Astm 316 321 Stainless Steel Sheets in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Hot Rolled

Shape:

Square

Surface Treatment:

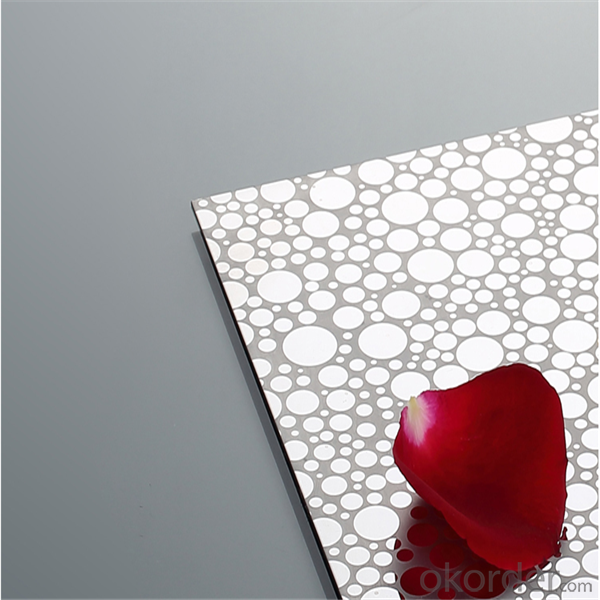

Polished

Steel Grade:

300 Series

Certification:

SGS

Thickness:

4

Width:

1500

Length:

6000

Net Weight:

32

Astm 316 321 Stainless Steel Sheets in China

Features:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

| ITEM | DESCRIPTION |

| Product | Stainless Steel Sheet |

| Standard | JIS, AISI, ASTM, GB, DIN, EN, etc. |

| Material | 201, 202, 304, 304L, 316, 310S, 316L, etc. |

| Thickness | 0.1mm-150mm |

| Width | 500mm-3000mm |

| Length | 500mm-6000mm |

| Certificate | BV, ISO, SGS, etc. |

| Application | Widely |

| MOQ | 1 Ton |

| Brand | TISCO, LISCO, POSCO. |

| Type | Plate |

| Port | Shanghai,China |

| Payment | L/C,T/T |

| Place of origin | Jiangsu, China |

| Product Ability | 3000 tons per month. |

| Package | Standard seaworthy export packing or according to the customers' request. |

| Delivery Time | It is based on the order, normally within 10 days after receiving your advance payment. |

| Surface and application | ||

| SURFACE | DEFINITION | APPLICATION |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| BA (No.6) | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building Construction. |

| Mirror (No.8) | Shinning like a mirror. | Building construction. |

| The Chemical Composition | |||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | ||

| 201 | 1Cr17Mn6Ni5N | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 |

| 202 | 1Cr18Mn8Ni5N | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 |

| 301 | 1Cr17Ni7 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.065 | ≤0.030 | - | ≤1.00 | - | - |

| 304 | 1Cr18Ni9 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - |

| 304L | 00Cr19Ni10 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - |

| 309S | 0Cr23Ni13 | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - |

| 310S | 0Cr25Ni20 | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - |

| 316 | 0Cr17Ni12Mo2 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - |

| 1Cr18Ni12Mo2Ti6) | ≤0.12 | 16.00-19.00 | 11.00-14.00 | ≤2.00 | ≤0.035 | ≤0.030 | 1.80-2.50 | ≤1.00 | - | - | |

| 0Cr18Ni12Mo2Ti | ≤0.08 | 16.00-19.00 | 11.00-14.00 | ≤2.00 | ≤0.035 | ≤0.030 | 1.80-2.50 | ≤1.00 | - | - | |

| 316L | 00Cr17Ni14Mo2 | ≤0.030 | 16.00-18.00 | 12.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - |

| 317 | 0Cr19Ni13Mo3 | ≤0.12 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | - |

| 317L | 00Cr19Ni13Mo3 | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | - |

| 321 | 1Cr18Ni9Ti6) | ≤0.12 | 17.00-19.00 | 8.00-11.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | ≤1.25 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | |

| 430F | Y1Cr17 | ≤0.12 | 16.00-18.00 | ≤1.00 | ≤0.035 | ≥0.15 | - | ≤0.75 | - | ||

- Q: How do you restore the shine on a stainless steel sheet?

- To restore the shine on a stainless steel sheet, you can follow a few simple steps. First, make sure the surface is clean by wiping away any dirt or debris using a soft cloth or sponge and a mild detergent mixed with warm water. Rinse off the soap residue and dry the sheet thoroughly. Next, apply a small amount of stainless steel cleaner or polish to a clean, soft cloth. Gently rub the cleaner in a circular motion onto the stainless steel sheet, focusing on any areas with visible marks or dullness. Be sure to follow the manufacturer's instructions for the cleaner or polish you are using. After applying the cleaner, let it sit on the surface for a few minutes to allow it to work its magic. Then, using a clean portion of the cloth, buff the stainless steel sheet using circular motions until the shine starts to appear. Continue this process until you are satisfied with the results. If you don't have a specialized stainless steel cleaner or polish, you can also use some household items to restore the shine. For example, you can mix baking soda with water to form a paste and apply it to the sheet. Gently rub the paste onto the surface using a soft cloth and rinse it off thoroughly. Additionally, you can use vinegar or lemon juice to remove any stains or spots. Apply a small amount of vinegar or lemon juice to a cloth and rub it onto the stainless steel sheet, then rinse it off and dry it thoroughly. Remember to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This will ensure that it doesn't cause any damage or discoloration.

- Q: Several processing techniques of colored stainless steel

- 1, water plating (mainly black, note 304 plating water plating, color instability, slightly blue, mirror surface is particularly obvious, treatment method for high temperature without fingerprint processing, but the surface will be brown)2, electroplating - PVD vacuum plasma plating (can be plated sapphire blue, black, coffee, seven color, zirconium, gold, bronze, bronze, rose, champagne, golden, light green)

- Q: Do stainless steel sheets have a warranty?

- Yes, stainless steel sheets typically come with a warranty. The length and terms of the warranty may vary depending on the manufacturer or supplier. It is recommended to check with the specific company or review the product documentation for information on the warranty coverage.

- Q: Can stainless steel sheets be used for HVAC systems?

- Yes, stainless steel sheets can be used for HVAC systems. Stainless steel is highly resistant to corrosion and can withstand high temperatures, making it an ideal material for HVAC components such as ductwork, heat exchangers, and exhaust systems. It is also durable and easy to clean, ensuring long-lasting performance in HVAC applications.

- Q: How are stainless steel sheets manufactured?

- Stainless steel sheets are manufactured through a multi-step process that involves several key stages. The production begins with the melting of raw materials, including iron ore, chromium, and nickel, in an electric arc furnace. This process helps to eliminate impurities and create a molten metal. Once the molten metal is obtained, it is cast into slabs or billets. These slabs are then hot rolled, which involves passing them through a series of rollers to reduce their thickness and increase their length. This initial rolling process also helps in refining the grain structure of the steel, making it more uniform. After hot rolling, the steel is pickled and annealed to remove any scale or impurities formed during the initial rolling process. Pickling involves immersing the steel in a bath of acid to remove the surface oxide layer, while annealing is a heat treatment process that helps to reduce internal stresses and improve the steel's ductility. Following pickling and annealing, the steel is cold rolled. Cold rolling involves passing the annealed steel through a set of rollers at room temperature to further reduce its thickness and improve its surface finish. This process also imparts the desired mechanical properties to the stainless steel sheets. Once the desired thickness is achieved through cold rolling, the stainless steel sheets are subjected to various finishing processes. These may include surface treatments like polishing, embossing, or etching to enhance the appearance and texture of the sheets. Additionally, the sheets can be cut to size using shearing or laser cutting techniques. Finally, the stainless steel sheets undergo quality control checks to ensure they meet the required specifications. This includes inspecting the dimensions, surface finish, and mechanical properties of the sheets. Once approved, the sheets are ready for packaging and distribution to various industries that utilize stainless steel in their applications. Overall, the manufacturing process of stainless steel sheets involves a combination of melting, casting, hot rolling, pickling, annealing, cold rolling, and finishing. This meticulous process ensures the production of high-quality stainless steel sheets that possess excellent corrosion resistance, strength, and aesthetic appeal.

- Q: Are stainless steel sheets good for exhaust systems?

- Yes, stainless steel sheets are excellent for exhaust systems. Stainless steel is a popular choice for exhaust system materials due to its high resistance to corrosion, heat, and pressure. It can withstand the extreme temperatures and harsh conditions that exhaust systems are exposed to, ensuring durability and longevity. Stainless steel also has excellent acoustic properties, helping to reduce noise levels. Additionally, stainless steel sheets can be easily formed and welded, allowing for the creation of customized exhaust system designs. Overall, stainless steel sheets are a reliable and efficient material for exhaust systems in terms of performance, aesthetics, and overall functionality.

- Q: Can stainless steel sheets be used for marine propellers?

- Yes, stainless steel sheets can be used for marine propellers. Stainless steel is a popular choice for marine propellers due to its excellent corrosion resistance properties. The high levels of chromium in stainless steel make it resistant to rust and other forms of corrosion, even in saltwater environments. Additionally, stainless steel offers good strength and durability, making it suitable for withstanding the harsh conditions of marine environments. Stainless steel propellers are often preferred for boats and ships as they require less maintenance and have a longer lifespan compared to other materials. However, it is important to choose the appropriate grade of stainless steel for marine propellers to ensure optimal performance and longevity.

- Q: How do stainless steel sheets compare to other materials?

- Stainless steel sheets have several advantages over other materials, making them a popular choice in various industries. Firstly, stainless steel is known for its exceptional durability and strength. It can withstand high temperatures, pressure, and corrosion, making it suitable for a wide range of applications. This durability ensures a longer lifespan and reduces the need for frequent replacements, saving both time and money. Secondly, stainless steel sheets have excellent resistance to corrosion and rust. This property is particularly important in environments with high humidity or exposure to chemicals, as it prevents degradation and maintains the integrity of the material. Other materials, such as aluminum or carbon steel, may require protective coatings or regular maintenance to achieve similar levels of corrosion resistance. Furthermore, stainless steel sheets have a clean and smooth surface finish, making them aesthetically pleasing and easy to clean. This quality is crucial in industries such as food processing, pharmaceuticals, and healthcare, where hygiene and cleanliness are paramount. Stainless steel sheets also offer versatility in terms of fabrication and customization. They can be easily formed, welded, and shaped into different sizes and configurations, allowing for a wide range of applications. This versatility makes stainless steel sheets suitable for architectural, automotive, and industrial uses. Lastly, stainless steel is environmentally friendly. It is 100% recyclable, meaning that it can be melted down and reused without any loss in quality or performance. This recyclability reduces the demand for new materials and lessens the environmental impact associated with manufacturing processes. In summary, stainless steel sheets outperform other materials in terms of durability, corrosion resistance, cleanliness, versatility, and environmental sustainability. These qualities make stainless steel sheets a superior choice for various industries and applications.

- Q: What is the strain hardening exponent of stainless steel sheets?

- The ability of stainless steel sheets to increase their strength and hardness as they undergo plastic deformation or strain is referred to as the strain hardening exponent. This exponent measures how the stress-strain curve of the material changes as deformation increases. Typically, stainless steel sheets have a strain hardening exponent ranging from 0.2 to 0.4. This value signifies that the material experiences a moderate increase in strength and hardness when subjected to plastic deformation. A higher strain hardening exponent indicates a greater resistance to deformation and better ability to maintain its shape under external forces. The strain hardening exponent plays a crucial role in engineering applications as it impacts the material's formability, ductility, and resistance to deformation. Materials with higher strain hardening exponents are preferred in industrial processes like sheet metal forming or cold working as they offer enhanced work-hardening properties. However, excessively high strain hardening exponents can lead to issues such as cracking or material failure. It is important to acknowledge that the strain hardening exponent can vary depending on the specific grade and composition of the stainless steel alloy. Different stainless steel alloys may exhibit distinct strain hardening behaviors, necessitating consideration of the material's properties and specifications when determining the strain hardening exponent for a particular stainless steel sheet.

- Q: Are stainless steel sheets resistant to scratches?

- Yes, stainless steel sheets are generally resistant to scratches. Stainless steel is known for its durability and strength, making it highly resistant to scratching or denting. However, it's important to note that no material is completely scratch-proof, and stainless steel can still develop minor scratches over time with regular use. However, these scratches are usually superficial and can often be easily removed or minimized with proper cleaning and maintenance. Additionally, the level of scratch resistance can vary depending on the grade and finish of the stainless steel sheet.

Send your message to us

Astm 316 321 Stainless Steel Sheets in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords