Stainless steel sheet,440C (9Cr18MoV) in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Square

Surface Treatment:

Polished

Steel Grade:

300 Series

Certification:

SGS

Thickness:

3

Width:

1500

Length:

3000

Net Weight:

25

Product Description

![]()

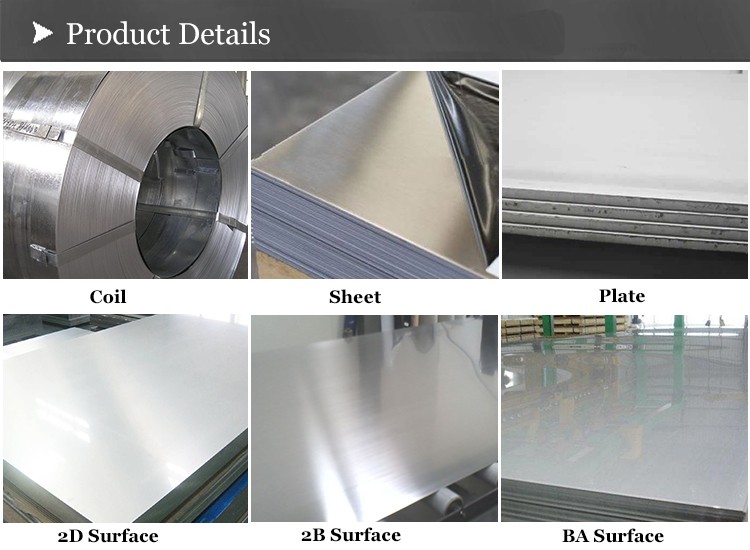

| Name | Stainless steel sheet,440C (9Cr18MoV),N695 Hardness:55-60Hrc |

| Standard | ASTM A276, JIS G4303, AS 2837 |

| Material Grade | W.Nr 1.4125 , X105CrMo17, 440C , 9Cr18MoV, SAE 51440C , UNS S44004 |

| Technique | Cold Rolled |

| Thickness | 0.1mm-200mm or as your requirement |

| Width | 1000mm-3000mm or as your requirement |

| Length | As your requirement |

| Surface Treatment | No.1,2B,2D,BA, or as your needs |

| Packing | 1. Export sea worthy package + water proof paper + wooden pallet |

| 2. Max Loading 26.5mt for each 20Gp container | |

| 3.Safe loading and fixing Professional Teams | |

| 4. Professional shipping line | |

| Delivery | According to the order quantity or upon negotiation |

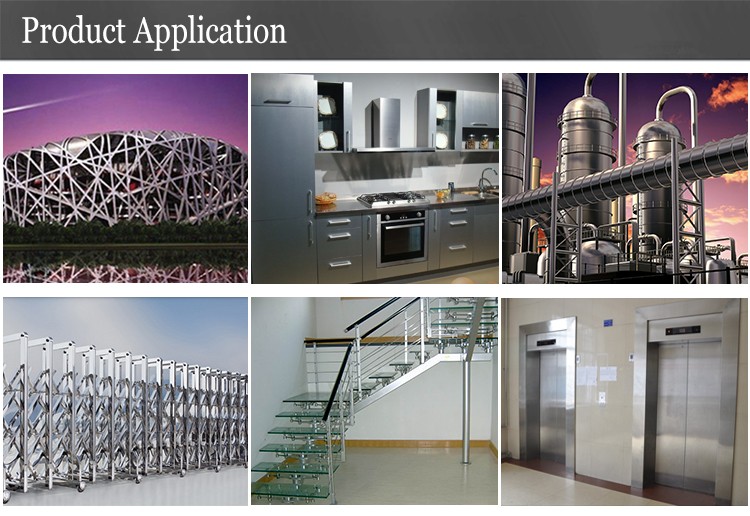

| Application | Stainless Steel Coils are widely used in below fields: |

| 1: Construction field, shipping building industry | |

| 2: Pipe weldeding | |

| 3: Food and Mechanical Industries | |

| Quality control | Mill Test Certificate is supplied with shipment |

| Accept any third party inspection |

Qulity Control

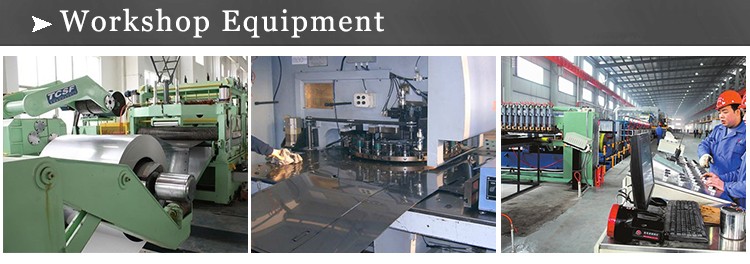

Third party inspection that is preferred by new customers are proved to be convincing. Through years' of operation, M/S Chengdu Derbo has established stable contact with world famous third party inspection authorities like BV, SGS, INTERTEK, etc, and more than 5000M.Tons of steel pipes/tubes from Chengdu Derbo have been inspected by them.

Packaging & Shipping

- Q: What are the factors to consider when selecting the right grade of stainless steel sheet?

- When selecting the right grade of stainless steel sheet, there are several important factors to consider. These include the intended application and environment, desired corrosion resistance, strength requirements, temperature resistance, and budget constraints. Additionally, factors like fabrication ease, availability, and aesthetic preferences should also be taken into account. Ultimately, it is crucial to carefully evaluate these factors in order to choose the most suitable grade of stainless steel sheet for your specific needs.

- Q: Can stainless steel sheets be used for medical equipment?

- Indeed, medical equipment can utilize stainless steel sheets. The medical industry extensively employs stainless steel due to its remarkable resistance to corrosion, its durability, and its ease of cleaning. Surgical instruments, implants, medical devices, and equipment like sterilization trays, hospital beds, and operating room tables are commonly manufactured using stainless steel. As it does not react with bodily tissues or fluids, stainless steel is a secure and sanitary option for medical purposes. Moreover, it can endure numerous sterilization procedures without compromising its qualities, thus rendering it perfectly suited for hospitals and healthcare facilities.

- Q: Are stainless steel sheets suitable for welding or fabrication?

- Yes, stainless steel sheets are suitable for welding and fabrication. Stainless steel has excellent weldability, which means it can be easily fused together using various welding techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. It also has good formability, allowing it to be easily shaped and fabricated into different structures or components. Additionally, stainless steel sheets offer high strength and corrosion resistance, making them a popular choice in industries such as construction, automotive, and manufacturing. Overall, stainless steel sheets are a versatile and reliable material for welding and fabrication applications.

- Q: Can stainless steel sheets be used for swimming pool installations?

- Certainly! Stainless steel sheets are a great option for swimming pool installations. With their exceptional durability and resistance to corrosion, stainless steel is well-suited for use in pools. It can withstand rust, stains, and the various chemicals usually present in pool water, making it a dependable choice for long-term usage. In fact, stainless steel sheets are frequently employed for constructing pool walls, floors, and other crucial components due to their ability to endure the challenging conditions typical of pool environments. Moreover, stainless steel possesses a sleek and contemporary look that contributes to the pool's overall aesthetic appeal.

- Q: Can stainless steel sheets be customized in terms of size and shape?

- Yes, stainless steel sheets can be customized in terms of size and shape. Stainless steel is a highly versatile material that can be easily manipulated and transformed to meet specific requirements. Whether it is a large sheet or a small one, stainless steel can be cut, shaped, and resized to fit the desired dimensions. This customization process can be achieved through various techniques such as cutting, bending, welding, and forming. Additionally, stainless steel sheets can also be perforated or embossed to add further customization and enhance their aesthetic appeal. Overall, stainless steel sheets offer great flexibility in terms of size and shape customization, making them suitable for a wide range of applications in industries such as construction, automotive, aerospace, and more.

- Q: Can stainless steel sheets be used for solar panel frames?

- Yes, stainless steel sheets can be used for solar panel frames. Stainless steel is a popular choice for solar panel frames due to its high strength, durability, and corrosion resistance properties. It can withstand various weather conditions, including extreme heat, humidity, and exposure to sunlight. Additionally, stainless steel is non-magnetic and non-combustible, making it a safe choice for solar panel installations. Its high strength-to-weight ratio also allows for lighter frame designs, reducing the overall weight of the solar panels and making them easier to install. Overall, stainless steel sheets are a reliable and long-lasting option for constructing solar panel frames.

- Q: Are stainless steel sheets suitable for railway station platforms?

- Yes, stainless steel sheets are suitable for railway station platforms. Stainless steel is a highly durable material that can withstand heavy foot traffic and extreme weather conditions, making it an ideal choice for platforms in railway stations. It is resistant to corrosion, which is crucial in areas exposed to moisture, such as platforms where rain, snow, or spilled liquids may occur. Stainless steel sheets are also easy to clean and maintain, ensuring a hygienic and safe environment for passengers. Additionally, stainless steel has a sleek and modern appearance, adding to the aesthetic appeal of the railway station. Overall, stainless steel sheets provide the necessary strength, durability, and aesthetic qualities required for railway station platforms.

- Q: Are stainless steel sheets resistant to caustic soda?

- Yes, stainless steel sheets are generally resistant to caustic soda. Caustic soda, also known as sodium hydroxide, is a highly corrosive substance, but stainless steel is known for its excellent corrosion resistance. Stainless steel contains chromium, which forms a protective oxide layer on the surface of the metal, preventing it from reacting with caustic soda. However, it is important to note that the exact resistance of stainless steel to caustic soda may vary depending on the grade or type of stainless steel. Therefore, it is always recommended to consult the specific material specifications or consult with a qualified professional to ensure the appropriate choice of stainless steel for specific applications involving caustic soda.

- Q: What are the common methods of cutting stainless steel sheets?

- Cutting stainless steel sheets can be done using various methods, each with its own advantages and limitations. Let's take a look at a few commonly employed techniques: 1. Shearing: When using shearing, a machine with two blades is utilized to effortlessly slice through the stainless steel sheet. This technique is ideal for thinner sheets and delivers clean, straight cuts. However, there is a possibility of a slight burr on the cut edge. 2. Plasma cutting: Plasma cutting is a versatile approach that harnesses a high-temperature plasma arc to melt and remove the metal. This method is effective for cutting stainless steel sheets of different thicknesses and shapes. It offers speedy and precise cuts, accommodating both straight and curved lines. 3. Laser cutting: Laser cutting relies on a focused laser beam to effectively slice through stainless steel sheets. It is known for its high level of accuracy, generating smooth and precise cuts with minimal distortion. Laser cutting is suitable for thin and thick sheets but may be slower than other methods when dealing with thicker materials. 4. Waterjet cutting: Waterjet cutting employs a high-pressure stream of water mixed with abrasive particles to carve through stainless steel. This technique is renowned for its precision and ability to handle varying thicknesses and shapes. Waterjet cutting produces clean edges and avoids heat-affected zones. However, it may be slower and more costly compared to other methods. 5. Sawing: Sawing is a traditional method that employs a saw blade to cut through stainless steel sheets. It is most suitable for thicker sheets and can handle both straight and curved cuts. Sawing yields relatively clean cuts, although it may result in more material waste compared to other techniques. These are just a few examples of the common methods employed to cut stainless steel sheets. The choice of method depends on factors such as sheet thickness, desired cut quality, shape complexity, and budget. It is crucial to consider the specific requirements of the project and seek professional advice to determine the most suitable cutting method.

- Q: Can stainless steel sheets be used for elevator frames?

- Yes, stainless steel sheets can be used for elevator frames. Stainless steel is known for its durability, strength, and resistance to corrosion, making it an ideal material for various applications, including elevator frames. The use of stainless steel sheets for elevator frames ensures a long-lasting and aesthetically pleasing structure that can withstand the wear and tear of everyday use. Additionally, stainless steel's sleek and modern appearance can enhance the overall design of the elevator, providing a sophisticated and stylish look.

Send your message to us

Stainless steel sheet,440C (9Cr18MoV) in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords