CorrugatedStainless Steel Sheet with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/321/410/420/430/444/443/409L,and 904L.

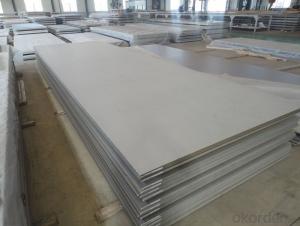

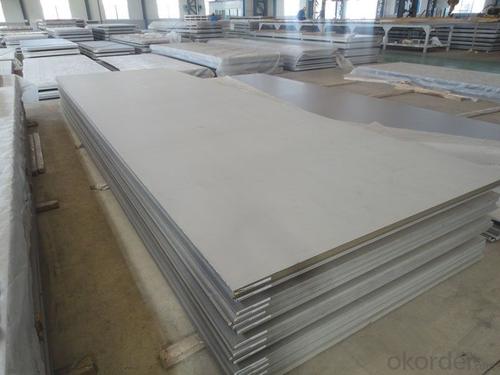

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

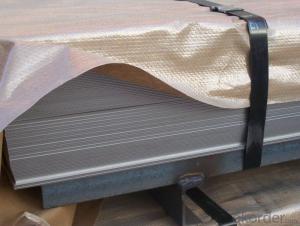

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

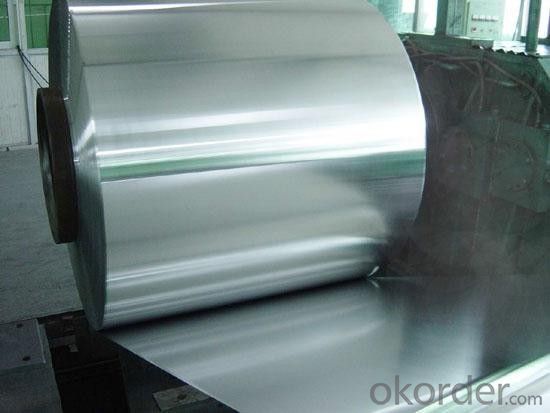

Cold Rolled and Hot Rolled:

Packing and Loading:

FAQ:

1. What's the quality?

Very fine, we have been exported to more than 30 countries.

2. How long get reply?

Usually within 24 hours

If you have any question about stainless steel sheets, do not forget to send the email to us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for hygienic environments?

- Stainless steel sheets are indeed suitable for hygienic environments. This is because stainless steel possesses certain inherent properties that render it highly resistant to corrosion, heat, and chemical damage, thus making it a popular choice for such environments. Its surface is smooth and non-porous, which facilitates easy cleaning and prevents the accumulation of bacteria, mold, or other contaminants. Furthermore, stainless steel is non-reactive and does not release any harmful substances, making it ideal for sensitive environments like food processing facilities, hospitals, pharmaceutical labs, and cleanrooms. Moreover, stainless steel is both durable and long-lasting, ensuring excellent hygiene and cleanliness for extended periods. All in all, stainless steel sheets are a dependable and hygienic option for various applications in environments that prioritize cleanliness and sanitation.

- Q: How do you remove rust or corrosion from stainless steel sheets?

- There are several effective methods to remove rust or corrosion from stainless steel sheets. One common approach is to use a mixture of baking soda and water to create a paste, which can be applied to the affected areas and gently scrubbed using a soft cloth or sponge. Another option is to use vinegar or lemon juice, which have natural acidic properties that can help dissolve the rust. Simply soak a cloth in either of the liquids and rub the affected areas until the rust is removed. For more stubborn rust or corrosion, using a commercial stainless steel cleaner or a fine-grit sandpaper can be effective. It is important to always follow the manufacturer's instructions and to test any cleaning method on a small, inconspicuous area before applying it to the entire surface.

- Q: Can stainless steel sheets be used for automotive body panels?

- Yes, stainless steel sheets can be used for automotive body panels. Stainless steel provides excellent corrosion resistance, durability, and aesthetic appeal, making it a suitable material for automotive applications.

- Q: What are the features of stainless steel plates?

- Can withstand oxalic acid, sulfuric acid iron sulfate, nitrate, nitrate acid and hydrofluoric acid, sulfuric acid copper sulfate, phosphoric acid, formic acid and acetic acid and various acid corrosion, widely used in chemical, food, medicine, papermaking, petroleum, atomic energy industry, as well as construction, kitchen utensils, cutlery, household appliances, vehicles of all kinds of parts.

- Q: What are the benefits of using embossed stainless steel sheets in elevator interiors?

- There are several benefits of using embossed stainless steel sheets in elevator interiors. Firstly, embossed stainless steel sheets add a touch of elegance and sophistication to the overall design of the elevator. The embossed patterns create a visually appealing surface that can enhance the aesthetic appeal of the interior space. This is especially important in commercial buildings and high-end residential complexes where a luxurious ambiance is desired. Secondly, embossed stainless steel sheets are highly durable and resistant to wear and tear. Elevator interiors are subject to constant use and can be prone to scratches, dents, and other damages. The embossed pattern on the stainless steel surface helps to hide minor imperfections, ensuring that the interior maintains its pristine appearance for a longer period of time. Additionally, stainless steel is known for its corrosion resistance, making it a suitable choice for environments with high humidity levels, such as elevator shafts. Furthermore, embossed stainless steel sheets are easy to clean and maintain. Elevator interiors are often exposed to dirt, fingerprints, and other stains. The smooth surface of the embossed stainless steel makes it easy to wipe away these marks, ensuring that the interior always looks clean and well-maintained. This is particularly important in public spaces where cleanliness is essential for creating a positive impression on users. Additionally, embossed stainless steel sheets offer a high level of customization. They can be manufactured in various patterns, textures, and finishes, allowing for endless design possibilities. This enables architects and designers to create unique and personalized elevator interiors that reflect the desired theme or branding of a building. The versatility of embossed stainless steel also makes it easy to match with other interior design elements, such as flooring, lighting fixtures, and wall coverings. In conclusion, the benefits of using embossed stainless steel sheets in elevator interiors include enhanced visual appeal, durability, ease of maintenance, and customization options. These qualities make embossed stainless steel an ideal material for elevators in various settings, from commercial buildings to residential complexes, adding value and elegance to the overall design.

- Q: Are stainless steel sheets suitable for electrical applications?

- Yes, stainless steel sheets are suitable for electrical applications. Stainless steel is a highly conductive material and is resistant to corrosion, making it an ideal choice for various electrical components and equipment. Additionally, stainless steel sheets provide durability and excellent mechanical properties, ensuring long-lasting performance in electrical applications.

- Q: What is the difference between cold rolled and hot rolled stainless steel sheets?

- The main difference between cold rolled and hot rolled stainless steel sheets lies in the manufacturing process. Cold rolled stainless steel sheets are produced by rolling the steel at a lower temperature, which results in a smoother and more polished finish. Hot rolled stainless steel sheets, on the other hand, are produced by rolling the steel at a higher temperature, which makes them less smooth and less polished. Additionally, hot rolled sheets tend to have a thicker gauge compared to cold rolled sheets.

- Q: Can stainless steel sheets be used for aerospace fasteners?

- Yes, stainless steel sheets can be used for aerospace fasteners. Stainless steel is a commonly used material in aerospace applications due to its high strength, corrosion resistance, and ability to withstand extreme temperatures. It is often used for fasteners such as screws, bolts, and nuts in aerospace engineering.

- Q: What's the difference between stainless steel hot rolling and cold rolling?

- Cold rolling: it is rolled and rolled on the basis of hot rolled stainless steel plate and coil. Generally speaking, it is the process of hot rolling, pickling and cold rolling. Although the rolling process also causes the steel plate to heat up during the process, it is called cold rolling. Because of the cold rolling of continuous hot rolling, the mechanical properties are poor and the hardness is too high. It must be annealed to restore its mechanical properties. Rolled rolls are generally used to make products without bending or stretching.

- Q: What's the difference between galvanized steel and stainless steel?

- Galvanized steel sheet is to prevent the corrosion of steel plate surface, and prolong its service life, the surface of the steel plate is coated with a layer of metal zinc, this kind of zinc coated steel sheet is called galvanized sheet.

Send your message to us

CorrugatedStainless Steel Sheet with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords