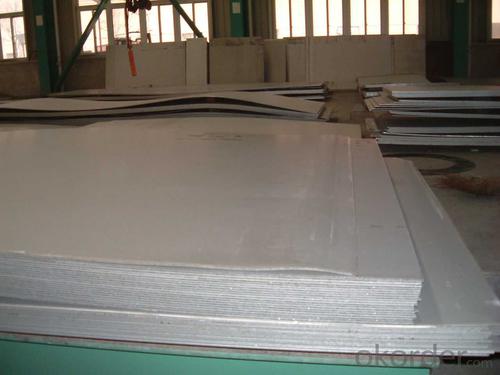

Stainless Steel plate 316L with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/316l/321,410/420/430/444/443/409L, and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: How to clean stainless steel plate cleaning?

- Grease can be applied to soft cloth to dissolve alcohol. I was impressed with how the grease turned off my pizza oven. Some thicker deposits did not respond once to a cloth, but I had been rubbing them with alcohol and completely disappeared within one or two minutes. With other methods, it is important to rinse off the alcohol and dry it so that it has a shiny metal.

- Q: Are stainless steel sheets suitable for decorative applications?

- Yes, stainless steel sheets are suitable for decorative applications. They have a sleek and modern appearance that can enhance the aesthetics of various spaces. Additionally, stainless steel is resistant to corrosion and staining, making it durable and long-lasting, even in decorative settings.

- Q: Can stainless steel sheets be used for countertops?

- Certainly! Countertops can indeed be made using stainless steel sheets. Stainless steel is a material known for its durability and versatility, as it possesses resistance against stains, heat, and bacteria. Consequently, it proves to be an exceptional option for kitchen countertops. Moreover, stainless steel countertops are effortless to clean and maintain, all while presenting a sleek and contemporary look. While commonly found in commercial kitchens, these countertops are steadily gaining popularity in residential settings, owing to their durable nature and hygienic qualities.

- Q: What's the drill for stainless steel?

- The cutting fluid is made of concentrated emulsions. Commonly used stainless steel drills are: high cobalt bit (M35 bit, M42 bit), in which the M42 bit is the most cost-effective, and carbide drills are also available.

- Q: What are the different types of stainless steel sheet grades available?

- There are several different types of stainless steel sheet grades available, each with its own unique properties and applications. Some of the most common stainless steel sheet grades include: 1. Austenitic stainless steel: This is the most widely used type of stainless steel, known for its excellent corrosion resistance and high ductility. It is non-magnetic and can be easily formed and welded. Grades within this category include 304 and 316. 2. Ferritic stainless steel: Ferritic stainless steel is known for its magnetic properties and excellent resistance to corrosion, particularly in high-temperature environments. It is less ductile than austenitic stainless steel but offers good strength and formability. Common grades in this category include 430 and 409. 3. Martensitic stainless steel: Martensitic stainless steel is characterized by its high strength, hardness, and wear resistance. It is often used in applications where toughness and corrosion resistance are less important. Popular grades within this category include 410 and 420. 4. Duplex stainless steel: Duplex stainless steel is a combination of austenitic and ferritic stainless steels, offering a unique blend of strength, corrosion resistance, and cost-effectiveness. It is highly resistant to stress corrosion cracking and is often used in industries such as oil and gas, chemical processing, and marine applications. Common grades in this category include 2205 and 2507. 5. Precipitation hardening stainless steel: Precipitation hardening stainless steel is heat-treatable and offers high strength and corrosion resistance. It is often used in aerospace and high-performance applications where a combination of strength and corrosion resistance is required. Popular grades within this category include 17-4 PH and 15-5 PH. These are just a few examples of the different types of stainless steel sheet grades available. Each grade has its own specific characteristics and is selected based on the desired properties and intended application.

- Q: What is the modulus of elasticity of stainless steel sheets?

- The modulus of elasticity, also known as Young's modulus, is a measure of the stiffness or rigidity of a material. For stainless steel sheets, the modulus of elasticity typically ranges from 190 to 200 gigapascals (GPa). However, it is important to note that the modulus of elasticity can vary depending on the specific type and grade of stainless steel, as well as factors such as temperature and strain rate.

- Q: Do stainless steel sheets require any special maintenance?

- Regular cleaning is necessary to keep stainless steel sheets looking good and preventing corrosion. Unlike other materials, stainless steel is resistant to staining, rust, and corrosion, so it requires less maintenance. However, it is important to clean stainless steel sheets regularly to get rid of dirt, debris, and fingerprints that can make them lose their shine. To clean stainless steel sheets, just use a soft cloth or sponge with mild soap and warm water. Avoid using abrasive cleaners or scrub brushes as they can damage the surface. After cleaning, make sure to dry the sheets thoroughly to avoid water spots or marks. By following these simple cleaning instructions, stainless steel sheets will remain beautiful and functional for many years.

- Q: Are stainless steel sheets good for oil and gas equipment?

- Yes, stainless steel sheets are highly suitable for oil and gas equipment. Stainless steel has excellent corrosion resistance, high strength, and durability, making it an ideal choice for harsh environments and corrosive substances encountered in the oil and gas industry. Additionally, stainless steel's heat resistance and low maintenance requirements further contribute to its effectiveness in this field.

- Q: What are the different types of punched finishes available for stainless steel sheets?

- There are several different types of punched finishes available for stainless steel sheets, each offering unique characteristics and benefits. Some of the most common punched finishes include: 1. Round Hole: This is the most basic and widely used punched finish. It features evenly spaced round holes that provide good airflow and visibility. It is commonly used in applications such as ventilation systems, decorative panels, and filters. 2. Square Hole: Similar to round hole punched finish, square hole punched finish offers a clean and modern look. It is often preferred when a more geometric pattern is desired. Square hole punched sheets are commonly used in architectural applications, screens, and fencing. 3. Slotted Hole: Slotted hole punched finish is characterized by elongated holes that provide larger openings for increased visibility or improved drainage. It is commonly used in applications such as grilles, sunshades, and safety barriers. 4. Hexagonal Hole: Hexagonal hole punched finish features hexagon-shaped holes that offer a unique and aesthetically pleasing pattern. It is commonly used in decorative applications, such as wall cladding, signage, and artistic installations. 5. Decorative Patterns: In addition to the standard punched finishes, there are various decorative patterns available for stainless steel sheets. These patterns can include custom designs, logos, or intricate shapes, adding a personalized touch to any project. The choice of punched finish depends on the specific requirements of the application, including aesthetics, functionality, and performance. It is important to consider factors such as hole size, open area percentage, strength, and corrosion resistance when selecting the appropriate punched finish for stainless steel sheets.

- Q: Stainless steel wire drawing without fingerprints, what principle?

- Let's say the principle: the material surface is easy to leave the fingerprint because the material has the characteristics of specular reflection on the light. The material is smooth enough, and the light is not diffusely reflective on the material, mainly specular. Landlord with your finger press the glass mirror will know

Send your message to us

Stainless Steel plate 316L with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords