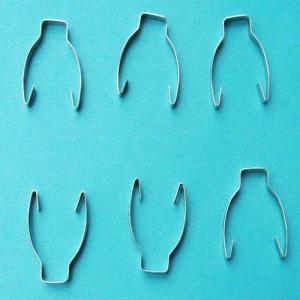

Metal Mould Sheet for Industrial Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500Piece set

- Supply Capability:

- 2000000Piece/Pieces Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details Of Sheet Metal Mould

| Brand | MOULDSZ | Material | stainless steel sheet ,alluminium sheet |

| Surface | Chrome Plating, Sandblasting, Painting | MOQ | 500pcs |

Specifications Of Sheet Metal Mould

| Material | stainless steel, cast iron, pig iron, carbon steel, alloy steel, non-ferrous, grey iron, ductile cast iron,etc |

| Surface | polishing, machining, plating, Heat Treatment, painting,ect |

| Processing | Die Casting + Machining |

| Machine | 1) 350T-1800T aluminum die casting machinery 2) CNC milling and turning, grinding, honing, lapping, broaching and other secondary machining. 3) integral CNC machineries & four machining centers, such as milling, broaching, drilling, turning, planning, grinding machinery and three-axle machining centers. |

| Sndard | OEM manufacturing as per customers requirements or drawings |

Application Of Sheet Metal Mould

Industrial parts, Machinery parts, construction parts, valve parts, train, craft, door handle, hinge, hydraulic pressure, construction, agricultural machinery, auto parts,ect.

Packaging /Delivery Of Sheet Metal Mould

packaging:with the wooden pallet or do according to customers' need

Delivery :according to customers' order quantity

- Q: CAD die file for die pressing die design

- CAD drawing file for pressing die designHow do you plan your specific parameters?,I'm fine

- Q: About die design and machining

- Mold design to understand the processing technology, that is feasible, there are optimization, not designed, can be processed or easy to process. Therefore, mold design must be a little understanding of mechanical processing, milling, milling, grinding, CNC, EDM, WE, etc., if you learn mechanical processing, from above to pick a school. PS designed to pay low, the office comfortable, long-term plan, it is recommended to learn this.... Processing, tired, but can be described as a craft. General companies do three years to do the competent, but also boil through, and wages are almost the same.

- Q: What are the prospects for NC machining and die design and manufacture?

- These two kinds of learning are very promising. NC manufacturing is a necessary step is very general, the employment market of CNC machine operator great demand, especially to programming and design of complex workpiece process, tooling and fixture design of NC technology personnel are more outstanding for many manufacturing enterprises. Mold design and manufacturing is another big direction of the manufacturing industry, such as die-casting mold, extrusion die, injection mold technicians are very popular. The automobile engine can not be separated from the die casting mould; the high-speed train, the subway and the building profile can not be separated from the extrusion die; the plastic product, such as the toy, can not be separated from the injection mould.

- Q: What are the necessary skills in mold design and manufacturing?

- Personally, the design requires a wealth of mechanical knowledge, such as metal materials, mechanical coordination, engineering mechanics, mechanical manufacturing, and so on. Manufacturing must have extensive experience in machining and fitter assembly.

- Q: What does "2D" in the die design mean? What is the main idea?

- That is to do 2D die plan. To show all the parts through the 2D plane view, to see if there is interference in each part, whether the position is reasonable or not. It will save a lot of things to start 3D.

- Q: What basic knowledge do CNC milling machine software programming and mold design require? Where do you start learning?

- It is recommended to operate machine tools first, and then to study!

- Q: Attention should be paid to improvements in die design as well as improvements in EDM

- 1, consult an experienced colleague and ask which one is critical;2, find some related books, manuals, such as the bookstore to find;3, with the on-site operation master (experience to be rich, good) chat, in the heart of humbly ask for help (Note way);4, the best way is to come straight to the point, seriously with an open mind (if you dislike, at least pretend to be) directly to consult for you to arrange the task, then he will tell you off the reel.These can be emergency, but also in the future reference, for reference purposes only.

- Q: How should numerical control be combined with mold design?

- Now there are many schools opened a mold CAD/CAM professional, that is specifically for your needs, I also learn this profession, but later diverted to do CNC machining.Software, a lot of choice, there are UG/PROE/CATIA/MASTERCAM/AUTOCAD/SOLID, EDGE, and so on, only one, you can recommend UG and CATIA

- Q: What is the relationship between industrial design and mold design and manufacturing?

- I don't know. Do you know what this is all about?...

- Q: What's the meaning of the "section difference" in the die design?

- Mold design refers to the digital design enterprises engaged in mold, including mold and die, based on the traditional mold design, the full application of digital design tools, improve the quality of mold design, shorten the period of mould design. The mold is a kind of industrial product material forming the structure specific through a certain way, but also be able to mass produce a production tool with industry parts of a certain shape and size requirements. As large as airplanes, cars, small cups and nails, almost all industrial products must be molded by moulds. The high precision, high consistency and high productivity of the parts produced by the mould are incomparable to any other processing methods. Mold to a large extent determine the quality of products, benefits and new product development capabilities.

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2.5 Million - US$ 5 Million |

| Main Markets | Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central, America, Northern Europe, Southern Europe, South Asia, Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | less than 50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | about 500 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Metal Mould Sheet for Industrial Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500Piece set

- Supply Capability:

- 2000000Piece/Pieces Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords