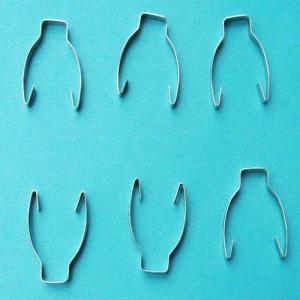

High Quality Drawing Design Small Size Sand Casting Vending Machine Parts

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details Of Small Size Casting Vending Machine Parts

| Brand Name | MOULDDD | Material | Grey Iron ,aluminum A380 |

| Surface | Chrome Plating, Sandblasting | Weight | 0.5kg to 2000kg |

Specifications Of Small Size Casting Vending Machine Parts

| Material | Grey Iron aluminum A380, A390, ADC12 |

| Surface | Chrome Plating, Sandblasting, Painting, Powder Coating, Anodizing |

| Weight | 0.5kg to 2000kg |

| Processing | Resin sand or Furan Resin Sand and green sand |

| Main Market | South America, North America, Europe, Southeast Asia, Mid East |

| Certificate | ISO 9001:2008, RoHs Test Report |

Application Of Small Size Casting Vending Machine Parts

Auto Parts, Furniture Parts, Pump Parts, Machinery Parts, Light fittings etc...

Packaging /Delivery Of Small Size Casting Vending Machine Parts

Packaging: with the wooden pallet or do as customers' need

Delivery: do according to the order quantity

- Q: Which is good for mold design and manufacture and software?

- I think AutoCAD is more convenient for two-dimensional graphics, Pro/E and UG tend to be more three-dimensional, and the two can also be converted into CAD format. For Pro/E, UG, the two can be converted, specifically with what kind of software, look at the kind of software you use the company, the south side of the UG used more

- Q: CAD die file for die pressing die design

- CAD drawing file for pressing die designHow do you plan your specific parameters?,I'm fine

- Q: About die design and machining

- Mold design to understand the processing technology, that is feasible, there are optimization, not designed, can be processed or easy to process. Therefore, mold design must be a little understanding of mechanical processing, milling, milling, grinding, CNC, EDM, WE, etc., if you learn mechanical processing, from above to pick a school. PS designed to pay low, the office comfortable, long-term plan, it is recommended to learn this.... Processing, tired, but can be described as a craft. General companies do three years to do the competent, but also boil through, and wages are almost the same.

- Q: Plastic mould design and NC programming

- After graduation, do NC programming firstBasically Cimatron and MasterCAM software, programming with moreUG programming super slowThe reason is that the mold design must understand the processingNC programming CNC is the most critical partAt the same time programming to learn PRO/E or UG a go dieThen, when you have the opportunity to do mold design, you can reflect the processing capacityOf course, it's a long processWe here mold design, 5K processing, 3K two will be 8KIf the product structure design is also combined, of course, as well as the appearance of product performanceThat's the sprint to 20W

- Q: What are the majors of NC machining and die design? Specific point

- Out, you can programming CNC, you can operate CNC, you can do fitter, you can do mold design. But it all starts with internships and apprenticeships. Good luck。

- Q: What are the necessary skills in mold design and manufacturing?

- Personally, the design requires a wealth of mechanical knowledge, such as metal materials, mechanical coordination, engineering mechanics, mechanical manufacturing, and so on. Manufacturing must have extensive experience in machining and fitter assembly.

- Q: What is the difference between mold design and mold manufacturing? Hard to learn?

- Well, to tell you, the mold design is the design model, made by the mold maker, according to the model Depends on your interest, interest, learning is easy.

- Q: Mold design department, the general service department to find suppliers outside processing, but the general do not understand mold design, only to find lower prices suppliers, because suppliers are general affairs

- First of all, the design section has the right to use the mold design. In the intellectual property right, you have copyright.

- Q: Am I allowed to skip the process and die as a mold designer? I have been working for a month and have a good knowledge of the machining process

- I worked for 3 years to design the mold fitter, but now only understand software design, tooling and processing but to know very little, really useful is still on processing and mold design, software is just a gadget that saw executives very proficient in software, there is hope to help you

- Q: What do the mould design assistant engineers need to know? Master, do me a favor!

- You have to understand a lot of places, in front of me, you are rookie, assistant is not necessarily someoneYou have to have a strong 3D key modeYou have to have a high 3D partingYou have to have good group 2D standing upYou have to understand the processing procedures, design in line with the actualOh, these you will, you can take charge as chief of personnel.

MOULDDD produced a wide range of products, applied to the valve, electrical equipment, automobile parts, agricultural machinery, railway equipment, mining machinery, engineering machinery, petroleum machinery and other fields. Customers' special design and process requirements, will receive meet the company's products exported to the United States, Germany, Japan, EU and other countries, the majority of users praise and love.

1. Manufacturer Overview

| Location | Liaoning, China |

| Year Established | 2011 |

| Annual Output Value | Above US$ 10 Million - US$ 50 Million |

| Main Markets | the United States, Germany, Japan, EU and other countries, the majority of users praise and love. |

| Company Certifications | ISO 9001:2008 PED Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% - 40% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 1,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Drawing Design Small Size Sand Casting Vending Machine Parts

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches