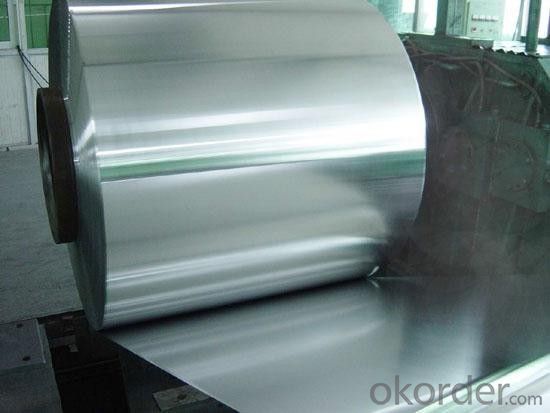

Stainless Steel sheet 304 with Pvd Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430 in china alibaba

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets suitable for architectural applications?

- Yes, stainless steel sheets are highly suitable for architectural applications. Stainless steel is a versatile and durable material that offers numerous advantages for architectural projects. It has excellent corrosion resistance, making it ideal for outdoor applications where it is exposed to harsh weather conditions. Stainless steel is also easy to clean and maintain, ensuring a long-lasting and visually appealing finish. In addition to its functional benefits, stainless steel sheets offer an aesthetic appeal that enhances the architectural design. Its sleek and modern appearance can complement various styles, from contemporary to industrial. Stainless steel can be fabricated into different shapes and sizes, providing architects with ample design flexibility. Furthermore, stainless steel sheets can be used in a wide range of architectural applications. They are commonly utilized for cladding, roofing, and façade systems, adding a distinctive and eye-catching element to buildings. Stainless steel can also be incorporated into interior design elements such as wall panels, handrails, and decorative finishes, contributing to a sophisticated and luxurious atmosphere. Overall, the exceptional properties of stainless steel, combined with its aesthetic appeal and versatility, make it an excellent choice for architectural applications. Its durability, resistance to corrosion, and easy maintenance make stainless steel sheets a reliable and long-lasting option for architects and designers.

- Q: Are stainless steel sheets suitable for food processing?

- Yes, stainless steel sheets are highly suitable for food processing. Stainless steel is widely used in the food and beverage industry due to its excellent properties and hygienic nature. It is non-reactive, corrosion-resistant, and does not impart any flavor or odor to the food being processed. Stainless steel is easy to clean and maintain, making it an ideal choice for food processing equipment, countertops, and other surfaces. It also withstands high temperatures and is resistant to bacterial growth, making it a safe and reliable material for food processing.

- Q: What are the specifications of stainless steel plates? Are they the same width?

- Different specifications, width is not the same, there are 1.22 meters, 1 meters, etc., length, width, thickness are different.

- Q: Can stainless steel sheets be used for exterior cladding?

- Yes, stainless steel sheets can be used for exterior cladding. Stainless steel is highly resistant to corrosion, making it suitable for outdoor applications. It is durable, long-lasting, and provides an attractive aesthetic for building exteriors.

- Q: What is the formability of stainless steel sheets?

- The formability of stainless steel sheets refers to their ability to be shaped or formed into desired geometries without cracking, tearing, or losing their structural integrity. Stainless steel sheets are known for their excellent formability due to their unique combination of strength, ductility, and corrosion resistance. They can be easily bent, rolled, or stretched into various shapes, making them versatile for a wide range of applications. Additionally, stainless steel sheets can maintain their form even under extreme temperatures or harsh environments, further enhancing their formability. However, it is important to note that the formability of stainless steel sheets can vary depending on the specific grade, thickness, and surface finish. Higher grades of stainless steel tend to have better formability, while thicker sheets may require more force to shape. Surface finish, such as cold-rolled or hot-rolled, can also affect formability as it can influence the material's grain structure and mechanical properties. Therefore, understanding the specific characteristics and limitations of the stainless steel sheet being used is crucial in determining its formability for a particular application.

- Q: What is the thickness tolerance for stainless steel sheets?

- The thickness tolerance for stainless steel sheets can vary depending on the specific grade and manufacturing process. However, in general, the typical thickness tolerance for stainless steel sheets is around +/- 0.005 inches or +/- 0.13 millimeters.

- Q: Can stainless steel sheets be used in the medical industry?

- Yes, stainless steel sheets can be used in the medical industry. Stainless steel is a popular material choice in the medical field due to its excellent corrosion resistance, high strength, and durability. It is commonly used for a variety of applications, including medical instruments, surgical tools, dental equipment, implants, and medical equipment. Stainless steel sheets are also easy to clean and sterilize, making them ideal for maintaining hygienic conditions in medical environments. Additionally, stainless steel is biocompatible, meaning it is compatible with human tissues and does not cause any adverse reactions, making it a safe choice for medical applications. Overall, stainless steel sheets are highly suitable for use in the medical industry due to their numerous beneficial properties.

- Q: Are stainless steel sheets resistant to staining from food?

- Yes, stainless steel sheets are highly resistant to staining from food.

- Q: How do I prevent stress relaxation on stainless steel sheets?

- To prevent stress relaxation on stainless steel sheets, it is important to avoid subjecting them to excessive heat or prolonged periods of high stress. Additionally, carefully selecting the appropriate grade of stainless steel and implementing proper handling and storage techniques can help minimize stress relaxation.

- Q: Can stainless steel sheets be used in medical equipment?

- Medical equipment can indeed make use of stainless steel sheets. Due to its exceptional properties like resistance to corrosion, durability, and ease of cleaning, stainless steel is a favored option for medical devices and equipment. It is frequently employed in surgical instruments, implants, hospital equipment, and laboratory tools. The versatility of stainless steel sheets makes them a common choice in the manufacturing of medical equipment as they can be shaped into various forms and sizes. Furthermore, stainless steel is highly biocompatible, meaning it poses no harm to bodily tissues and can be safely used in medical applications. All in all, stainless steel sheets are a dependable and widely accepted material for medical equipment, offering both hygienic qualities and long-lasting performance.

Send your message to us

Stainless Steel sheet 304 with Pvd Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords