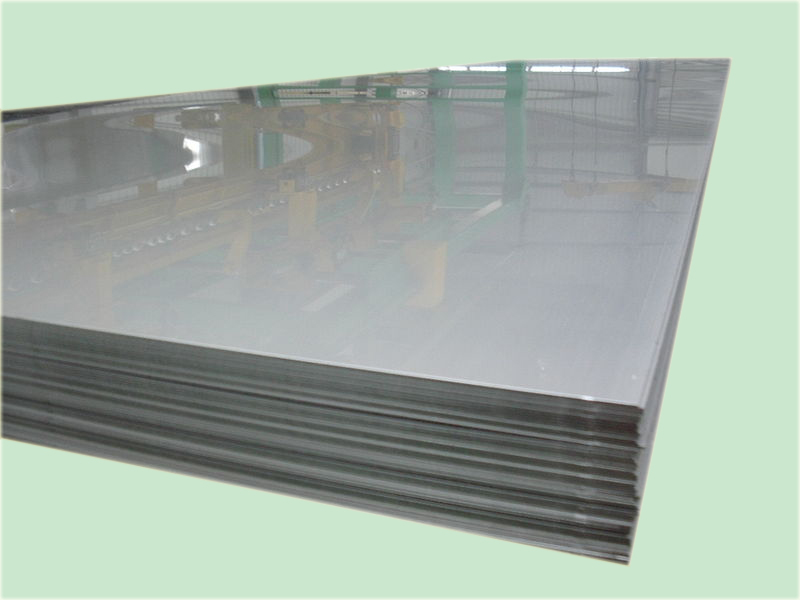

AISI316L Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 3000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

316L Stainless Steel Sheet

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

Max0.03 |

max1.00 |

max2.00 |

max0.045 |

max0.03 |

10.00-14.00 |

16.00-18.00 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥175 |

≥480 |

≥40 |

≤200 |

≤90 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q: What is the price range of stainless steel strips?

- The price range of stainless steel strips can vary depending on factors such as size, thickness, grade, and quantity. Generally, stainless steel strips can range from a few dollars per square foot to several hundred dollars per square foot. It is recommended to check with suppliers or manufacturers for specific pricing details.

- Q: What is the corrosion resistance of stainless steel strips in different environments?

- Stainless steel strips have excellent corrosion resistance in various environments, making them highly versatile and durable. In general, stainless steel is resistant to rust and corrosion caused by moisture, chemicals, and atmospheric conditions. However, the level of corrosion resistance can vary depending on the specific type and grade of stainless steel, as well as the specific environment it is exposed to. For example, stainless steel with a higher chromium content tends to have better corrosion resistance in acidic environments, while those with higher nickel content perform well in salty or marine environments. Overall, stainless steel strips offer reliable corrosion resistance in a wide range of environments, making them suitable for numerous applications.

- Q: How are stainless steel strips measured?

- Stainless steel strips are typically measured using two primary dimensions: thickness and width. The thickness is measured in millimeters or inches, while the width is measured in millimeters. These measurements provide the necessary information for determining the size and specifications of stainless steel strips.

- Q: What is the electrical resistivity of stainless steel strips?

- The electrical resistivity of stainless steel strips can vary depending on the specific grade and composition of the stainless steel. However, typically, stainless steel strips have a relatively high electrical resistivity compared to other metals, ranging from 70 to 80 micro-ohm centimeters.

- Q: What are the factors affecting the formability of 111 stainless steel strips?

- There are several factors that can affect the formability of 111 stainless steel strips. 1. Alloy Composition: The chemical composition of the stainless steel strip, including the percentage of different elements such as chromium, nickel, and molybdenum, can greatly impact its formability. Higher amounts of certain elements can improve the strip's ability to be formed into desired shapes. 2. Grain Size: The size of the grains within the stainless steel strip can also affect its formability. Smaller grain sizes generally result in improved formability, as they offer a more uniform and consistent material structure. 3. Mechanical Properties: The mechanical properties of the stainless steel strip, such as its strength, ductility, and hardness, can significantly influence its formability. Strips with higher ductility are generally easier to form without cracking or breaking. 4. Surface Condition: The surface condition of the stainless steel strip, including its roughness and cleanliness, can impact its formability. A smooth and clean surface can reduce friction and improve the strip's ability to be shaped without defects. 5. Temperature: The temperature at which the stainless steel strip is being formed can also affect its formability. Higher temperatures can help to soften the material, making it more malleable and easier to shape. 6. Lubrication: The use of lubricants during the forming process can reduce friction and improve the formability of the stainless steel strip. Lubricants help to reduce the likelihood of galling, scratching, or sticking during forming operations. 7. Forming Method: The method used to form the stainless steel strip, such as bending, stretching, or deep drawing, can also impact its formability. Different forming methods impose different levels of stress and strain on the material, which can affect its ability to be shaped without failure. Overall, these factors, including alloy composition, grain size, mechanical properties, surface condition, temperature, lubrication, and forming method, all play a significant role in determining the formability of 111 stainless steel strips.

- Q: What are the maximum temperatures stainless steel strips can withstand?

- The maximum temperatures that stainless steel strips can withstand depend on the specific grade of stainless steel being used. Generally, stainless steel is known for its high temperature resistance, making it suitable for a wide range of applications. The most commonly used grades of stainless steel, such as 304 and 316, can typically withstand temperatures up to around 1500°F (815°C) without experiencing significant deformation or loss of mechanical properties. However, there are specialized grades of stainless steel, such as 310 and 330, that have even higher temperature resistance and can withstand temperatures up to approximately 2100°F (1150°C). It is important to consider the specific grade and intended application when determining the maximum temperature that stainless steel strips can withstand.

- Q: Can stainless steel strips be used in marine applications?

- Yes, stainless steel strips can be used in marine applications. Stainless steel is known for its corrosion resistance, making it an ideal material for marine environments where it is constantly exposed to saltwater and moisture. Stainless steel strips are often used in marine applications such as boat hardware, marine fittings, and structural components. They are designed to withstand the harsh conditions of the sea, including high levels of salt, humidity, and UV exposure. Additionally, stainless steel strips offer excellent strength and durability, ensuring they can withstand the demanding conditions of marine environments over an extended period of time.

- Q: Are 111 stainless steel strips suitable for power generation equipment?

- Power generation equipment can indeed benefit from the use of 111 stainless steel strips. This particular type of stainless steel, known as ferritic stainless steel, contains 11% chromium. This composition grants it the ability to withstand corrosion and oxidation at high temperatures, making it a fitting choice for power generation equipment. These machines often operate under elevated temperatures and are exposed to corrosive environments, further highlighting the suitability of 111 stainless steel. Moreover, 111 stainless steel boasts commendable mechanical properties, including high strength and hardness. These attributes are crucial in enabling the material to endure the stresses and strains encountered in power generation equipment. However, it is important to note that the appropriateness of utilizing 111 stainless steel strips ultimately hinges on the specific requirements and conditions of the equipment. Consulting experts or engineers is therefore strongly advised to ensure the selection of the most suitable material.

- Q: Are stainless steel strips available in different finishes?

- Yes, stainless steel strips are available in various finishes including matte, brushed, mirror, and patterned finishes.

- Q: Can 111 stainless steel strips be used in the oil and gas industry?

- Indeed, the oil and gas industry can utilize 111 stainless steel strips to great effect. This particular grade of stainless steel, 111 stainless steel, is widely employed due to its commendable resistance against corrosion, remarkable strength, and exceptional malleability. Such attributes render it suitable for a diverse range of applications within the oil and gas sector, encompassing piping, storage tanks, heat exchangers, and various equipment. Moreover, 111 stainless steel strips are capable of withstanding harsh environmental conditions, including exposure to corrosive substances, high temperatures, and pressure, thereby solidifying their status as a dependable choice for the oil and gas industry.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

AISI316L Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 3000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords