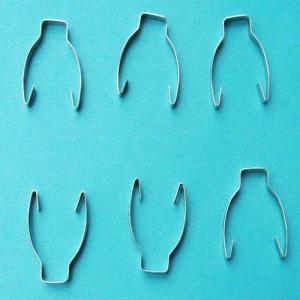

Steel Precision Casting Part with Stainless

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details Of Stainless Steel Precision Casting Part

| Brand Name | MOULDDD | Material | Stainless steel ,cast iron, pig iron, carbon steel |

| Surface | polishing, machining, plating | Type | lost wax casting, soluble glass casting, ductile iron casting, sand casting, die-casting |

| Qaulity Control | ISO 9001TS16949 certified for auto parts industry | OEM | We can supply OEM |

Specifications Of Stainless Steel Precision Casting Part

| Material | stainless steel, cast iron, pig iron, carbon steel, alloy steel, non-ferrous, grey iron, ductile cast iron,etc |

| Surface | polishing, machining, plating, Heat Treatment, painting,ect. |

| Type | lost wax casting, soluble glass casting, ductile iron casting, sand casting, die-casting,cnc machining ,ect |

| Process | 1) Process: Die Casting + Machining 2)Secondary Machining: CNC turning, milling, drilling, grinding, assembly to Packing 3) Surface Finish: Chrome plating, sandblasting, painting, anodizing, powder coating, electrophoresis |

| Test Equipment | 1) Hardness tester,2) Chemical analysis,3) Digital Measuring Projector , 4) Dynamic Balancing Tester,5) Universal testing machine & Coordinate-Detector |

| Quality Control | ISO 9001 TS16949 certified for auto parts industry |

| Packing | With The Wooden Pallet |

Application Of Stainless Steel Precision Casting Part

Industrial parts, Machinery parts, construction parts, valve parts, train, craft, door handle, hinge, hydraulic pressure, construction, agricultural machinery, auto parts,ect.

Packaging /Delivery Of Stainless Steel Precision Casting Part

Packaging: with the wooden pallet or do according to customers' need

Delivery:do according to order quantity .

- Q: Which is good for mold design and manufacture and software?

- Pro-E and UG are pretty good. We used these two when we were at school.

- Q: How to enter the mold industry?

- It's good to study for six months under the master gate

- Q: Plastic mould design and NC programming

- I did the mold for more than four years, I suggest you do mold designMold programming is very simple, general learning professional software will be able to, such as UG, Cimatron and MasterCAM can be solved, coupled with point processing experience on it.Mold design requires a stronger professional knowledge, but also to see your qualifications, do better mold design, and later looking for work, certainly much higher than programming,Of course, to do the design, programming, processing, processing arrangements to understand a little bit of it, or else you design things, others can not be processed, there is no way, huh, huhFor others that wages are thousands and thousands to see your ability to see you in private or European companies, to see you looking for a job when the economic environment and so on factors determining your salary or salary, do not look at the money now, you can work hard, don't listen to not understand the people have to get thousands of thousands of for you, is not practical, if you enter the good points of the European and American enterprises do automobile manufacturing company, believe that you may have the salary of thousands of.8K you might also look down on, oh

- Q: I am reading materials, molding and control engineering, the choice is the direction of mold processing, and no one can say how the employment direction?

- Material forming and Control Engineering (material processing, control and information technology)Objective: to cultivate the basic principle of material processing, computer control and information science knowledge and skills, master the material forming process automation and artificial intelligence, expert information system establishment and development, mechanical parts and tooling of the computer aided design and manufacturing, new materials preparation and processing, advanced forming technology and equipment the structure and properties of materials, analysis and control of professional knowledge, to senior engineering and technical personnel engaged in material processing, computer and information technology application in the field of product and technology development, design and manufacturing, quality control, management and other aspects.Main courses: Fundamentals of materials science, material forming principle, material structure and properties of computer numerical control principle, advanced materials processing technology, surface engineering, modern materials aided design and manufacturing, mold CAD/CAM, computer simulation technology, control engineering and numerical control principle and programming, testing technology and control engineering and computer network and expert information the application, in material processing and material processing enterprise computer management information system, material processing quality analysis and control, micro analysis and computer image processing.

- Q: What are the majors of NC machining and die design? Specific point

- Very practical professional, can not bear hardships of children, do not learn.. The future will enter the company very hard, worked with oil, machine, iron... However, 5~6 years of children, the community is very popular, the monthly salary is easy to pass 8000~1 million, belong to difficult to recruit technical jobs... It doesn't matter if you don't answer Ben. Don't waste that money.. I'm in this major.

- Q: What is the best die design software available at the moment?

- That depends on what kind of mold. We use UG for car moulds. I think it's good!

- Q: What basic knowledge do CNC milling machine software programming and mold design require? Where do you start learning?

- It is recommended to operate machine tools first, and then to study!

- Q: What's the future of the mold?

- Learning a skill will at least be respected. The older the industry, the more valuable it is

- Q: The mould making and designing is more promising than the mechanical drawing (mechanical processing technician)

- Of course, mold making and design of the industry is promising, my brother-in-law is 26 years old this year, he was studying to be a mold design and production, the work in the company now, ten thousand 51 months, just as long as he is the design of the machine and sold a two thousand or three thousand Commission ```````` proposal making and design mold

- Q: Stamping die design and manufacturing thinking and exercises, mold processing relative to the general parts of what features?

- The production of moulds is small, and most of them have the characteristics of single production.

1. Manufacturer Overview

| Location | Liaoning, China |

| Year Established | 2011 |

| Annual Output Value | Above US$ 10 Million - US$ 50 Million |

| Main Markets | the United States, Germany, Japan, EU and other countries, the majority of users praise and love. |

| Company Certifications | ISO 9001:2008 PED Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% - 40% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 1,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Steel Precision Casting Part with Stainless

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords