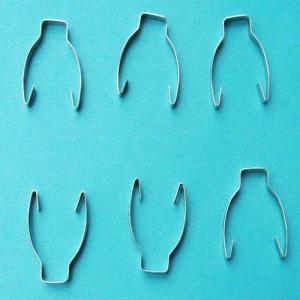

High Quality 100% Ductile Iron Casting Parts

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Ductile Iron Casting Parts

| Brand Name | MOULDDD |

| Place of Origin | Liaoning, China( Mainland) |

| Material | Gray & Ductile Iron |

| Finish | Natural Color |

| Technology | Silica Sol,compound die for the shell process,casting technology of watglass in our Precision casting workshop: we also have resin sand casting process water glass process in our sand workshop. |

| OEM Service | Acceptable |

Specification of Ductile Iron Casting Parts

| Casting Process | Clay sand casting, furan resin sand casting, shell mold casting; Water-glass sand casting, water-glass investment casting, lost-wax investment casting; Die casting, sand casting, lost-wax casting. |

Application | Machinery part,/Casting/Tractor/Pump Valve/Impeller/Electrical equipment/Auto parts/ Farm machinery/Railway equipment/Mining machinery/Engineering machinery/ Petroleum machinery etc. |

| Equipment | CMM. CNC X-Ray |

| Dimensions | According to customer request |

| Certificate | ISO9001:2000, Mill Certificate |

| Inspection | Mechinical Property Inspection |

Usage&Application

Machinery part,/Casting/Tractor/Pump Valve/Impeller/Electrical equipment/Auto parts/

Farm machinery/Railway equipment/Mining machinery/Engineering machinery/

Petroleum machinery etc.

Packing&Delivery

Packing Details: inner cartons and outer wooden box.

Delivery Details: 30 days after order confimationa and deposite.

- Q: Which is good for mold design and manufacture and software?

- I think AutoCAD is more convenient for two-dimensional graphics, Pro/E and UG tend to be more three-dimensional, and the two can also be converted into CAD format. For Pro/E, UG, the two can be converted, specifically with what kind of software, look at the kind of software you use the company, the south side of the UG used more

- Q: What are the requirements for a mold design?

- Many people ask these questions, the mold design is not clear in two words or three. I can only say briefly here.1, understand the mold structure.General hardware mold and plastic mold two is in the majority, two kinds of mold structure is very different. I do hardware2 、 drawing softwareAt the very least, a two-dimensional and a three-dimensional, two-dimensional, such as CAD, three-dimensional, such as PROE, in addition to UG, SOLIWORK, etc., UG, PROE is the mainstream. I'm using PROE3, understand the processing technology, the whole set of mold is how to process out? For example, what kind of machine is used? What's the order in the sequence?4, understand the mold work, forming principle, for example, to become the shape and size, how to design its parts drawing, and how to assemble this part on the mold? Wait, a lotOthers rely on experience, and can not speak at once, after all, is a technical activity. Remember: experience is very importantAskThank you for your answer, but I do the injection mould

- Q: In the processing and design of the mold, the quadrilateral and the single side of that advantage, where are there?

- If the processing equipment is of higher precision, use a single number, so that the assembly of the whole set of molds will be higher precision. Because the accuracy of the equipment is not enough, it is used to offset part of the error.

- Q: What are the differences and connections between die design and mechanical design?

- Mold design and mechanical design are all mechanical design areas, the key to learn mechanical drawing, metal materials and heat treatment, theoretical mechanics and materials mechanics of these basic courses. Mechanical design is widely used, mold design is relatively more professional, more widely used, there are many categories, there are stamping drawing die, die-casting mold, injection mold, metal casting mold, cold extrusion die, forging die and so on. As a beginner, it is necessary to learn the basic knowledge well and practice in the factory. We can improve the theory we have learned in practice.

- Q: What are the commonly used software for die design?

- Unigraphics (referred to as UG) entered the mainland much later than PRO-E, but it is also the most advanced and high-end CAD/CAE/CAM software for manufacturing industry in the world today. UG software has been used by many of the world's leading manufacturers in industrial design, detailed mechanical design, and engineering. Today, UG has more than 17000 customers around the world. UG has been developing rapidly since entering the Chinese market in 90 years. It has become the first choice software in the fields of automobile, machinery, computer and home appliance, mould design, etc..Roughly PRO-ENGINEER, UG, AUTOCAD, MoldflowThe first two are 3D software, which can be used for sketch drawing, part making, assembly design, sheet metal design, processing and so on, so that users can choose and use according to their own needs. The biggest difference between the two should be parameterization.AUTOCAD is used for two-dimensional drawing, detailed drawing, design documents and basic 3D design.Moldflow is an analysis softwareThe design scheme can be simulated, evaluated and optimized. Reduce potential design mistakes, shorten product development cycle and reduce development cost

- Q: Mould design and manufacture. It's no use learning it. Hurry up! Who will introduce you?

- It can be said to be useful, but it can also be said to be useless!Useful well, these are common sense, should understand, understand the day after work is very helpful!Say no use, the knowledge is too common, the level of use is still a great distance!

- Q: What is the best die design software available at the moment?

- UG is mainly suitable for large cars and aircraft factories to build complex digital models, while PRO/E is mainly suitable for small and medium enterprises to rapidly build simpler digital models. In the more complex modeling, it is often no parameter is useful, I generally use PRO/E to start a relatively simple line frame, curved surface, and then go to UG inside the advanced surface of the establishment, chamfering. Most of the parameters have been deleted because of repeated changes to the product. The two software has its own advantages, and it should be mixed modeling to achieve the best results. When the parts are larger and more complex, the processing is done in UG, Cimatron, roughing and UG finishing.

- Q: How should numerical control be combined with mold design?

- Fundamentals: engineering drawings, processed materials, cutting tools, mechanical design fundamentals, engineering mechanics, cold die foundations, plastic mold foundations, CNC machining and processes, etc..

- Q: PLC programming in mold design and automation control

- All very well! There is no absolute good Human effort is the decisive factor., industry, only do good people. I'm an automation!

- Q: Am I allowed to skip the process and die as a mold designer? I have been working for a month and have a good knowledge of the machining process

- I worked for 3 years to design the mold fitter, but now only understand software design, tooling and processing but to know very little, really useful is still on processing and mold design, software is just a gadget that saw executives very proficient in software, there is hope to help you

1. Manufacturer Overview

| Location | Liaoning, China |

| Year Established | 2011 |

| Annual Output Value | Above US$ 10 Million - US$ 50 Million |

| Main Markets | the United States, Germany, Japan, EU and other countries, the majority of users praise and love. |

| Company Certifications | ISO 9001:2008 PED Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% - 40% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 1,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality 100% Ductile Iron Casting Parts

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords