Steel sheets for sale wholesale china import

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 57483 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

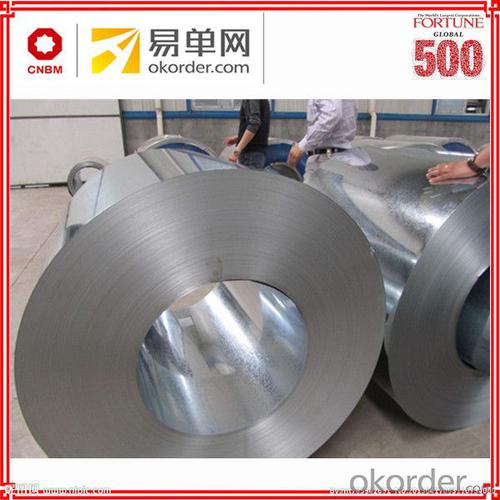

Cold rolled sheet products have been available for many, many years, and have been successfully used for a multitude of

applications. Today's cold rolled sheet products are much improved over those used in the past. They offer better control of

thickness, shape, width, surface finish, and other special quality features that compliment the emerging need for highly

engineered end use applications.

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep

drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition

and their mechanical properties, which guarantees processing consistency.

.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

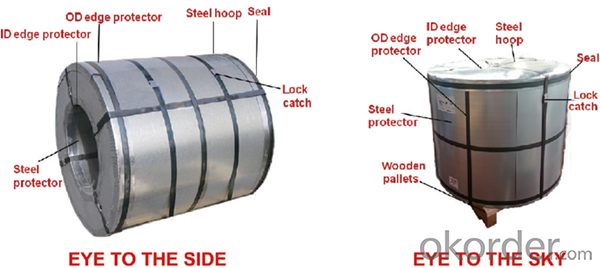

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will

provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing

as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: Are the steel sheets suitable for architectural cladding?

- Steel sheets are indeed appropriate for architectural cladding. Steel, being a sturdy and long-lasting substance, offers outstanding defense against weather conditions and external influences. It is easily malleable and can be crafted into diverse shapes, making it extremely adaptable for architectural purposes. Moreover, steel cladding provides a contemporary and polished appearance, permitting the creation of visually captivating building exteriors. Additionally, steel sheets can be coated or painted to augment their ability to resist corrosion and to further personalize their look. All in all, due to their strength, durability, versatility, and aesthetic allure, steel sheets are widely favored for architectural cladding.

- Q: Can steel sheets be used in architectural or decorative applications?

- Yes, steel sheets can be used in architectural or decorative applications. Steel sheets offer durability, versatility, and a sleek aesthetic that make them suitable for various architectural and decorative purposes such as cladding, roofing, wall panels, and interior design elements.

- Q: Can steel sheets be used for noise reduction purposes?

- Yes, steel sheets can be used for noise reduction purposes. Steel has high density and stiffness, which helps to block and absorb sound waves, reducing noise transmission. Steel sheets are commonly used in construction, industrial settings, and automotive applications to create barriers or enclosures that minimize noise levels.

- Q: What are the color options for steel sheets?

- The color options for steel sheets can vary, but some common choices include silver, black, white, gray, and various shades of metallic colors such as bronze or copper. Additionally, steel sheets can also be painted or coated with a variety of colors to suit specific preferences or design requirements.

- Q: What are the different finishes available for steel sheets?

- Some of the different finishes available for steel sheets include hot rolled, cold rolled, galvanized, and coated finishes.

- Q: Can the steel sheets be used for decorative purposes?

- Certainly, decorative purposes can be fulfilled by steel sheets. Customization and shaping of steel sheets into an array of designs, patterns, and sizes enable their suitability for diverse decorative applications. They are ideal for crafting distinctive and contemporary architectural elements like ornamental facades, decorative wall panels, or intricate metal screens. Moreover, steel sheets find utility in decorative furniture, art installations, and sculptures. Their popularity stems from their versatility, durability, and sleek appearance, which effortlessly infuse spaces with elegance and sophistication, both indoors and outdoors.

- Q: Can steel sheets be used in the medical industry?

- Yes, steel sheets can be used in the medical industry. They are often used in the manufacturing of medical equipment, surgical instruments, and medical furniture due to their durability, corrosion resistance, and ease of sterilization.

- Q: Are steel sheets suitable for food storage applications?

- Food storage applications can benefit greatly from the use of steel sheets. This material offers exceptional durability and versatility, with its resistance to corrosion making it an ideal option for storing food. Steel sheets create a hygienic and secure environment for food, as they are non-porous and do not retain odors or flavors. Moreover, they provide reliable protection against contaminants and pests, ensuring the maintained quality and freshness of the stored food. Furthermore, steel sheets are effortlessly cleaned and maintained, making them the perfect choice for food storage facilities, restaurants, and any other setting where food safety is of utmost importance.

- Q: Can steel sheets be used for construction formwork or molds?

- Certainly, construction formwork or molds can utilize steel sheets, although their usage may not be as prevalent as materials like plywood or timber. Robust and enduring, steel sheets offer a sleek and uniform surface for concrete casting. They prove especially fitting for expansive construction ventures demanding formwork capable of withstanding immense pressures and loads. Additionally, steel sheets can be tailor-made and manufactured to meet precise project specifications, affording versatility in terms of shape, size, and arrangement. Nevertheless, the cost, weight, and accessibility of steel sheets should be weighed against alternative formwork materials prior to reaching a verdict.

- Q: Are steel sheets suitable for chemical storage tanks?

- Yes, steel sheets are suitable for chemical storage tanks. Steel is a highly durable and strong material that can withstand the corrosive nature of many chemicals. Additionally, steel sheets can be coated with protective layers or linings to further enhance their resistance to chemicals, making them a reliable choice for chemical storage tanks.

Send your message to us

Steel sheets for sale wholesale china import

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 57483 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords