Stainless Steel Sheet Manufacturer with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/321/410/420/430/444/443/409L,and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

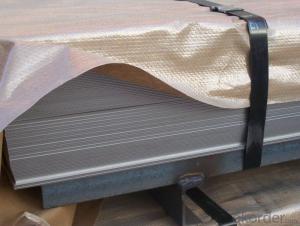

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Cold Rolled and Hot Rolled:

Packing and Loading:

FAQ:

1. What's the quality?

Very fine, we have been exported to more than 30 countries.

2. How long get reply?

Usually within 24 hours

If you have any question about stainless steel sheets, do not forget to send the email to us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What are the color options for stainless steel sheets?

- Stainless steel sheets generally come in a variety of color options, depending on the specific type of finish applied to the surface. The most common color options for stainless steel sheets include silver, which is the natural color of stainless steel, as well as black, gold, bronze, and copper. These colors are achieved through processes such as powder coating, PVD coating, or chemical treatments, which create a thin layer on the surface of the stainless steel sheet. The color options allow for greater versatility in design and can be chosen to complement different aesthetics and applications.

- Q: What are the different welding techniques used for stainless steel sheets?

- There are several welding techniques commonly used for stainless steel sheets, each with its own advantages and considerations. 1. TIG Welding (Gas Tungsten Arc Welding): TIG welding is a versatile and precise technique suitable for thin stainless steel sheets. It uses a non-consumable tungsten electrode to create an electric arc that melts and fuses the metals. TIG welding ensures high-quality welds with excellent aesthetic appearance and minimal heat distortion. 2. MIG Welding (Gas Metal Arc Welding): MIG welding is a popular technique for stainless steel sheets due to its efficiency and ease of use. It utilizes a consumable electrode wire and an inert gas shield to protect the weld from atmospheric contamination. MIG welding is faster than TIG welding and works well for thicker stainless steel sheets. 3. Spot Welding: Spot welding involves using electrodes to apply pressure and heat to join two stainless steel sheets together. This technique is commonly used in applications where a continuous seam is not required, such as for joining stainless steel sheets in automotive manufacturing or appliance production. 4. Plasma Arc Welding: Plasma arc welding is similar to TIG welding but uses a more concentrated arc produced by a constricted nozzle. This technique can achieve deeper penetration on stainless steel sheets and is often used for thicker materials or specialized applications. 5. Laser Welding: Laser welding is a precise and fast technique that uses a high-powered laser beam to melt and join the stainless steel sheets. It provides excellent control over the welding process and is suitable for thin to medium thickness stainless steel sheets. However, laser welding may require specialized equipment and expertise. Each welding technique has its own advantages and limitations, so the choice of technique depends on factors such as the thickness of the stainless steel sheets, desired weld quality, production speed, and available equipment.

- Q: Can stainless steel sheets be used in architectural applications?

- Yes, stainless steel sheets can be used in architectural applications. Stainless steel is a versatile material that offers durability, corrosion resistance, and aesthetic appeal, making it suitable for various architectural purposes such as cladding, roofing, decorative elements, and structural components. Its sleek, modern look and ability to withstand harsh environmental conditions make stainless steel sheets a popular choice in the construction industry.

- Q: What are the main chemical constituents of stainless steel plates?

- Stainless steel not only refers to a stainless steel, but more than one hundred kinds of industrial stainless steel, the development of each kind of stainless steel in its specific application areas have good performance. The key to success is to find out what the purpose is, and then determine the correct type of steel. There are usually only six kinds of steel related to the application of building construction. They all contain 17 to 22% chromium, and better steel also contains nickel. The addition of molybdenum can further improve atmospheric corrosion, especially for atmospheric corrosion resistant chlorides.

- Q: What are the different types of surface treatments for stainless steel sheets?

- There are several types of surface treatments for stainless steel sheets, including brushing, grinding, polishing, and coating. Brushing creates a textured finish, grinding removes imperfections, polishing enhances shine, and coating adds a layer of protection.

- Q: Are stainless steel sheets suitable for laboratory equipment or instruments?

- Yes, stainless steel sheets are highly suitable for laboratory equipment and instruments. Stainless steel is known for its excellent corrosion resistance, which is crucial in laboratory environments where equipment comes into contact with various chemicals and substances. It is also highly resistant to heat, making it suitable for use with high-temperature processes or sterilization procedures. Additionally, stainless steel is easy to clean and maintain, which is essential for maintaining a sterile and hygienic laboratory environment. The durability and strength of stainless steel make it ideal for withstanding heavy usage and ensuring long-lasting performance. Overall, stainless steel sheets are a reliable and popular choice for laboratory equipment and instruments due to their corrosion resistance, heat resistance, cleanliness, and durability.

- Q: Can stainless steel sheets be used for kitchen backsplashes?

- Yes, stainless steel sheets can be used for kitchen backsplashes. Stainless steel is a popular choice for kitchen backsplashes due to its durability, resistance to heat and moisture, and easy maintenance. It provides a sleek and modern look to the kitchen while also protecting the wall from splatters and stains. Additionally, stainless steel sheets are available in various finishes, such as brushed, mirrored, or patterned, allowing homeowners to choose the style that best complements their kitchen design.

- Q: What is the water absorption rate of stainless steel sheets?

- Stainless steel sheets have a typically very low or negligible rate of water absorption. Renowned for its superb corrosion resistance and impermeability to liquids, including water, stainless steel is extensively acknowledged. Thanks to its distinct composition and surface properties, water absorption and penetration into stainless steel sheets are not easily facilitated. Hence, stainless steel is favored for numerous moisture-sensitive applications, for instance, in the food and beverage sector, medical equipment, and outdoor structures.

- Q: What are the benefits of using embossed stainless steel sheets?

- There are several benefits of using embossed stainless steel sheets. Firstly, embossed stainless steel sheets offer enhanced aesthetic appeal. The embossed patterns on the surface of the stainless steel sheet add a unique texture and visual interest to any space. This can help to create a more visually appealing and modern look in both residential and commercial settings. Additionally, embossed stainless steel sheets provide increased durability and strength. Stainless steel is already known for its excellent resistance to corrosion, staining, and wear. The embossing process further enhances the strength and durability of the sheets, making them suitable for high traffic areas or areas where there is a risk of damage or impact. Another benefit of using embossed stainless steel sheets is their versatility. These sheets can be used in a wide range of applications, including wall cladding, elevator panels, kitchen backsplashes, furniture, and architectural features. They can be easily cut and shaped to fit different design requirements, making them a versatile choice for various projects. Furthermore, embossed stainless steel sheets are easy to clean and maintain. The smooth surface of the embossed patterns makes it easier to wipe away dirt, grime, and fingerprints, ensuring a clean and hygienic surface. This is especially beneficial in areas where cleanliness is a priority, such as kitchens or healthcare facilities. Lastly, embossed stainless steel sheets are environmentally friendly. Stainless steel is a highly sustainable material as it is 100% recyclable, and the embossing process does not generate any waste or harmful byproducts. This makes embossed stainless steel sheets an eco-friendly choice for those looking to reduce their carbon footprint and contribute to a greener environment. In conclusion, the benefits of using embossed stainless steel sheets include enhanced aesthetic appeal, increased durability and strength, versatility in applications, easy maintenance, and eco-friendliness. These sheets are a great choice for those seeking a durable, stylish, and sustainable material for their projects.

- Q: Are stainless steel sheets scratch resistant?

- Yes, stainless steel sheets are generally scratch resistant due to their composition and protective layer that helps prevent scratches from everyday use. However, it is important to note that excessive force or abrasive materials can still cause scratches on stainless steel surfaces.

Send your message to us

Stainless Steel Sheet Manufacturer with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords