Q: 304 why is stainless steel magnetic?

- However, due to segregation or improper heat treatment during smelting, there will be a small amount of martensite or ferrite in Austenitic 304 stainless steel. In this way, 304 stainless steel will have a weak magnetic.

- Q: What are the different welding techniques used for stainless steel sheets?

- Various welding techniques are commonly employed for stainless steel sheets, each offering distinct advantages and considerations. 1. TIG Welding (Gas Tungsten Arc Welding): TIG welding, a versatile and precise method, proves suitable for thin stainless steel sheets. It involves using a non-consumable tungsten electrode to generate an electric arc that melts and fuses the metals. High-quality welds with minimal heat distortion and excellent aesthetic appearance are ensured. 2. MIG Welding (Gas Metal Arc Welding): MIG welding, known for its efficiency and user-friendliness, is a popular choice for stainless steel sheets. It employs a consumable electrode wire and an inert gas shield to protect the weld from atmospheric contamination. MIG welding exhibits faster speed than TIG welding and performs well on thicker stainless steel sheets. 3. Spot Welding: Joining two stainless steel sheets together, spot welding applies pressure and heat using electrodes. This technique finds common use in applications where a continuous seam is unnecessary, such as in automotive manufacturing or appliance production. 4. Plasma Arc Welding: Similar to TIG welding, plasma arc welding employs a more concentrated arc produced by a constricted nozzle. This technique allows for deeper penetration on stainless steel sheets, making it suitable for thicker materials or specialized applications. 5. Laser Welding: Laser welding, a precise and rapid technique, employs a high-powered laser beam to melt and join stainless steel sheets. It offers exceptional control over the welding process and proves suitable for thin to medium thickness stainless steel sheets. However, laser welding may require specialized equipment and expertise. The choice of welding technique depends on various factors, including the thickness of the stainless steel sheets, desired weld quality, production speed, and equipment availability. Each technique possesses its own advantages and limitations.

- Q: Can stainless steel sheets be used in outdoor environments?

- Yes, stainless steel sheets can be used in outdoor environments. Stainless steel is highly resistant to corrosion, making it a suitable choice for outdoor applications where exposure to moisture, humidity, and other environmental elements is likely.

- Q: What are the different types of stainless steel sheet patterns?

- There are several different types of stainless steel sheet patterns, including plain, diamond, honeycomb, chequered, and linen. These patterns offer various aesthetic options for different applications and design preferences.

- Q: Can stainless steel sheets be used for food preparation surfaces?

- Food preparation surfaces can indeed utilize stainless steel sheets. The reason behind stainless steel's popularity for such surfaces is its remarkable characteristics. Being non-porous, it avoids the absorption of any liquids or bacteria that can contaminate the food. Moreover, stainless steel exhibits resistance to corrosion, staining, and rusting, thereby ensuring its durability and longevity for food preparation surfaces. Furthermore, stainless steel can be easily cleaned due to its ability to withstand high temperatures and resistance to most cleaning agents. This fact makes it a hygienic option for food preparation surfaces, as it allows for thorough sanitization to prevent bacterial growth. In conclusion, stainless steel sheets provide a secure and practical alternative for food preparation surfaces.

- Q: What are the benefits of using mirror-finish stainless steel sheets?

- Mirror-finish stainless steel sheets offer numerous advantages in various applications. Firstly, their mirror-like surface adds elegance and style to any space, whether it be in interior design, architecture, or decorative pieces. The reflective nature of the mirror finish enhances the overall aesthetic appeal. Furthermore, these sheets are exceptionally durable and long-lasting. The high-quality stainless steel material used in their production ensures resistance to corrosion, rust, and staining, making them suitable for both indoor and outdoor use. This quality also makes them easy to clean and maintain, saving time and effort in upkeep. In addition, mirror-finish stainless steel sheets have the ability to reflect light, making them ideal for spaces that require enhanced lighting or where light distribution is important. The reflective surface helps brighten up the environment, making it perfect for areas such as kitchens, bathrooms, and commercial spaces. Moreover, these sheets are highly versatile and can be used in a wide range of applications. From kitchen countertops and backsplashes to wall claddings, elevator interiors, and even custom-made furniture, their versatility allows for creative and unique designs in various industries. Furthermore, mirror-finish stainless steel sheets have excellent heat resistance properties, making them suitable for applications involving high temperatures. This feature makes them a popular choice in commercial kitchens, industrial settings, and other environments where heat exposure is a concern. Lastly, mirror-finish stainless steel sheets are an environmentally friendly option. Stainless steel is highly recyclable, and using mirror-finish sheets promotes sustainability by reducing the need for new materials. This aligns with the growing emphasis on eco-friendly practices and the desire to reduce the carbon footprint. In conclusion, the advantages of mirror-finish stainless steel sheets include their elegant appearance, durability, light reflection capabilities, versatility, heat resistance, and eco-friendliness. These qualities make them a desirable choice for various applications, providing both aesthetic appeal and functional advantages.

- Q: How do you form stainless steel sheets into different shapes?

- Stainless steel sheets can be formed into different shapes through various processes such as bending, rolling, and welding. The specific method used depends on the desired shape and the thickness of the stainless steel sheet. Bending is a common method used to form stainless steel sheets into shapes such as cylinders or boxes. This process involves clamping the sheet between a punch and a die and applying force to create the desired bend. The angle and radius of the bend can be controlled by adjusting the pressure and the distance between the punch and die. Rolling is another technique employed to form stainless steel sheets into curved or cylindrical shapes. This process involves passing the sheet through a set of rollers, which gradually bend the material into the desired shape. The diameter and curvature of the final shape can be adjusted by changing the spacing and alignment of the rollers. For more complex shapes, welding is often used in conjunction with bending or rolling. In this process, multiple stainless steel sheets are joined together using heat and pressure to create the desired form. This allows for the creation of intricate shapes, such as cones or irregular geometries. In addition to these methods, specialized equipment such as hydraulic presses or hydroforming can also be utilized to form stainless steel sheets into different shapes. These techniques involve applying high pressure or fluid pressure to the sheet, resulting in deformation and the desired shape. It is important to note that forming stainless steel sheets requires skilled operators and precise machinery to ensure accuracy and quality. Additionally, the properties of the stainless steel, such as its thickness and composition, can also influence the feasibility and success of the forming process.

- Q: What drill can drill stainless steel?

- Carbide bit: a drill used in core drilling. The cylindrical steel bit is named after the carbide cutting tool with tungsten carbide. The shape of cemented carbide cutting tools, the number of them arranged on the drill bit, the arrangement and the welding angle are called the bottom, the inner edge and the outer edge, so as to ensure the clearance between the water and the powder. The upper part of the drill body is threaded connection tube, a drill bit body are arranged at the side part of the sink, the bottom surface is provided with a nozzle lip. Both the water tank and the water inlet ensure the circulation of the washing fluid, so as to eliminate the influence of the rock powder and the cooling bit. When drilling into the clay and shale formations, the ribs are welded to the inner and outer sides of the hard alloy drill bit in order to increase the gap, called the rib bit. Self drilling bits with needle like carbide can be used in hard formations with high abrasive properties. Rock drillability is a grade II VII formation general hard alloy drilling; acicular carbide drill drilling a rock grade VI viii.

- Q: Is the cold rolled steel plate good or the stainless steel plate?

- The cold rolled steel itself, whether washed by acid car wash, semi-finished products, or rolled out by cold rolling mill semi-finished products, their rust resistance is very poor. It is easy to oxidize, resulting in rust on the surface of the air. It will not rust until it has been plated with aluminum or zinc, and it is clear that the process is complex and unsafe.

Send your message to us

Stainless Steel Slabs In Best Selling Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords