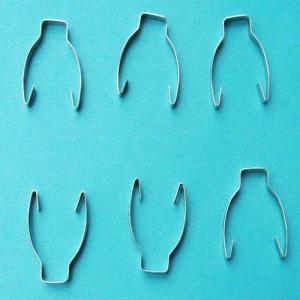

High Precision Stainless steel Copper Casting

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Copper Casting

| Brand Name | MOULDDD |

| Place of Origin | Liaoning, China( Mainland) |

| Material | Copper Alloy, Brass, Bronze |

| Finish | Polishing, Ball shotting, Painting, Zinc Painting,sand blast, etc |

| Technology | Precision casting, precision machining |

| OEM Service | Acceptable |

Specification of Copper Casting

| Casting Process | Clay sand casting, furan resin sand casting, shell mold casting; Water-glass sand casting, water-glass investment casting, lost-wax investment casting; Die casting, sand casting, lost-wax casting. |

Application | Machinery part,/Casting/Tractor/Pump Valve/Impeller/Electrical equipment/Auto parts/ Farm machinery/Railway equipment/Mining machinery/Engineering machinery/ Petroleum machinery etc. |

| Equipment | CMM. CNC X-Ray |

| Dimensions | According to customer request |

| Certificate | ISO9001:2000 |

| Inspection | Mechinical Property Inspection |

Usage&Application

Machinery part,/Casting/Tractor/Pump Valve/Impeller/Electrical equipment/Auto parts/

Farm machinery/Railway equipment/Mining machinery/Engineering machinery/

Petroleum machinery etc.

Packing&Delivery

Packing Details: inner cartons and outer wooden box.

Delivery Details: 30 days after order confimationa and deposite.

- Q: Which is good for mold design and manufacture and software?

- In fact, we ignore, CATIA is the most powerful, but not yet universal. CATIA will definitely exceed UG PROE later

- Q: I work as a graphic designer. Now I work for a company that processes mold parts and has been doing it for a year. I think it's time to change jobs

- I do not know your drawing specific job is to do what someone else is good design, you are tracing or your own design drawing. If only tracing words, I think it is no future and dull as ditch water. If you design it, it's very different. You say you've only been working for a year, and I don't know if you can design for yourself. Overall, the future of mold design is still very large. At present, the level of mold production in our country is not very high, and there is still a distance from the international level, although China's mold industry has made rapid changes in recent years. I have seen a micro gear, you need to use 500 times the magnifying glass to see the gear, but such a small gear, you can not imagine the injection molding machine, you can imagine the difficulty of mold production. The mold design is the foundation, often related to product quality, production efficiency, you die before design, must fully understand the processing technology, product quality requirements, combined with the technology to design their own mold in the field of good to die. So I suggest that you make more efforts in this area and you will make some achievements.

- Q: What is the flow of mold design?

- A question is hard to say in strict terms. Every factory has the tactics of each factory! A set of mold also has a lot of design methods, but also depends on manufacturers requirements, product quality requirements and die prices!

- Q: How about the employment prospects of mold design and manufacturing?

- According to the relevant person in charge, die students are not completed, there are many enterprises competing to book, in advance with students to negotiate. So far, the minimum monthly salary of enterprises is 3000 yuan, in the past there are die industry experience students, many enterprises were 100 thousand yuan annual salary, hired Dongguan senior mold talents, annual salary of 100 thousand. The latest news from the talent market in Dongguan, Dongguan, at least 3000 senior mould talent shortage, a trained in PRO/E, UG and other aspects of work experience in mold design, mold manufacturing and technical personnel, often more than 100 thousand yuan annual salary.

- Q: What is the difference between mold design and mold manufacturing? Hard to learn?

- The design is to draw the shape of the mold on paper or computer, and use two-dimensional images to express the three-dimensional mold. Manufacturing is the process of drawing a mold on a paper or computer by a lathe. Better spatial imagination! And junior high school does not matter, a lot of things you want to make up, or it is easy to fill.

- Q: I want to teach myself the die design (plastic mould). Please tell me which books I need. What's the title of the book? I'd like to have more details. Thank you

- Buy the foundation of the book, look at the institutions, plastic mold forming and technology, I suggest you do mold apprentice, that can be theory and practice together

- Q: Attention should be paid to improvements in die design as well as improvements in EDM

- Simple to say, the design should pay attention to, such as the spark discharge part, is must pay attention to, such as checking a place to play deep, will the performance of carbon, copper and crude public young male, how much is the gap between coarse and fine. Is conducive to the scene is; playing time is in the middle of the fight or unilateral into the number of dozen; copper public square Taiwan, when playing, you can also subsection play, the size of the current! And so on ~ also does not understand, leaves a message me, is discussing!

- Q: please some Mold professionals enter!

- CATIA application enterprise is not many, not to study, unless can find the mold enterprise with this software.These are the most useful professional skills, you see, your lifestyle, combined with your type of work, your interests and direction of development elective. Make a timetable on the line, I wish you an early talent yadong!

- Q: What's the meaning of the "section difference" in the die design?

- Mold design refers to the digital design enterprises engaged in mold, including mold and die, based on the traditional mold design, the full application of digital design tools, improve the quality of mold design, shorten the period of mould design. The mold is a kind of industrial product material forming the structure specific through a certain way, but also be able to mass produce a production tool with industry parts of a certain shape and size requirements. As large as airplanes, cars, small cups and nails, almost all industrial products must be molded by moulds. The high precision, high consistency and high productivity of the parts produced by the mould are incomparable to any other processing methods. Mold to a large extent determine the quality of products, benefits and new product development capabilities.

- Q: The mould making and designing is more promising than the mechanical drawing (mechanical processing technician)

- Of course, mold making and design of the industry is promising, my brother-in-law is 26 years old this year, he was studying to be a mold design and production, the work in the company now, ten thousand 51 months, just as long as he is the design of the machine and sold a two thousand or three thousand Commission ```````` proposal making and design mold

1. Manufacturer Overview

| Location | Liaoning, China |

| Year Established | 2011 |

| Annual Output Value | Above US$ 10 Million - US$ 50 Million |

| Main Markets | the United States, Germany, Japan, EU and other countries, the majority of users praise and love. |

| Company Certifications | ISO 9001:2008 PED Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% - 40% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 1,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Precision Stainless steel Copper Casting

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords