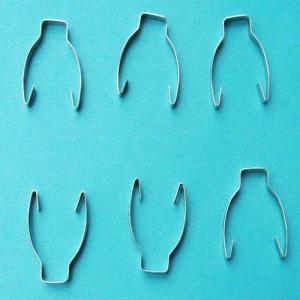

Sheet Metal Multi-Function High Precision Stamped Shrapnel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000pieces pc

- Supply Capability:

- 20000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details Of High Precision Stamped Shrapnel

| Brand Name | MOULDSZ |

| Material | Brass, Stainless steel, BeCu, Carbon steel, bronze, Alloy spring steel, etc. |

| MOQ | 5000pcs |

Specification Of High Precision Stampd Shrapnel

| Material | Brass, Stainless steel, BeCu, Carbon steel, bronze, Alloy spring steel, etc |

| Mould | According customers request to build the mould. |

| Surface treatment | Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, and imitation gold-plated |

| Equipment | High-speed punching machines,Ordinary punching machines,Wire cutting machines,Milling machines ,etc |

Application Of High Precision Staped Shrapnel

Our products are widely used in many files , such as cellphone ,cumputer,switch ,lights ,communication devices ,auto parts etc.

Packaging & Delivery Of High Precision Staped Shrapnel

1.Packaging:with wooden case after fumigation or according to customer's requirement.

2.Delivery : according to your order quantity .

- Q: Which is good for mold design and manufacture and software?

- I think AutoCAD is more convenient for two-dimensional graphics, Pro/E and UG tend to be more three-dimensional, and the two can also be converted into CAD format. For Pro/E, UG, the two can be converted, specifically with what kind of software, look at the kind of software you use the company, the south side of the UG used more

- Q: CAD die file for die pressing die design

- Then look at the mold design manual and get an assembly plan. It's about the same shape.

- Q: What are the differences and connections between die design and mechanical design?

- Mold design for the school's professional is almost the same, learning mechanical design can also learn mold design second professional, learning mold design, but also need to learn the knowledge of mechanical design. The range of mechanical design including the relatively wide, want to learn is very difficult, we must rely on the work experience, to exercise their own, mold design is professional, learning is easier to learn, but only rely on mold design learning is insufficient. Likewise, experience is the most important

- Q: What is the difference between mould design speciality and material molding specialty?

- The former is the focus of the mold, the latter emphasis is molding, more emphasis on material properties

- Q: I am reading materials, molding and control engineering, the choice is the direction of mold processing, and no one can say how the employment direction?

- Metal material engineeringObjective: to cultivate a basic knowledge of materials science and engineering and in advanced metal materials and inorganic non-metallic materials, energy and environmental materials, composite functional materials are engaged in the design, processing and other aspects of technology and management personnel; engaged in new materials and new technology research and development personnel; personnel engaged in composite products, quality inspection the inspection and management of senior.Main courses: mechanical drawing and design, physical chemistry, material science, basic principle, material processing material corrosion and surface technology, material properties, heat treatment of materials, energy engineering, energy materials, environmental materials, inorganic non-metallic materials, functional materials, composite materials, nano materials, materials of modern detection technology, process and die design, computer aided design, electrical and electronic technology, enterprise management, graduation design and thesis.

- Q: I am a fresh undergraduate student. I have just learned how to deal with the die design. How about the treatment? Do you know what to say?

- Pretty good, so much software! In addition, you have learned the most two kinds of software used in mold design: UG, proe. Just, you have more software, but also understand the role of each chart in the software! There will be great difficulty in applying him to his work! After all, there is no relevant work experience! And this experience can only be learned from the work, there are free to download some relevant information online, groping at home! In this way, learning may also be faster!You can also search for Nantong science education network where there are a lot of data of mold, there is also a free video! Learn to learn first.

- Q: What is the difference between mold design and mold manufacturing? Hard to learn?

- Simply speaking, mold design is based on the products to be processed to design mold; mold manufacturing is based on the design drawings required to mold out. Need to have basic knowledge of mechanical design of the general mold design (including the basic knowledge of engineering mechanics, mechanical drawing, technology, computer aided design and mold processing etc.), so the mold manufacturing can be said is the foundation of design. Mold manufacturing is relatively simple, at present, a higher degree of automation of mechanical processing, mainly to learn all kinds of machine tools, operations and mechanical basic knowledge (mechanical drawings, processes, etc.). As for your fear that nothing can be learned, it is impossible, as long as you work hard, you can still learn.

- Q: please some Mold professionals enter!

- CATIA application enterprise is not many, not to study, unless can find the mold enterprise with this software.These are the most useful professional skills, you see, your lifestyle, combined with your type of work, your interests and direction of development elective. Make a timetable on the line, I wish you an early talent yadong!

- Q: How should numerical control be combined with mold design?

- Now there are many schools opened a mold CAD/CAM professional, that is specifically for your needs, I also learn this profession, but later diverted to do CNC machining.Software, a lot of choice, there are UG/PROE/CATIA/MASTERCAM/AUTOCAD/SOLID, EDGE, and so on, only one, you can recommend UG and CATIA

- Q: What is the relationship between industrial design and mold design and manufacturing?

- I don't know. Do you know what this is all about?...

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2.5 Million - US$ 5 Million |

| Main Markets | Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central, America, Northern Europe, Southern Europe, South Asia, Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | less than 50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | about 500 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Sheet Metal Multi-Function High Precision Stamped Shrapnel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000pieces pc

- Supply Capability:

- 20000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches