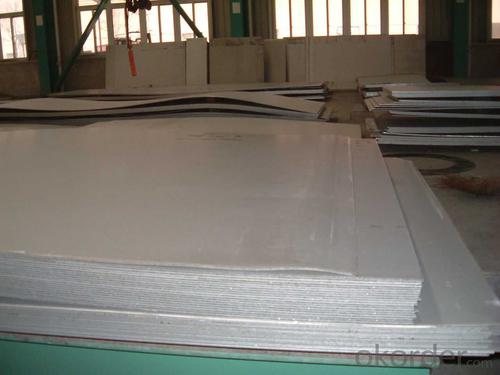

Stainless Steel Sheet and plate with surface treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 250 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: The difference between 304J1 stainless steel plate and 304 stainless steel plate

- 1. characteristics and uses: steel grades, characteristics, uses304, excellent formability, deep drawing applications - tableware, vacuum cups, sinks, pots and other deep drawing purposes

- Q: Can stainless steel sheets be used for fire-rated applications?

- Yes, stainless steel sheets can be used for fire-rated applications. Stainless steel is known for its high melting point and excellent heat resistance properties. It retains its strength and integrity even at high temperatures, making it a suitable material for fire-rated applications. Stainless steel sheets are often used in fire-rated doors, walls, and ceilings, providing a durable and reliable barrier against fire. Additionally, stainless steel's corrosion resistance properties make it a long-lasting option, ensuring its effectiveness in fire-rated applications over time.

- Q: How do I select the appropriate thickness for stainless steel sheets?

- There are several factors to take into account when choosing the right thickness for stainless steel sheets. The first and foremost consideration is the specific purpose or application for which the sheets will be used. For decorative purposes, such as interior design or architectural projects, a thinner gauge may be more suitable. Thinner gauges, typically ranging from 26 to 30 gauge, offer more flexibility and are easier to shape. This makes them perfect for intricate designs or curved surfaces. On the other hand, if you need stainless steel sheets for structural or industrial purposes, a thicker gauge would be better. Thicker gauges, usually ranging from 18 to 20 gauge, provide increased strength and durability. This makes them ideal for heavy-duty applications like construction, automotive, or manufacturing. It is also important to consider the intended use of the sheets. If they will be exposed to harsh environments, heavy loads, or high levels of wear and tear, it is advisable to choose a thicker gauge. This will ensure that the sheets can withstand these conditions without compromising their integrity. Lastly, budget constraints may also influence the choice of thickness. Thicker gauges tend to be more expensive due to the larger amount of material required. Therefore, it is crucial to find a balance between the desired strength and the available budget. In conclusion, when selecting the appropriate thickness for stainless steel sheets, it is important to consider the intended application, the required strength and durability, and any budget limitations. By taking these factors into consideration, you can choose the most suitable thickness that meets your specific needs.

- Q: What do stainless steel 304 industrial surfaces refer to?

- The industrial surface is the ordinary pickling surface, which is treated by the last pickling process. Is the kind of white surface that you see at ordinary times. The bright surface of life is the surface of which is further polished or annealed.

- Q: Are stainless steel sheets suitable for corrosive environments?

- Yes, stainless steel sheets are highly suitable for corrosive environments. This is because stainless steel contains alloying elements such as chromium, which forms a protective layer on the surface, preventing corrosion and rusting. Additionally, stainless steel has excellent resistance to a wide range of corrosive substances, making it ideal for various industries and applications where exposure to corrosive environments is common.

- Q: How do you remove adhesive residue from stainless steel sheets?

- To effectively eliminate adhesive residue from stainless steel sheets, the following steps can be followed: 1. Commence by delicately scraping off as much of the residue as possible using a plastic scraper or your fingernail. Exercise caution to avoid scratching the stainless steel surface. 2. Subsequently, moisten a soft cloth with warm water and a mild detergent or dish soap. Employ gentle circular motions to scrub the adhesive residue. Refrain from using abrasive cleaners or scrub brushes as they have the potential to harm the stainless steel finish. 3. If the adhesive residue persists, consider utilizing a non-abrasive cleaner specifically designed for stainless steel. Apply a small quantity of the cleaner to a soft cloth and gently rub the residue until it detaches. 4. In the case of tenacious adhesive residue, a paste can be concocted by combining baking soda and water. Apply the paste to the affected area and allow it to sit for a few minutes. Subsequently, utilize a soft cloth to gently scrub the residue in circular motions. 5. Thoroughly rinse the stainless steel sheet with warm water to eliminate any remaining residue or cleaner. 6. Finally, employ a clean, soft cloth to dry the surface, thereby preventing water spots and streaks. It is important to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet prior to applying it to the entire surface. This precautionary measure ensures that no damage or discoloration occurs.

- Q: Are stainless steel sheets suitable for roofing?

- Yes, stainless steel sheets are suitable for roofing. They have excellent durability, corrosion resistance, and can withstand extreme weather conditions. Additionally, their sleek appearance adds aesthetic value to any building.

- Q: Can stainless steel sheets be used in architectural designs?

- Certainly, architectural designs can definitely incorporate stainless steel sheets. Stainless steel is a highly adaptable material that offers numerous advantages for architectural purposes. It is renowned for its durability, resistance to corrosion, and attractive appearance, which has made it a favored option among architects and designers. Stainless steel sheets can be utilized in various architectural elements, including cladding, roofing, facades, and decorative features. The sleek and contemporary look of the material adds a touch of sophistication to any design, whether it be a residential building, commercial structure, or public space. One of the primary benefits of stainless steel sheets is their ability to resist corrosion, making them suitable for both interior and exterior use. They can withstand severe weather conditions, UV radiation, and pollutants, ensuring a long-lasting and low-maintenance solution for architectural projects. Furthermore, stainless steel sheets are available in a variety of finishes, such as brushed, polished, and patterned, allowing architects to create distinctive and visually appealing designs. The material can be easily shaped, welded, and fabricated into various forms, enabling architects to achieve their desired architectural vision. Stainless steel sheets also provide excellent fire resistance, making them ideal for applications where safety is a priority. They are non-combustible and have a high melting point, offering additional protection in the event of a fire. Moreover, stainless steel is an environmentally friendly choice. It is 100% recyclable, with a high recycling rate, reducing the demand for new raw materials and helping to minimize waste. In summary, stainless steel sheets are a versatile and durable material that can be effectively utilized in architectural designs. Their resistance to corrosion, aesthetic appeal, fire resistance, and sustainability make them a popular choice among architects and designers for a wide range of applications.

- Q: What kind of screws do you choose for stainless steel plates?

- If it's a fixed plate, ordinary ones will doOf course, stainless steel screws are the best

- Q: Can stainless steel sheets be used for food storage containers?

- Yes, stainless steel sheets can be used for food storage containers. Stainless steel is a popular choice for food storage containers due to its durability, non-reactive nature, and resistance to corrosion. It does not impart any taste or odor to the stored food, making it safe for long-term storage. Stainless steel is also easy to clean and maintain, making it a hygienic option for food storage. Additionally, stainless steel containers are often preferred for their eco-friendly properties, as they are reusable and can help reduce the use of single-use plastic containers. Overall, stainless steel sheets are a suitable and reliable choice for food storage containers.

Send your message to us

Stainless Steel Sheet and plate with surface treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 250 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords