Hot Rolled Stainless Steel Grade 304L NO.1 Finish From China Supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Features of Stainless Steel Coils

(1) Good ductility

(2) Good corrosion resistance

(3) Excellent abrasion resistance and fatigue strength

(4) Good weldability

(5) Oxidation resistant performance

(6) Excellent in high temperature

Application of Stainless Steel Coils

(1) Boiler heat exchanger,

(2) Chemical industries,

(3) Hardware fields,

(4) Construction material,

(5) Kitchen utensils,

(6) Building construction,

(7) Medical equipment,

(8) chemical tank,

(9) pipe etc

Payment&Delivery

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

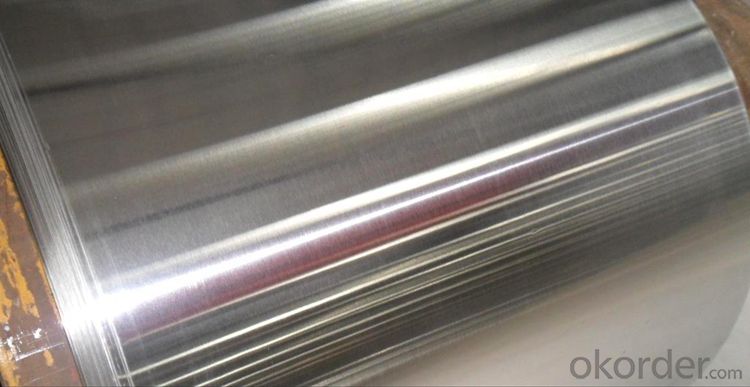

Detail picture of Products:

Export Markets

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: What is the difference between the stainless steel plate and the second board?

- The above points, is to distinguish between the material and the main difference between calendering, the most commonly used is that the card thickness and surface conditions can basically be distinguished

- Q: Can stainless steel sheets be used for automotive applications?

- Certainly, automotive applications can make use of stainless steel sheets. Renowned for its versatility and durability, stainless steel proves to be an exceptional material that exhibits remarkable resistance against corrosion, heat, and impact. These exceptional qualities render it highly suitable for automotive applications wherein durability and resistance against harsh environments are crucial aspects. Stainless steel sheets find utility across various domains of the automotive industry, encompassing body panels, exhaust systems, fuel tanks, and even interior components. Moreover, stainless steel can be effortlessly shaped, welded, and manipulated to meet precise design prerequisites, thus solidifying its status as a favored option within the automotive industry.

- Q: Can stainless steel sheets be used for mezzanine flooring?

- Yes, stainless steel sheets can be used for mezzanine flooring. Stainless steel is a durable and corrosion-resistant material, making it suitable for high traffic areas like mezzanine floors. It offers strength and stability, making it a popular choice for industrial and commercial applications.

- Q: Are stainless steel sheets suitable for automotive exhaust systems?

- Yes, stainless steel sheets are suitable for automotive exhaust systems. Stainless steel is a preferred material for exhaust systems due to its high resistance to corrosion, heat, and vibration. It can withstand the high temperatures and harsh conditions that exhaust systems are exposed to, making it a durable and long-lasting choice. Additionally, stainless steel has excellent thermal conductivity, which helps in dissipating heat efficiently. It also offers good formability, allowing manufacturers to design and shape the exhaust components as needed. Overall, stainless steel sheets are a reliable and popular choice for automotive exhaust systems.

- Q: Can stainless steel sheets be used for elevator mirror panels?

- Yes, stainless steel sheets can be used for elevator mirror panels. Stainless steel is a durable and corrosion-resistant material that is commonly used in the construction of elevator interiors. Additionally, stainless steel can be polished to a high shine, making it suitable for mirror panels in elevators.

- Q: Can stainless steel sheets be painted or coated?

- Yes, stainless steel sheets can be painted or coated. However, it is important to properly prepare the surface by cleaning and applying a suitable primer before painting or coating to ensure adhesion and durability of the finish.

- Q: Are stainless steel sheets suitable for cryogenic applications?

- Yes, stainless steel sheets are suitable for cryogenic applications due to their excellent mechanical properties, low thermal conductivity, and resistance to temperature extremes. Stainless steel can maintain its strength and integrity even at extremely low temperatures, making it an ideal material for cryogenic storage tanks, pipelines, and equipment.

- Q: What are the different types of edge finishes available for stainless steel sheets?

- There are several types of edge finishes available for stainless steel sheets, including the straight edge, beveled edge, rounded edge, and hemmed edge.

- Q: Are stainless steel sheets suitable for laboratory equipment or instruments?

- Yes, stainless steel sheets are highly suitable for laboratory equipment and instruments. Stainless steel is known for its excellent corrosion resistance, which is crucial in laboratory environments where equipment comes into contact with various chemicals and substances. It is also highly resistant to heat, making it suitable for use with high-temperature processes or sterilization procedures. Additionally, stainless steel is easy to clean and maintain, which is essential for maintaining a sterile and hygienic laboratory environment. The durability and strength of stainless steel make it ideal for withstanding heavy usage and ensuring long-lasting performance. Overall, stainless steel sheets are a reliable and popular choice for laboratory equipment and instruments due to their corrosion resistance, heat resistance, cleanliness, and durability.

- Q: Can stainless steel sheets be used for oil and gas pipelines?

- Indeed, oil and gas pipelines can utilize stainless steel sheets. The oil and gas industry frequently relies on stainless steel because it possesses remarkable resistance against corrosion. It can endure the demanding circumstances involved in the transportation and storage of oil and gas, encompassing high pressure, high temperature, and corrosive surroundings. When constructing pipeline components like pipes, fittings, and flanges, stainless steel sheets are commonly employed. They provide longevity, robustness, and the ability to resist corrosion, thereby aiding in leak prevention and the preservation of pipeline integrity.

Send your message to us

Hot Rolled Stainless Steel Grade 304L NO.1 Finish From China Supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords