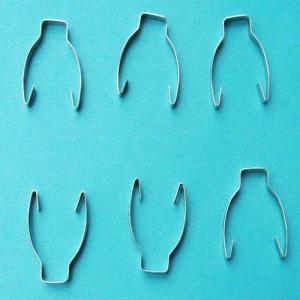

Stainless Steel Sheet Metal Fabrication with Zinc Plating

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000pieces pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details Of Sheet Metal Fabrication and Assembly

| Brand Name | MOULDSZ |

| Material | Stainless steel, iron , aluminum alloy, red copper, brass, bronze alloy are available. |

| Quality Control | ISO9001:2008 |

| MOQ | 2000pcs |

Specification Of Sheet Metal Fabrication and Assembly

| Material | Stainless steel, iron ( SPCC, SECC, SPTE, tinplate), aluminum alloy, red copper, brass, bronze alloy are available. |

| Surface Treatment | Powder coating, zinc plate ,polish |

| workshop for mnufacture | CNC Laser Cutting ,Stamping, Punching , Bending, turning ,Welding, roll-in, surface treatment, and other General Fabrication Service |

| processing center | Stamping machine; Rolling machine; Turning machine; Milling machine; Grinding machine |

| Workmanship for manufacturing | CNC Laser Cutting ,Stamping, Punching , Bending, turning ,Welding, roll-in, surface treatment, and other General Fabrication Service |

Our Advantage For Sheet Metal Fabrication and Assembly

1. Handling components of very tight tolerance and very complex geometry

2. Low MOQ (1pc is even acceptable in some special conditions)

3. Offering free and quick prototyping ( normally 1 week)

4. Delivery on time

5. Top quality guaranteed by skilled workers, managing system and status of facilities.

6. A series of secondary service available, like casting; forging; welding; heat treatment etc.

7. Offering consultancy service on components machining

8. Customized size and spec /OEM available

9. Near Ningbo and Shanghai, convenient transportation

Packaging & Delivery Of Sheet Metal Fabrication and Assembly

1.Packaging:with the pallet or do as your need .

2.Delivery : according to your order quantity .

- Q: I work as a graphic designer. Now I work for a company that processes mold parts and has been doing it for a year. I think it's time to change jobs

- I do not know your drawing specific job is to do what someone else is good design, you are tracing or your own design drawing. If only tracing words, I think it is no future and dull as ditch water. If you design it, it's very different. You say you've only been working for a year, and I don't know if you can design for yourself. Overall, the future of mold design is still very large. At present, the level of mold production in our country is not very high, and there is still a distance from the international level, although China's mold industry has made rapid changes in recent years. I have seen a micro gear, you need to use 500 times the magnifying glass to see the gear, but such a small gear, you can not imagine the injection molding machine, you can imagine the difficulty of mold production. The mold design is the foundation, often related to product quality, production efficiency, you die before design, must fully understand the processing technology, product quality requirements, combined with the technology to design their own mold in the field of good to die. So I suggest that you make more efforts in this area and you will make some achievements.

- Q: What are the differences and connections between die design and mechanical design?

- Mold design for the school's professional is almost the same, learning mechanical design can also learn mold design second professional, learning mold design, but also need to learn the knowledge of mechanical design. The range of mechanical design including the relatively wide, want to learn is very difficult, we must rely on the work experience, to exercise their own, mold design is professional, learning is easier to learn, but only rely on mold design learning is insufficient. Likewise, experience is the most important

- Q: What is the flow of mold design?

- Process, design, and then do foam, casting, processing, and then assembly, and finally the debugger

- Q: I am reading materials, molding and control engineering, the choice is the direction of mold processing, and no one can say how the employment direction?

- Material forming and Control Engineering (molding, processing and die CAD/CAM)Objective: to cultivate with metal and plastic materials such as product, process and mould knowledge, can use computer technology to product, process and mould design, the use of CNC machining technology for mould manufacturing, senior engineering and technical personnel engaged in product and mold test, production management, sales and other aspects of the.Main courses: metal forming technology and mold, plastic molding process and mold design, decoration and plastic products, mold materials and heat treatment, mold manufacturing, CNC machining technology, product design, mold computer aided design (CAD), mold computer aided manufacturing (CAM), computer aided analysis of molding process, molding (CAE) equipment and computer control, innovative design, mold, mold production management and marketing.Employment direction: Computer Aided Design in metal mold and plastic products, technology and related materials processing engineering in various industries, computer aided manufacturing, NC machining, test development, quality inspection analysis, management of marketing, education and scientific research work.

- Q: Mould design and manufacture. It's no use learning it. Hurry up! Who will introduce you?

- Want to learn mold design and manufacturing, the mold must be a certain understanding of the structure, it is best to do, and then to learn the design

- Q: How should numerical control be combined with mold design?

- I think people should first learn the basic knowledge of numerical control and die,If you want to combine, the most important thing is to learn the processing technology, but at least know how a part should have what kind of process.The most convenient thing is to learn some mainstream modeling software, such as UG, PROE and so on.Take UG as an example, the software itself has modeling modules and process modulesThe correct modeling can be introduced into NC machining center, and the parts can be machined automatically by UG programming.This in itself is a way of combining modeling with numerical control

- Q: Which is more important, UG or CAD, in die design?

- Damn good, dare to even CAD and the importance of UG do not know that UG is fine.There is a CAD fast, I think you are wrong, CAD is not out of the map fast, it is easy to learn the map, so for ordinary people, CAD feel faster.

- Q: What is the relationship between industrial design and mold design and manufacturing?

- Industrial design is divided into art and engineering, art is product form design, engineering is similar to mechanical design. Mold design is a branch of mechanical design, more is how to achieve the product, how to produce problems! For example, the handle plastic parts, industrial design and design, shape, mold design, the pattern of the shape of the mold design and production, and then the design of the mold for mass production.Industrial Design (Industrial Design), referred to as ID design. The design of industrial products on the basis of engineering, aesthetics and economics.Industrial design into product design, environmental design, communication design, design management 4 categories; including design, mechanical design, circuit design, costume design, environmental planning, interior design, architectural design, UI design, graphic design, packaging design, advertising design, animation design, display design, website design etc.. Industrial design is also called industrial product design. Industrial design involves psychology, sociology, aesthetics, ergonomics, mechanical construction, photography, color science and so on. Industrial design and industrial division of labor brought about by industrial design, and other arts, production activities, process production are obviously different, it is a variety of disciplines, technology and aesthetic concepts of the cross product.Mold design and manufacturing refers to the mold processing technology and production and maintenance. When the ability to achieve, you can also do the design, the main design drawings.

- Q: Am I allowed to skip the process and die as a mold designer? I have been working for a month and have a good knowledge of the machining process

- I suggest you should do the processing for a period of time, because the basis of die design or manufacture of all kinds of parts should be very familiar with, there is ambition is a good thing, but to lay a good foundation, can be done in the processing at the same time, more attention, how to design out needed to pursue the parts, you can also in my spare time in learning to say, maybe one day you'll find that you have no need to apprentice, and can be designed and manufactured!

- Q: Does material forming and processing involve mold design and manufacturing?

- This major includes welding, casting, forging, and moulds and so on

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2.5 Million - US$ 5 Million |

| Main Markets | Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central, America, Northern Europe, Southern Europe, South Asia, Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | less than 50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | about 500 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Stainless Steel Sheet Metal Fabrication with Zinc Plating

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000pieces pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords